In today’s competitive industrial landscape, manufacturers constantly strive to improve their equipment’s efficiency, reliability, and performance. Companies are using advanced simulation software solutions like SIMULIA to meet these goals. Powered by the 3DEXPERIENCE platform from Dassault Systèmes, SIMULIA delivers realistic simulation applications that enable users to reveal the world we live in. This powerful suite of simulation tools empowers industrial equipment manufacturers to optimize their designs, reduce costs, and accelerate time-to-market.

Let’s dive into the capabilities of SIMULIA and explore how it benefits manufacturers in the realm of industrial equipment:

Understanding SIMULIA

SIMULIA is a comprehensive suite of simulation tools that enable manufacturers to predict product behavior and performance under real-world conditions. It encompasses various analysis capabilities, including structural analysis, thermal analysis, fluid dynamics, motion analysis, and more. By leveraging these simulation capabilities, industrial equipment manufacturers can gain valuable insights into the behavior of their designs before physical prototypes are built, saving time and resources.

Virtual Prototyping and Design Validation

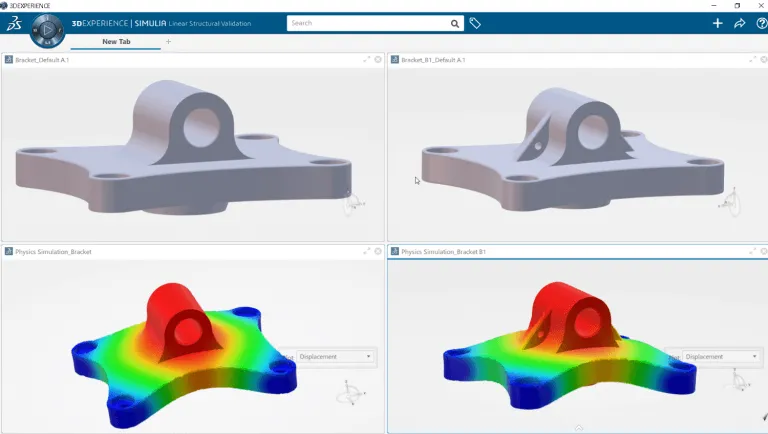

One of the key advantages of SIMULIA is its ability to perform virtual prototyping and design validation. Manufacturers can simulate and evaluate the performance of their equipment in various operating conditions, identify potential design flaws or weaknesses, and optimize the design to enhance reliability and efficiency. This iterative process helps to minimize costly physical prototyping iterations, reducing development time and accelerating time-to-market.

Structural Analysis

SIMULIA’s structural analysis capabilities enable engineers to simulate and evaluate the structural integrity of their equipment, ensuring that their products can withstand the demanding operational conditions they are subjected to. Engineers can predict stress, deformation, fatigue life, and failure points, allowing them to optimize designs for enhanced strength and durability.

Thermal and Fluid Analysis

Many industrial equipment applications involve complex heat transfer and fluid flow phenomena. SIMULIA’s thermal and fluid analysis capabilities allow manufacturers to simulate and analyze these critical aspects. Engineers can evaluate temperature distribution, heat dissipation, fluid flow rates, pressure drops, and more. Manufacturers can optimize thermal management and fluid dynamics by improving energy efficiency, performance, and overall product reliability.

Motion Analysis

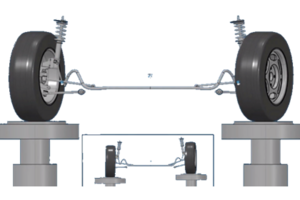

In the realm of industrial equipment, understanding and optimizing motion is crucial. SIMULIA’s motion analysis features enable manufacturers to simulate and evaluate their equipment’s kinematic and dynamic behavior. Engineers can analyze forces, accelerations, velocities, and trajectories, allowing them to optimize designs for smoother operation, reduced wear and tear, and enhanced safety.

Collaboration and Integration

SIMULIA seamlessly integrates with the broader SOLIDWORKS ecosystem, providing a unified platform for design, simulation, and manufacturing processes. This integration fosters collaboration among interdisciplinary teams, allowing designers and engineers to work together more effectively. Manufacturers can make informed decisions and optimize designs for superior performance and reliability by sharing simulation data and insights.

In the competitive landscape of industrial equipment manufacturing, SIMULIA emerges as a powerful ally for optimizing design, improving efficiency, and enhancing performance. By leveraging its advanced simulation capabilities, manufacturers can gain valuable insights into their products, reduce development time, and bring high-quality equipment to market faster. With SIMULIA, industrial equipment manufacturers can achieve the twin goals of driving innovation and meeting the demands of an ever-evolving industry.

Watch On-demand: Learn more about Advanced Simulation Tools

Learn about the infinite potential of virtual prototyping with SIMULIA.

Contact us

Have a question? We’re always available to talk over the phone at 262-790-1080, for you to leave a message or for you to submit a request – just contact us.

Share

Meet the Author