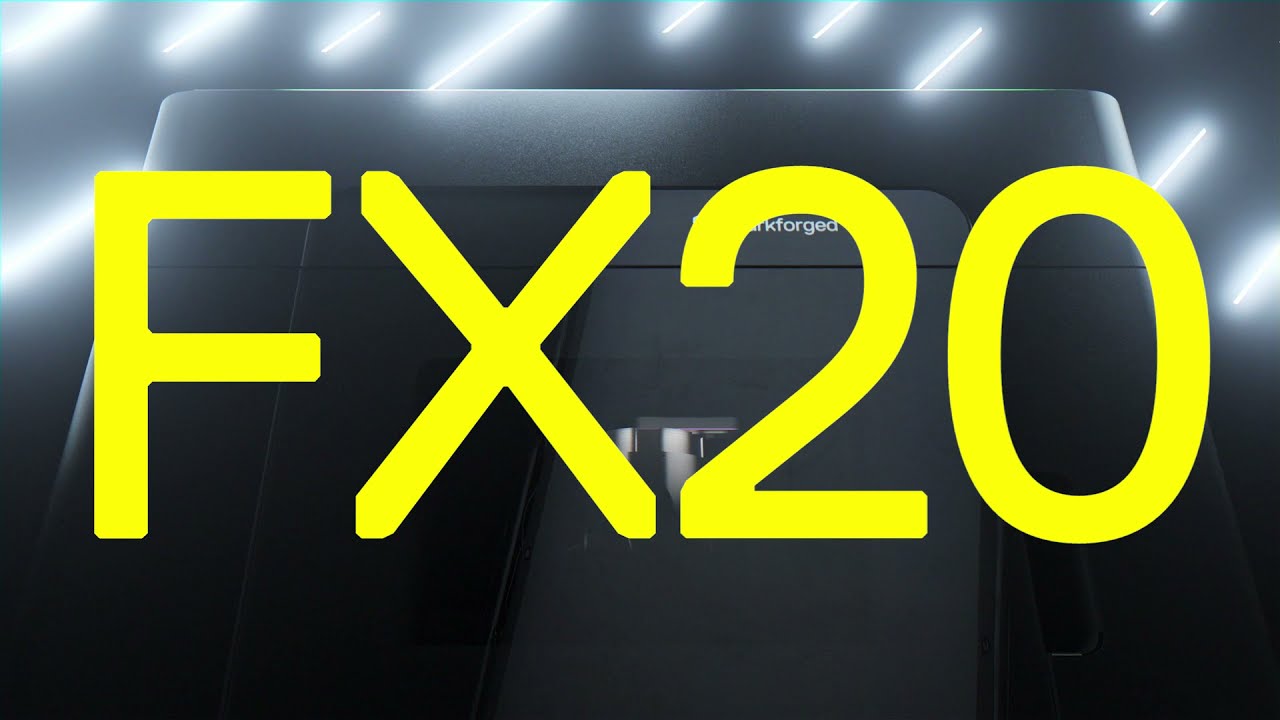

Markforged FX20

The FX20 is the biggest industrial 3D printer allowing you to create massive builds

ULTEM™ 9085 Filament

Onyx Filament

Nylon White Filament

Fiberglass Filament

Kevlar Filament

Carbon Fiber Filament

HSHT Fiberglass Filament

Onyx ESD Filament

Onyx FR Filament

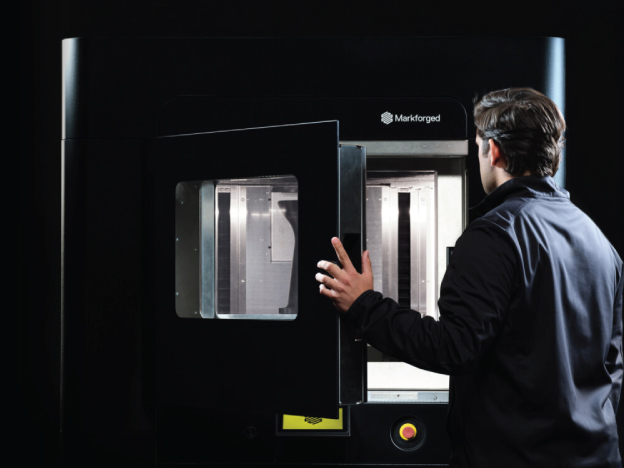

FX20

FX20 is Markforged’s new flagship 3D printer – capable of printing larger and more sophisticated parts faster than any other Markforged 3D printer. This next-generation additive manufacturing platform prints high-temperature thermoplastics reinforced with continuous fiber. These composite parts can withstand some of the world’s most demanding applications, including aerospace, defense, automotive, and oil and gas.

