Traditionally, manufacturing has been associated with mass production, where large quantities of identical parts are produced to meet market demands. However, a paradigm shift has occurred with the advent of 3D printing technology, allowing for low-volume part production on demand.

Let’s take a deeper look at how 3D printing contributes to the creation of a digital inventory and enables efficient, cost-effective, and flexible production of low-volume parts.

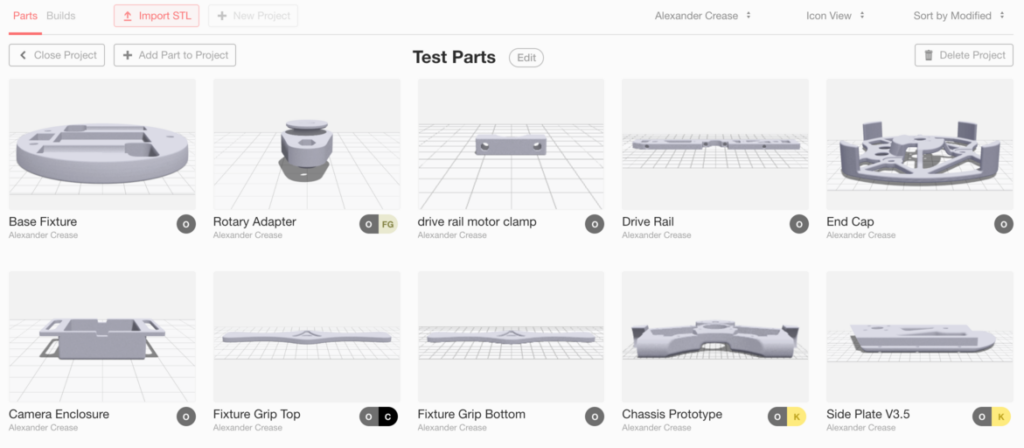

The Rise of Digital Inventory

In the era of digitalization, businesses are embracing the concept of digital inventory, where part designs are stored digitally instead of physically stocking physical parts. This shift offers numerous advantages, including reduced storage costs, elimination of inventory obsolescence, and streamlined supply chains. 3D printing plays a pivotal role in realizing the potential of digital inventory by providing the means to produce physical parts only when needed.

Efficiency in Low-Volume Production

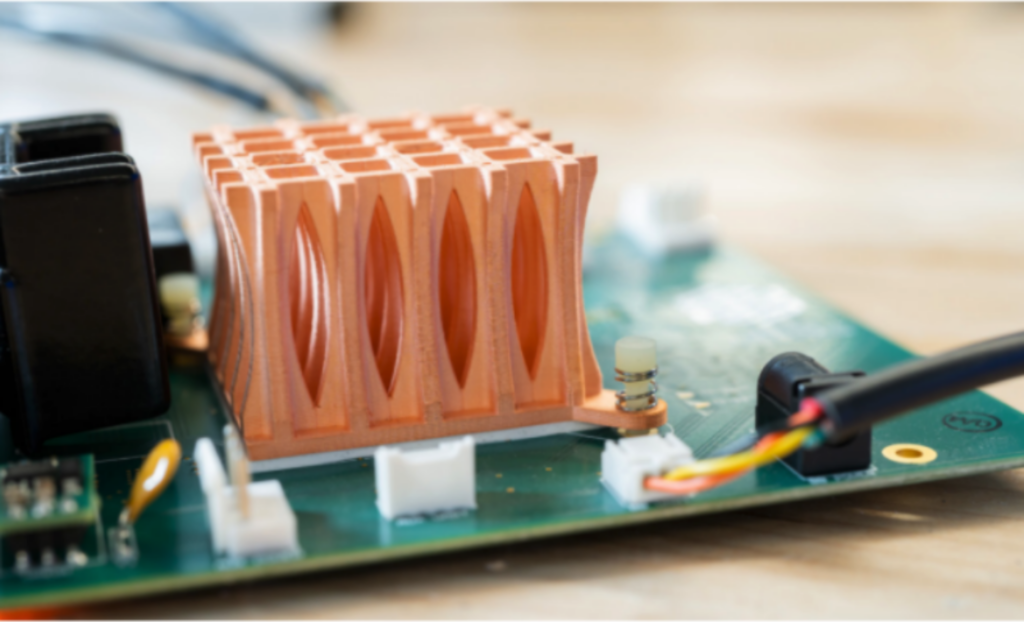

3D printing excels in low-volume production scenarios, where traditional manufacturing methods prove inefficient, cost-prohibitive, or geometrically complex. Rather than investing in expensive tooling and machinery for producing small quantities of parts, 3D printing allows for direct production from digital designs, bypassing the need for costly setups. This efficiency significantly reduces production lead times, eliminates excess waste, and lowers associated costs.

