In today’s fast-paced product development landscape, there is a growing demand for smart electronic gadgets that are smaller in size and require more miniaturized components. To keep up with these trends and successfully introduce innovative products, manufacturers need to implement efficient and integrated design solutions that can help them save time, control costs, improve quality, increase collaboration, and boost innovation.

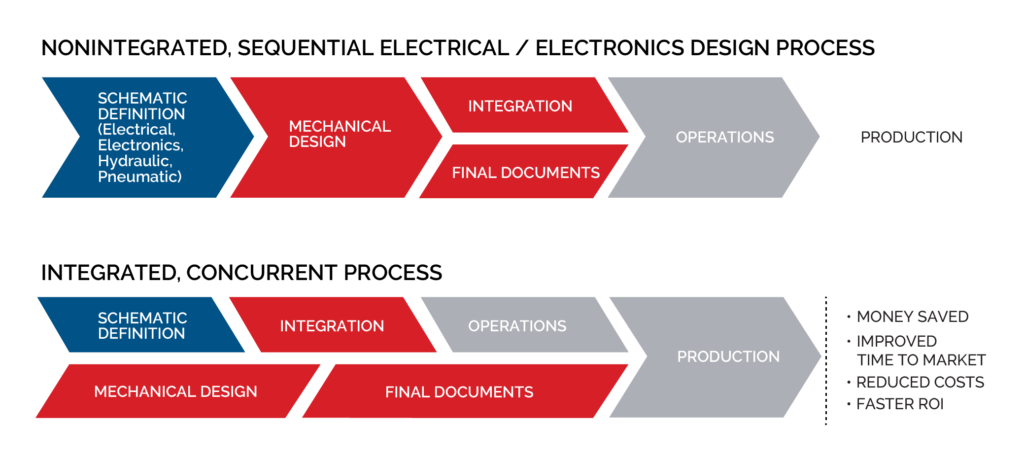

Traditional product development approaches that involve separate workflows for electrical, electronics, and mechanical designs can lead to trade-offs in terms of time, cost, and product features. This can result in islands of automation, engineering discipline tunnel vision, unnecessary and duplicative work, and greater potential for errors, schedule delays, budget overruns, and field failures.

To address these challenges, manufacturers can benefit from moving to a more streamlined, integrated, and collaborative approach to electrical design. By implementing integrated SOLIDWORKS electrical solutions, manufacturers can shorten time to market, improve quality, and increase opportunities for innovation. Learn more about the benefits of an integrated electrical design environment and how it can help manufacturers create innovative products more quickly and cost-effectively.

Limitations of Nonintegrated Electrical Design Processes

- It Takes Too Long

- It Costs Too Much

- It can Lead to Less than Desirable Quality

- It can Stifle Innovation

Conventional, nonintegrated approaches to electromechanical system and product development—whether conducted sequentially or iteratively—not only add time and cost to the development process, but they can also negatively impact product quality and limit innovation. While these nonintegrated approaches often produce finished products, they limit how quickly, cost-effectively, and accurately manufacturers can design, validate, manufacture, and assemble them. More importantly, conventional development methods—with separate efforts for PCB design, electrical schematics, wiring, and mechanical housing and component design—inhibit multidisciplinary collaboration and stifle design innovation.

Benefits of Streamlined, Collaborative, and Integrated Electrical Design Processes

- It’s Faster

- It’s more Cost Effective

- It Delivers Consistently Higher Levels of Quality

- It Enables Motivation

Using an integrated electromechanical design environment like SOLIDWORKS to develop products containing electrical, electronics, and mechanical components and assemblies provides a wide range of benefits. With an integrated approach, manufacturers can shorten design cycles, improve quality, and facilitate manufacturing and assembly. By embracing a multidisciplinary, collaborative development environment—with PCB board design, electrical schematics and wiring, and mechanical housing and component design completed in an integrated manner—manufacturers can stimulate ideas and new ways of thinking that result in innovation.

Streamline Electrical Design with Integrated SOLIDWORKS Electrical Solutions

By using integrated SOLIDWORKS electrical solutions, manufacturers can save time, reduce costs, improve quality, collaborate better, and increase innovation in developing and integrating electrical, electronics, and mechanical components and assemblies.