Bigger, Faster, Stronger

Test Drive FX20

Get your first look under the hood of the new flagship printer, the FX20. Experience it yourself in the virtual tour.

Whether your needs are tooling, prototypes, or production parts, FX20 is ready to push the boundaries of additive manufacturing by enabling the efficient production of large, lightweight, advanced composite parts.

With the FX20 you can rapidly iterate and create large, heat-resistant, and stronger production-grade parts 5 times faster than any other 3D printer.

The FX20 prints rugged parts that can withstand high temperatures in some of the toughest environments and demanding applications. Reinforce ULTEM 9085 filament with continuous carbon fiber and build anything from tooling and fixtures to flight-ready parts.

Unlock New Possibilities with Continuous Fiber Technology

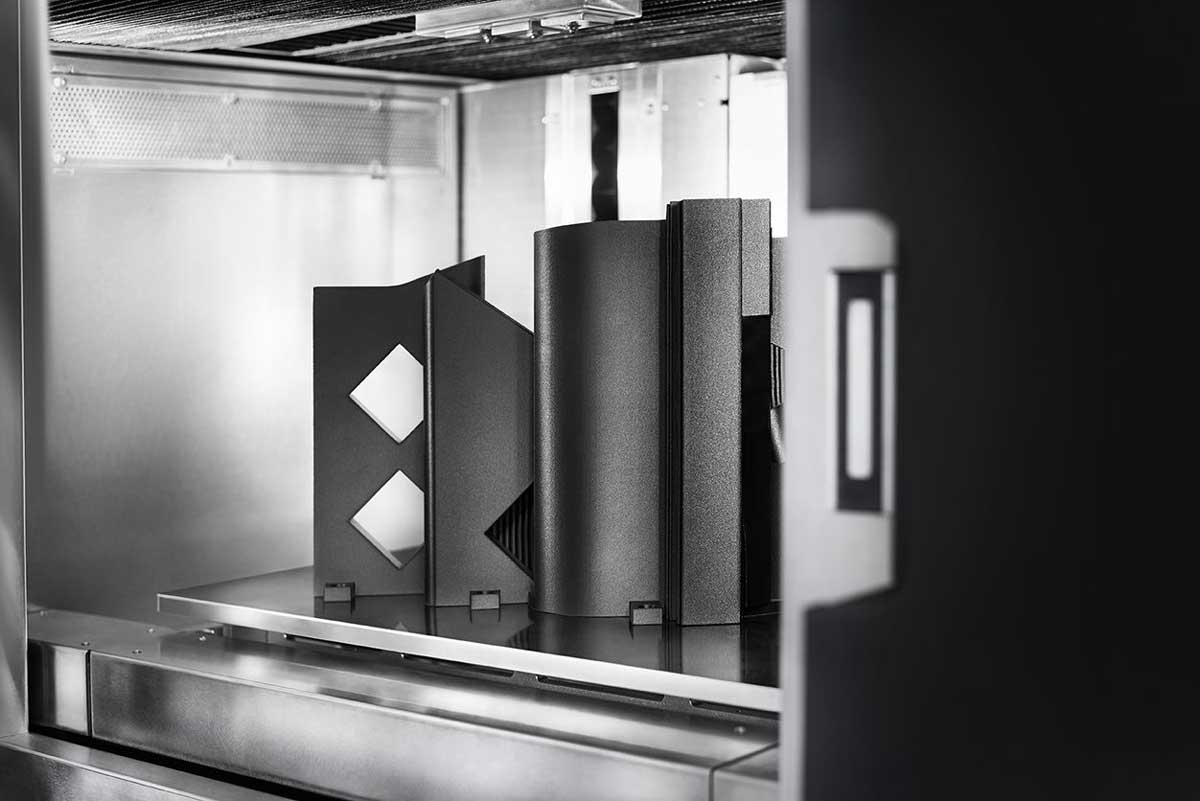

Massive builds

Build Volume: 20.6 X 15.7 X 15.7 inches

The FX20 is Markforged's biggest 3D printer, printing parts up to 5 times larger than its next-largest printer, the X7. Its newly developed motion and extrusion technologies allow the FX20 to retain a high-quality surface finish while printing at significantly faster speeds. Turbo Mode enables you to build up to eight times quicker than Markforged's current line of composite printers.