Cost-Effectiveness

Low-volume production using traditional methods often incurs high setup costs, making it economically unviable for small-scale manufacturing. In contrast, 3D printing enables cost-effective production of low-volume parts by eliminating the need for custom tooling and molds. The digital nature of 3D printing allows for rapid design iteration and customization without incurring additional expenses. Furthermore, as 3D printing technologies advance, the cost of printers and materials decreases, further enhancing its cost-effectiveness.

Design Flexibility

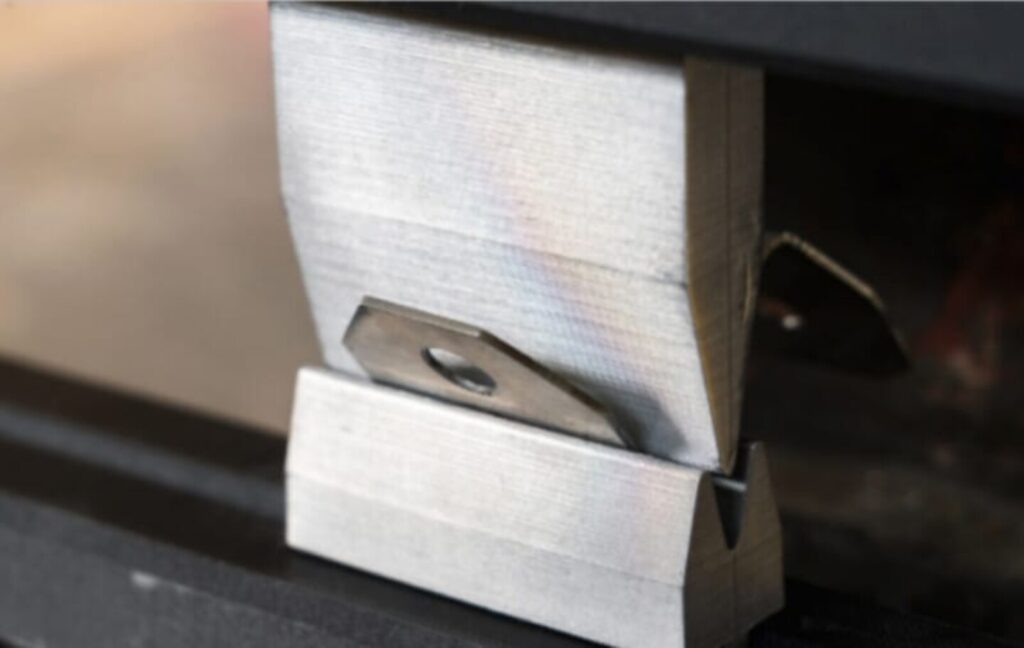

One of the greatest advantages of 3D printing is its design flexibility. Traditional manufacturing methods often impose constraints on part geometries and structures due to the limitations of tooling and machining processes. 3D printing, on the other hand, embraces the concept of additive manufacturing, allowing for the creation of complex geometries, intricate details, and customized features. This design freedom enables manufacturers to produce highly tailored parts that meet specific requirements and perform optimally.

Reduced Supply Chain Complexity

The use of 3D printing for on-demand low volume part production simplifies supply chain logistics. Instead of relying on complex networks of suppliers and warehouses, businesses can maintain a digital inventory and produce parts locally, eliminating the need for long lead times and transportation costs. This localized production reduces the complexity of the supply chain, enhances responsiveness to customer demands, and enables a just-in-time production approach.

Sustainability and Waste Reduction

3D printing aligns with sustainable manufacturing practices by minimizing material waste. Traditional manufacturing methods often result in significant material waste during production due to machining, cutting, and molding processes. 3D printing, being an additive manufacturing technology, only uses the necessary amount of material required to build the part, reducing waste and minimizing environmental impact.

3D printing has changed the way low volume parts are produced, enabling on-demand manufacturing from a digital inventory. The combination of digitalization, efficiency, cost-effectiveness, design flexibility, simplified supply chains, and sustainability positions 3D printing as a powerful tool for low volume production. As this technology continues to advance and more materials become available, the potential for on-demand manufacturing through 3D printing will further expand, opening new opportunities for businesses to respond to market demands quickly and effectively.

Contact Us

Interested in delving deeper into metal or composite 3D printing or would like to schedule a visit to see the technology in-person? Get in touch with one of our experts: 800-454-2233.

Share

Meet the Author