Blog Filters:

-

How Weiland Doors Automates Custom SOLIDWORKS Models, Drawings, and BOMs in Minutes

Ensuring Design Consistency and Reducing Errors with DriveWorks Manufacturers that build highly customized products face a familiar challenge. As demand grows, engineering teams are asked to deliver more variations, faster, without…

-

CAMWorks Tips and Tricks That Improve Toolpath Quality and Save Time

If you use SOLIDWORKS CAM or CAMWorks, you have probably seen at least one of these headaches: In a recent GSC training session, Applications Engineer Alejandro Murillo walked through practical…

-

60 Years Of SOLIDWORKS

Well, the day has finally arrived. November 14, 2025 marks the 30th birthday of SOLIDWORKS as a publicly released software package. While people were able to purchase beta copies at…

-

From Beta to 8 Million Users: 30 Years of SOLIDWORKS Innovation

Thirty years ago, “3D CAD on Windows” sounded more like a bet than a business plan. In 1995, the very first SOLIDWORKS beta ran on the brand-new Windows 95—and a…

-

Ellison Technologies Showcases End-to-End “Journey of the Part” Initiative, Leveraging CADchat to Unite Teams and Drive Manufacturing Innovation

FOR IMMEDIATE RELEASE Santa Fe Springs, CA – Sept 25 – Ellison Technologies has announced the successful launch of its Journey of the Part initiative, a national event series designed…

-

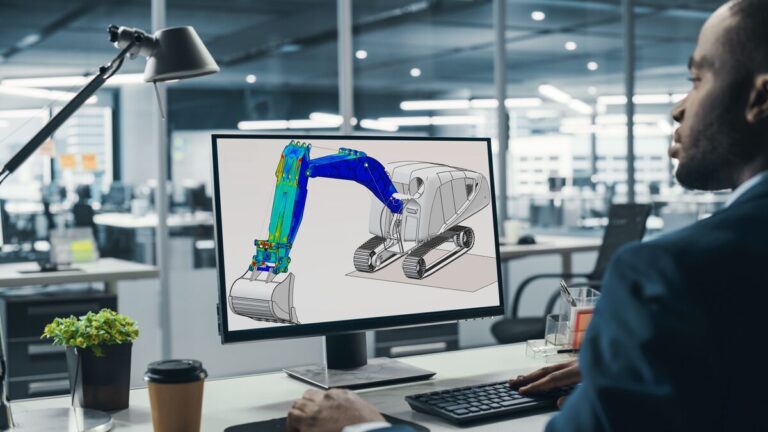

How SOLIDWORKS CAD and Simulation Save Time and Money with Virtual Testing

Prototyping is essential for creating reliable, high-performing products—but physical prototypes can be expensive and time-consuming to produce. By combining SOLIDWORKS CAD with SOLIDWORKS Simulation, engineering teams can test product performance…

-

The Stronger, the Cheaper, the Better: Markforged 3D Printed Parts

What makes Markforged untouchable in the 3D printing industry? Compare surface finishes, heat resistance, and unparalleled part strength through Continuous Fiber Reinforcement at a truly affordable price.

-

Boost Your SOLIDWORKS Performance with Dell + NVIDIA Workstation Savings

Is your current workstation keeping up with the demands of your SOLIDWORKS workflows? Whether you’re upgrading aging hardware or adding new seats for your expanding team, now is an ideal…

-

Integrating Quality with DELMIAWorks: Strategies for Smarter Manufacturing

Know Where You Stand — and Where to Improve You can’t improve what you don’t measure. That’s why establishing clear, data-driven baselines is critical. Why Quality Is Your Best Competitive…

-

Improve Production Performance with Real-Time Monitoring with DELMIAWorks

DELMIAWorks is an all-in-one ERP and MES solution for discrete manufacturers. It offers real-time visibility and control over production, inventory, finance, and quality, helping businesses streamline operations, boost efficiency, and…

-

What is Cloud PDM?