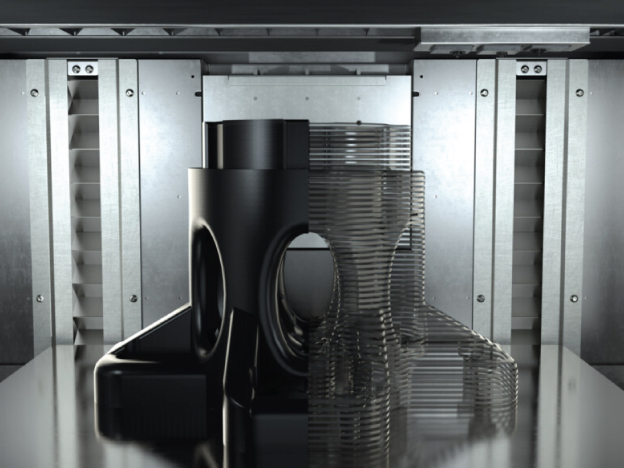

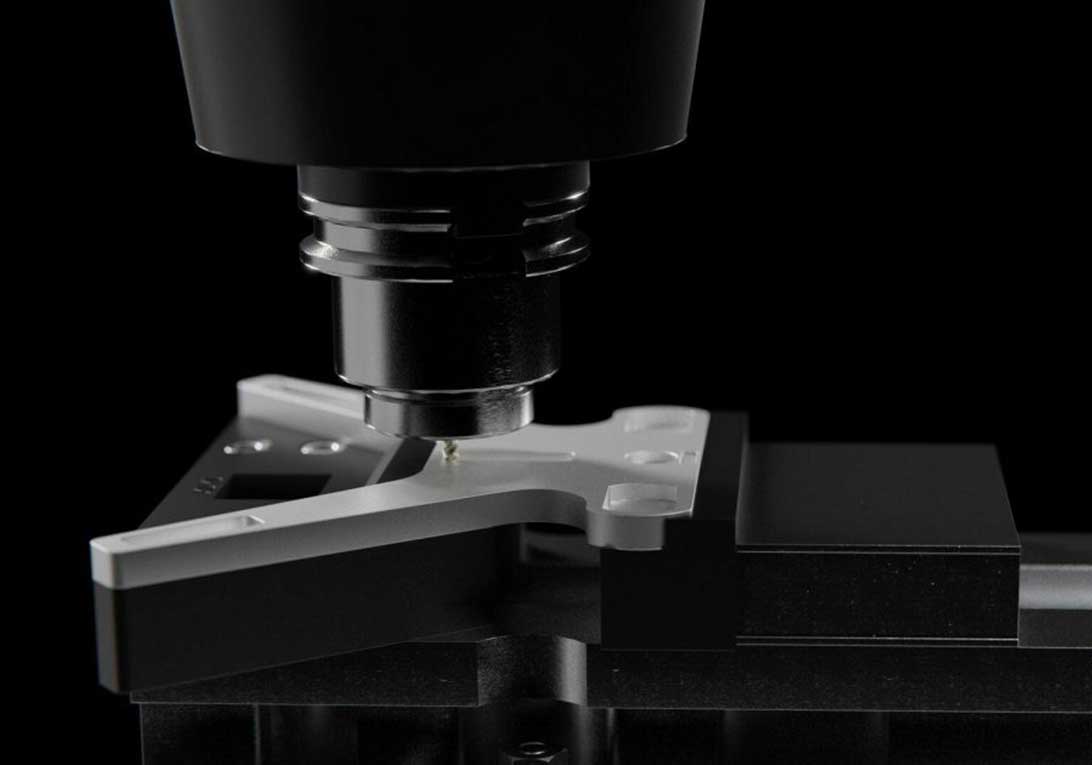

Carbon fiber meets Ultem filament

The FX20 is Markforged’s first machine capable of printing ULTEM™ 9085 Filament — an extremely durable thermoplastic that exhibits excellent flame smoke and toxicity (FST) resistant characteristics. When paired with continuous carbon fiber, you can print even stronger components, including high-strength, aerospace-grade composite parts.

