How-To Guide eBook: Increase Profitability by Reducing Non-Value Added Work in Engineering

We’ve all heard the popular phrase, “People, Process, and Technology.” These three little words when married together can create a successful engine for your business (some now argue that the People, Process, and Technology triangle has become a diamond – by adding a fourth criteria with Data. And it’s true – having quality data will drive your initiatives and metrics for success).

But which of these three, or four, needed elements is the most valuable? Some might argue Technology, because without the proper, powerful tools in place to maximize efficiency, you won’t see the same level of success as your competitors. Valid.

Some might argue Process. Without a replicable, thorough process, details will be missed and lead to low customer satisfaction. Employee turnover will mean the loss of internal knowledge that transparent processes keep front-and-center.

But I am going to argue People. People are the most valuable element in any successful business engine. And not just any run-of-the-mill type of person.

People Power Progress: Top Performing Companies & Employees

Your top performers lead the way. They give you a model to build upon in your organization, so that you can structure workflow and work performance expectations in your teams. They are known for, and make doubly sure, they are working with the most up-to-date data, and are consistent with their time management. (At the same time, it takes leadership and management teams being present and watchful, to give those performers the green light in access to Technology and time to establish Processes. It alllllll revolves around the People, my friends.)

And that’s all fine and dandy, you might say, but what if you only have one or two top performers on your current team? Or, what if you’re of the opinion that you don’t have any, and you want to mimic your competition? Because it’s a valid thought that the skills inherent in product design, product pitches, sales, etc., whatever your bread and butter department might be – the skills inherent in your performer aren’t easily replicable to the rest of your team. They have other strengths and skillsets that are valuable and balance that top performer’s weaknesses.

Which leads us back to Technology and Process.

Technology & Process: Allow People to Execute Effectively

This – I’d argue – is where Technology and Process swoop in to save the day. You have the benchmark set for success by your top performer. You know the gaps in product data management and time management for other team members, that are often reflective of clunky former habits and lack of the right tools. Bridge the gap with proven process changes and effective technology. Make reaching that barometer of success more easily attainable because you’ve equipped all players with the tools and processes to do so.

Common Data Management Hurdles

As Tech Clarity argues in their research eBook, data management hurdles that take time away from quality design work are:

- Continuously searching for information and data among disparate places

- Collecting data from those disparate resources at the request of other people

- Figuring out how to incorporate changes made by others in the design, that you were never made aware of

- Recreating data you couldn’t find or that was lost

- Checking data in and out

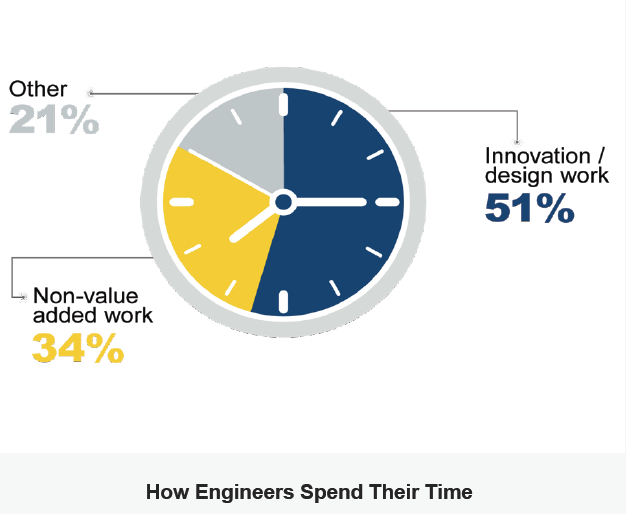

All of this accounts for about 34% of an engineer’s time, that is arguably a time suck. However, these wasteful tasks can be eliminated when the right product data management (PDM) or product lifecycle management (PLM) system is put into place.

Best Practices & Recommendations

Please read the Tech Clarity eBook for yourself, but the key differentiator to the surveyed companies in Tech Clarity’s study is that these Top Performing companies and team members are 2X more likely to have maintained up-to-date models than their peers. Real-time updates were made possible by having a better ‘work space’ – by working in an integrated design and development environment.

- Track how your engineers are spending their time, with the goal of transparency leading to more interesting design time and collaborative work

- Know what top performance as a company, department, team, and individual look like to set barometers for success

- Consider PLM or PDM to centralize design information and make change management easier

- Continually evaluate whether your people have the technology and the processes to be successful and make your company successful

Next Steps: Identify What You Need

Did you find the data and these recommendations useful? Do you want to act on what you’ve learned? Even reading a little bit further and expanding your knowledge on this is welcome. Here are some of our related pages offering the technology and services needed for great data management and the best practices that produce top performing companies:

- Product Data Management (PDM) – Desktop SOLIDWORKS

- Product Lifecycle Management (PLM) – 3DEXPERIENCE on the Cloud

- PDM Implementation through GSC

- SOLIDWORKS Productivity Assessments

- GSC About Us: Who We Are

Contact Us

Have a question? We’re always available to talk over the phone at 262-790-1080, for you to leave a message or for you to submit a request – just contact us.

Want More?

If you’re interested in SOLIDWORKS and other resources:

Share

Meet the Author