In today’s rapidly evolving business landscape, manufacturing leaders constantly seek innovative ways to enhance their processes, increase efficiency, and stay ahead of the competition. One such innovation that has gained significant traction in recent years is 3D printing, also known as additive manufacturing.

Let’s explore how leaders of manufacturing companies are embracing 3D printing and implementing it into their manufacturing processes to drive innovation and achieve a competitive edge.

Investing in Research and Development

Leaders of manufacturing companies understand the importance of staying at the forefront of technological advancements. They recognize that 3D printing has the potential to revolutionize their industry and are willing to invest in research and development to explore its capabilities. By allocating resources to understanding the technology and its applications, these leaders can identify opportunities for incorporating 3D printing into their manufacturing processes.

Investing in R&D allows manufacturing leaders to gain hands-on experience with 3D printing equipment, materials, and software. They can collaborate with experts, conduct experiments, and conduct feasibility studies to understand how 3D printing can be integrated into their existing production lines or used to develop new product lines. This proactive approach enables them to harness the full potential of 3D printing technology.

Collaborating with Technology Partners

Manufacturing leaders recognize that successful implementation of 3D printing requires collaboration with technology partners and experts in the field. They seek partnerships with specialized 3D printing companies, research institutions, and industry experts to leverage their knowledge and experience. These partnerships help leaders understand the nuances of 3D printing, identify best practices, and navigate any challenges that may arise during implementation.

Collaboration also extends to the design phase, where leaders work closely with designers, engineers, and product development teams to optimize designs for 3D printing. By involving all stakeholders early in the process, manufacturing leaders ensure that the full potential of 3D printing is realized, resulting in more efficient and innovative designs.

Training and Upskilling Workforce

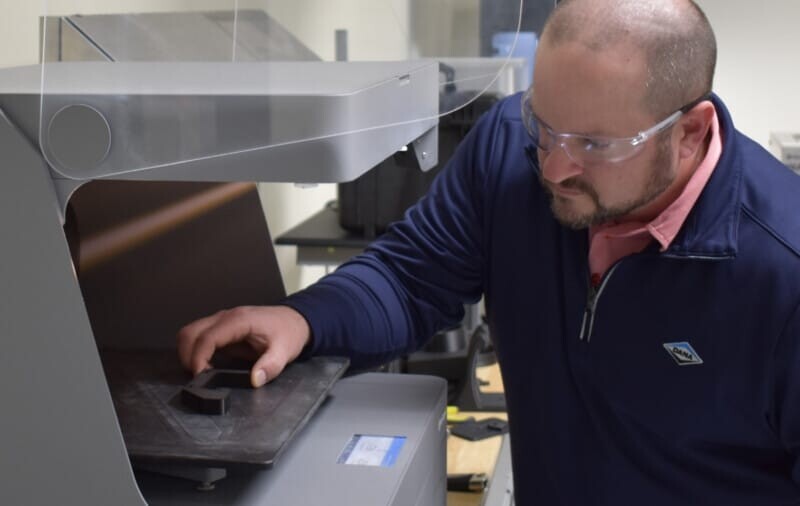

Leaders of manufacturing companies recognize that the successful integration of 3D printing requires a skilled workforce. They invest in training and upskilling their employees to ensure they have the knowledge and expertise to operate 3D printers, design for additive manufacturing, and work with the associated software and tools.

Training programs may include workshops, seminars, or specialized courses on 3D printing technology and its applications. By equipping their workforce with the necessary skills, leaders empower their employees to embrace technology and leverage it effectively in their day-to-day operations.

