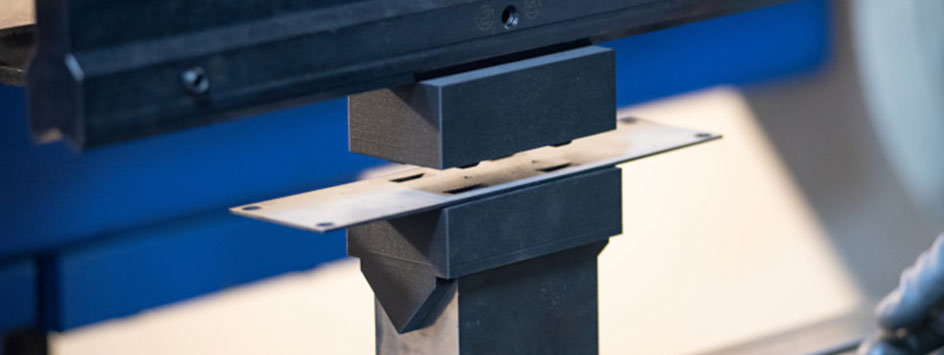

Weld Fixturing

Reduced fabrication cost

SDHQ Off-Road reduced time from 156 hrs. to 12 hrs.

Custom Fit

Custom fixturing can more effectively secure parts that need to be welded.

Durability

Materials produce strong fixtures with high heat resistance.

Save Time & Money

Dramatically reduce fixture assembly and welding setup times.

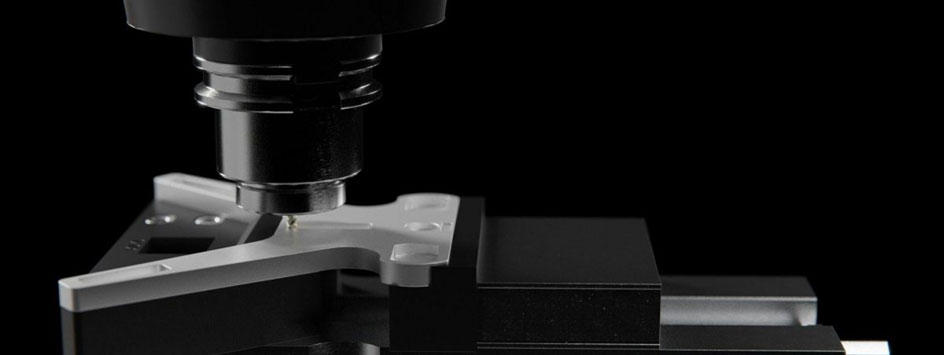

Inspection Fixture

JJ Churchill reduced lead time from 10 days to 3 days

JJ Churchill reduced costs from $1,590 to $330

High Dimensional Accuracy

Precision-machined hardware creates highly stiff, strong, and precise fixtures to measure part tolerances quickly.

Custom Fit

Test against design intent to ensure parts satisfy basic tolerances and are within spec.

Save Time & Money

Quickly produce strong, intricate, form-fitting fixtures at a low cost.

End of Arm Tooling

Dixon Valve reduced costs from $290 to $9

Reduced lead time from 144 hrs to 9 hrs.

Save Money

Rapidly create custom workholding and manipulation tools at a fraction of the cost of machined counterparts.

Save Time

Print custom tools in a matter of hours to meet changing manufacturing needs.

Lightweight Parts

High strength to weight ratio. Maximizes payload grippers can carry.

Soft Jaws

Reduced time from 3 weeks to 1 week

Reduces fabrications costs from $6,000 to $1,500

Easy to Design

Quickly create a conformal, non-marring grip surface that's perfectly fitted to the part to be held.

Save Time & Money

Eliminate time-consuming and expensive CNC processing. 3D print soft jaws overnight.

Specialized Applications

Create custom workholding for complex applications. Streamline workflows.

End-use Parts

Stanley Black and Decker reduced lead time

Stanley Black and Decker reduced fabrication costs

Save Money

Print custom end-use parts on-demand at a fraction of the cost of machined parts.

Save Time & Money

Ideal for cost-effectively printing low-volume parts as needed. Reduce parts inventory. Respond faster to ad-hoc needs.

Lighter Parts

Closed-cell lattice infills reduce part weight while preserving strength.

Molding Tools

Humanetics reduced time from 144 hrs to 66 hrs

Humanetics lowered costs from $1,000 to $240

Save Money

Reduce labor and material/scrap costs by printing customized molds.

Durability

Printed molds can withstand high temperatures and pressures.

Saving Time

Print custom and complex molds and have them ready to use in a few days.

Tooling Development

Time reduced from 10 days to 1.25 days

Centerline Engineering Solutions reduced costs from $1,400 to $200

Improved Ergonomics

Iterate designs faster and create better working tools to speed up efficiency and productivity.

Accuracy

Precision-machined hardware, advanced sensors, and unique software drive leading-edge accuracy and reliability.

Print On-Demand

3D print high quality, robust parts at the point of need.

Functional Prototyping

Centor reduced time from 156 hrs to 12 hrs

Centor reduced costs from $800 to $10

Print On-Demand

Test the functionality of your part and 3D print high-quality, robust parts at the point of need.

Save Money

Create functional prototypes in-house, with minimal labor, and eliminate the need for tooling.

Iterate Faster

Get products to market faster with shorter lead times.

Complex Bracketry

Hugard Inc reduced time from 144 hrs. to 6 hrs.

Hugard Inc reduced costs from $400 to $25

Geometric Freedom

Print strong, complex brackets that are customized for each job.

Save Time

Custom-printed brackets and fixtures help speed machine setups.

Saving Money

Accurate brackets and fixtures eliminate machining costs.

DON'T SEE YOUR APPLICATION?

Let us assess your needs and align you with the right technology for your application.