Production-ready performance

The FX20 is a precise, sensor-driven machine that delivers breakthrough reliability with a simple user experience. Fully integrated storage and handling ensure materials stay dry for printing, while sensors monitor the performance of each part of the extrusion system. Linear encoders on the gantry and print bed provide precise, real-time feedback on the position of the print heads, resulting in highly accurate parts.

Advanced Material Cabinet:

An inboard material cabinet stores four XL (3200cc) spools with precise humidity controls. The new XL spools offer 4X the material, reducing the need for spool changeovers.

Three Nozzle Print Heads:

FX20 is capable of printing two polymers and fiber simultaneously — enabling support for ULTEM™ Filament material to be printed with ULTEM™ 9085 Filament and continuous fibers.

Large Touchscreen:

Connect to the Markforged Digital Forge platform through a 7-inch touchscreen. Start builds, monitor machine status, and perform maintenance all via one intuitive display.

Industrial Applications

What can I build on an FX20?

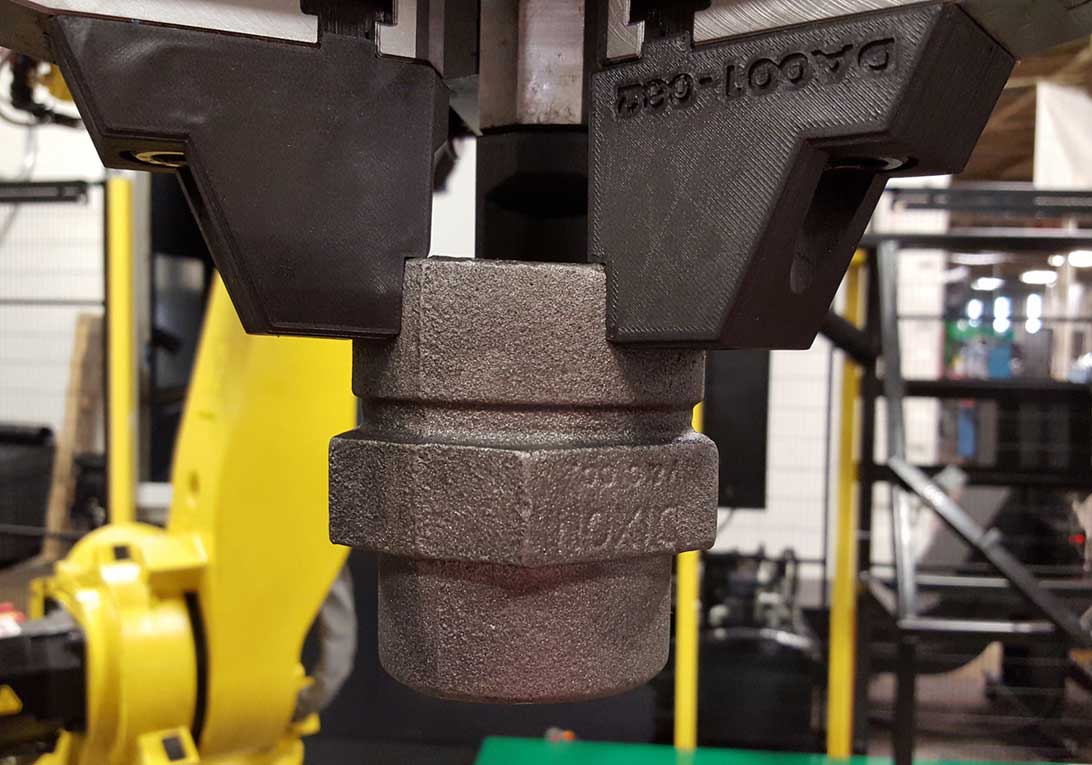

Build all your jigs, fixtures, and tooling in-house with 3D printing. From custom soft jaws for difficult machining operations to alignment jigs for welding, a Markforged 3D printer can improve many of the behind-the-scenes tasks associated with manufacturing and fabrication. Enhance your manufacturing floor with a Markforged printer and experience shorter lead times, increased machine bandwidth streamlined parts production and reduced manufacturing costs.

Watch Our 3D Printing Tour

Watch our On-Demand 3D Printing Germantown Technology center tour with a staff guide. These printers include metal, composite, and thermoplastic machines from Markforged 3D Printing.