Pilot Projects and Proof of Concept

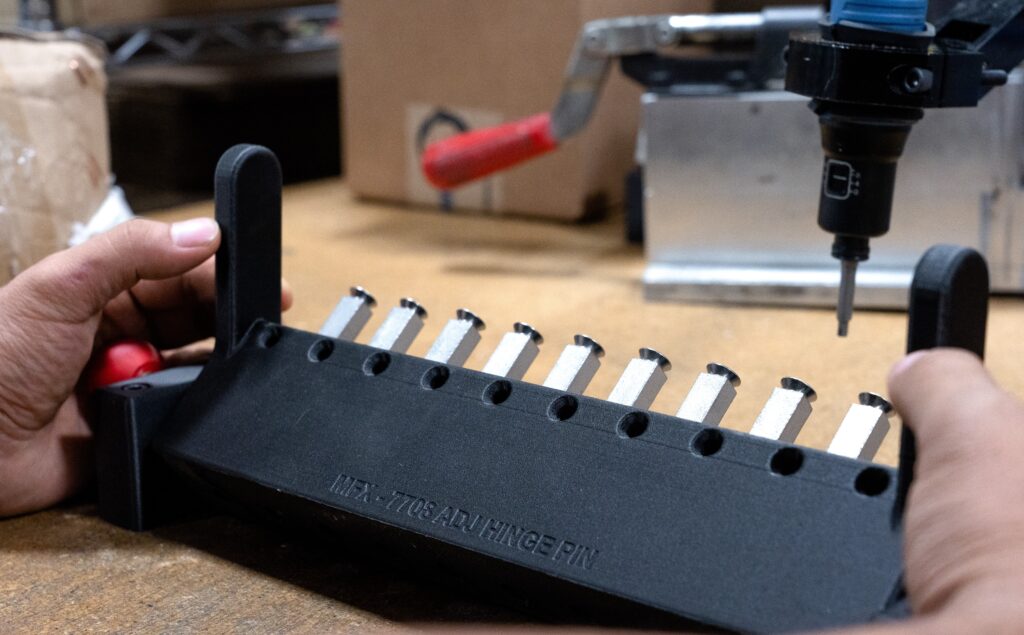

To assess the feasibility and potential benefits of integrating 3D printing into their manufacturing processes, leaders often initiate pilot projects and proof-of-concept studies. These projects allow them to evaluate the technology in a controlled environment, test its capabilities, and identify any challenges or limitations specific to their industry.

Pilot projects can involve producing prototypes, spare parts, or components using 3D printing technology. Leaders closely monitor these projects, analyzing the results and gathering feedback from stakeholders. This data-driven approach helps them make informed decisions about scaling up 3D printing capabilities and integrating them into their manufacturing strategy.

Integrating 3D Printing into the Value Chain

Manufacturing leaders go beyond utilizing 3D printing for prototyping or small-scale production. They strategically integrate 3D printing into their value chain, identifying key areas where the technology can create value and drive efficiency.

For example, leaders may implement 3D printing for on-demand production of spare parts, reducing lead times and eliminating the need for maintaining large inventories. They may also leverage 3D printing for tooling and fixture production, enabling rapid customization and reducing production downtime. By integrating 3D printing at critical points in their value chain, manufacturing leaders optimize their operations and gain a competitive advantage.

Continuous Improvement and Scalability

Leaders of manufacturing companies understand that innovation is an ongoing process. They continuously monitor and evaluate the performance of 3D printing within their manufacturing processes, identifying areas for improvement and scalability.

Through continuous improvement initiatives, leaders analyze data, seek feedback from employees and customers, and stay updated on advancements in 3D printing technology. They are proactive in adopting new materials, exploring new applications, and leveraging advancements in software and hardware to enhance their manufacturing capabilities.

Redefining the Industry with 3D Printing

Manufacturing leaders are at the forefront of embracing 3D printing technology to drive innovation and enhance their manufacturing processes. By investing in research and development, collaborating with technology partners, training their workforce, and conducting pilot projects, these leaders are paving the way for successful integration of 3D printing into their operations.

By strategically integrating 3D printing into their value chain and continuously seeking improvement, manufacturing leaders position themselves as pioneers in their industry. With their commitment to innovation and their willingness to embrace new technologies, these leaders are unlocking the full potential of 3D printing, driving efficiency, and achieving a competitive edge in the ever-evolving manufacturing landscape.

Contact Us

You’re passionate about your business. We’re passionate about fueling your success. Reach out today, and let’s start a conversation.

Get in touch with one of our 3D printing experts: 800-454-2233

Share

Meet the Author