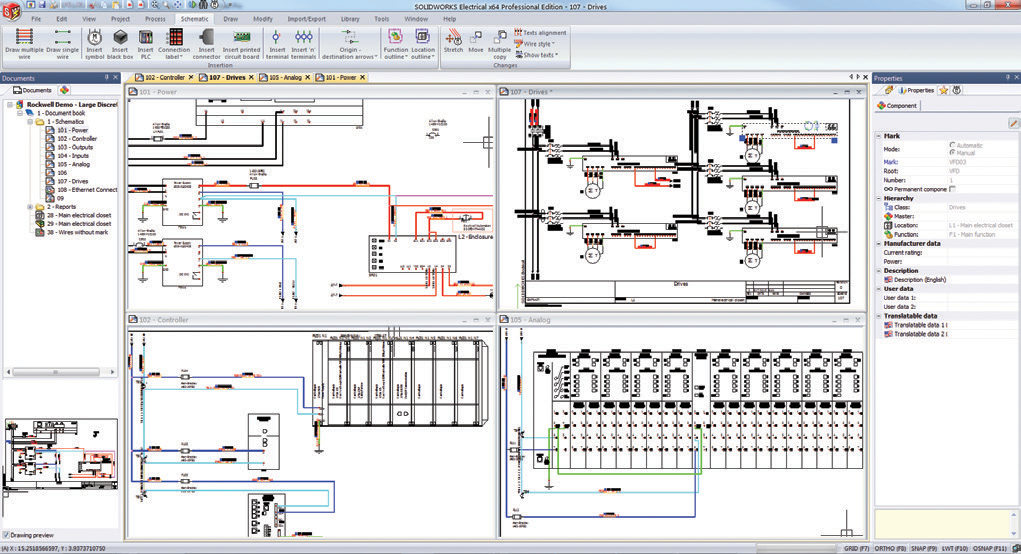

1. SOLIDWORKS Electrical Schematic

SOLIDWORKS Electrical Schematic packages provide standalone, easy-to-use electrical design tools that enable you to define electrical interconnections for complex electrical systems efficiently.

Why Choose? SOLIDWORKS Electrical Schematic has an intuitive, easy-to-use interface that automates complex tasks like contact cross-referencing and terminal drawings. It accelerates product development by simultaneously minimizing the repetitive tasks associated with developing electrical schematics.

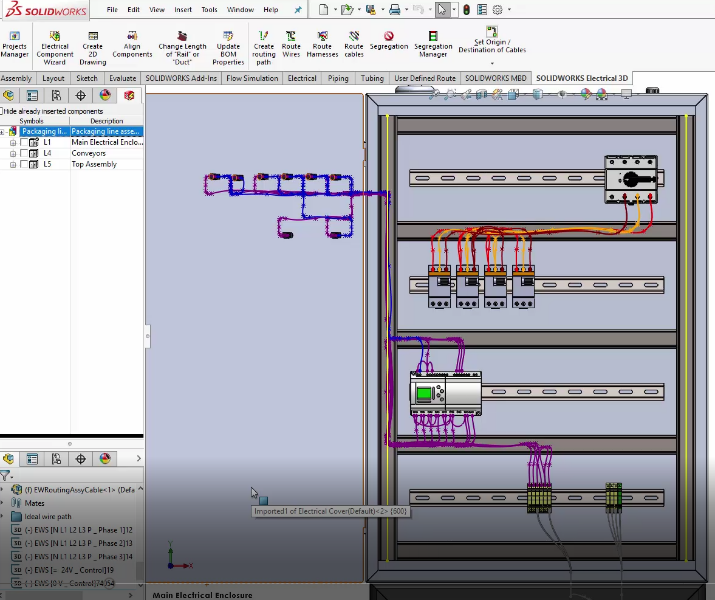

2. SOLIDWORKS Electrical 3D

SOLIDWORKS Electrical 3D enables you to easily integrate your electrical schematic designs into your SOLIDWORKS 3D product model.

Why Choose? SOLIDWORKS Electrical 3D lets you place electrical components and use SOLIDWORKS routing technology to interconnect electrical design elements within a 3D model automatically. 2D schematics and 3D models are synchronized, so any changes are automatically updated.

Learn More

Webinar: Watch our on-demand webinar: Schematic Design Made Easy

Blog: The Journey of a Part in SOLIDWORKS Electrical: From Part to Report to Export

Contact us

You’re passionate about your business. We’re passionate about fueling your success. Reach out today, and let’s start a conversation.

Get in touch with one of our experts: 800-454-2233

Share

Meet the Author