How is Product Data Stored and Accessed in the Cloud? When talking to anyone current with Product Data Management technology, mention “the cloud,” and you’ll soon be discussing software-as-service (SaaS).…

-

Five Reasons GSC Should Upgrade Your PDM

Upgrading SOLIDWORKS PDM, at least annually, should not be considered optional. Nevertheless, there are a few reasons that compel people to defer the undertaking to the future. One reason, saving…

-

Unlocking Efficiency: How DriveWorks Transforms Custom Product Design in SOLIDWORKS®

In today’s fast-paced manufacturing world, customization is king. But with custom products comes the pressure to turn around designs, proposals, and documentation faster than ever. For many engineering teams, this…

-

3D EXPERIENCE WORLD 2025: KEY TAKEAWAYS

Every year, 3DEXPERIENCE World brings together engineers, designers, and manufacturers from around the globe to explore the latest advancements in technology. The 2025 event was no exception, delivering exciting updates,…

-

Top 3 Challenges in Consumer Goods Manufacturing (And How Technology Solves Them)

The consumer goods industry is under constant pressure to deliver innovative products faster, cheaper, and with greater precision. However, manufacturers face significant challenges that can hinder their ability to meet…

-

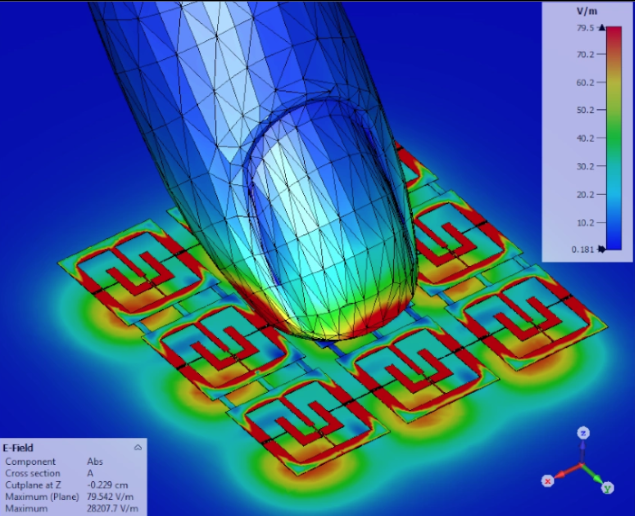

What Electromagnetic Simulation Software is the Best?

Electromagnetic simulation is crucial across various industries, from aerospace and automotive to healthcare and consumer electronics. Engineers need powerful, precise, and user-friendly software to model electromagnetic interactions effectively. While ANSYS…

-

How Cloud Data Management is Transforming Manufacturing

The manufacturing industry is evolving rapidly and staying competitive means embracing tools that optimize efficiency and collaboration. Cloud data management is one such tool, revolutionizing the way manufacturing teams handle…

-

Using Simulation to Perfect Product Design for Everyday Use

In the highly competitive world of consumer goods, getting a product to market quickly without compromising quality is essential. Yet, creating products that are both functional and durable, while meeting…

-

Navigating Marine Industry Challenges with Advanced Solutions

The marine industry faces unique challenges, from withstanding harsh environments to meeting sustainability goals. Advanced engineering tools and materials are essential for manufacturers to tackle these issues effectively. Here’s a…

-

5 Signs Your Team Needs PDM

Managing design data can be challenging for any engineering team, especially as projects grow in complexity. Without an efficient data management system, even the most talented teams can face unnecessary…

-

Computing Power Tuned to Your Engineering Applications Use Case Is Critical

In today’s world, having an engineering platform that is perfectly tuned to your needs is more important than ever. GSC, in partnership with Dell and NVIDIA, is offering you the…

-

Driving Automotive Excellence: Unlocking the Potential of Advanced Applications

The automotive industry is navigating a transformative era. With advancements in electric vehicles, sustainability initiatives, and the demand for lightweight yet durable components, manufacturers are rethinking how they design, test,…

-

Announcing New Capabilities and Exclusive Savings with the Dell/NVIDIA/GSC Partner Program

The Dell/NVIDIA Partner Program offers GSC customers personalized resources to streamline their tech needs and save money. Gain direct access to a named Dell contact who understands your business, ensuring…