The industrial equipment manufacturing industry is known for its multifaceted and involved production processes, often requiring specialized tools, extensive assembly, and high costs. However, 3D printing, a groundbreaking technology, has developed into a game-changing technology in this sector. Let’s explore the impact of 3D printing in industrial equipment manufacturing and how it is transforming the industry.

1. Streamlined Prototyping and Design

Historically, prototyping and design iterations have proved time-consuming and costly.

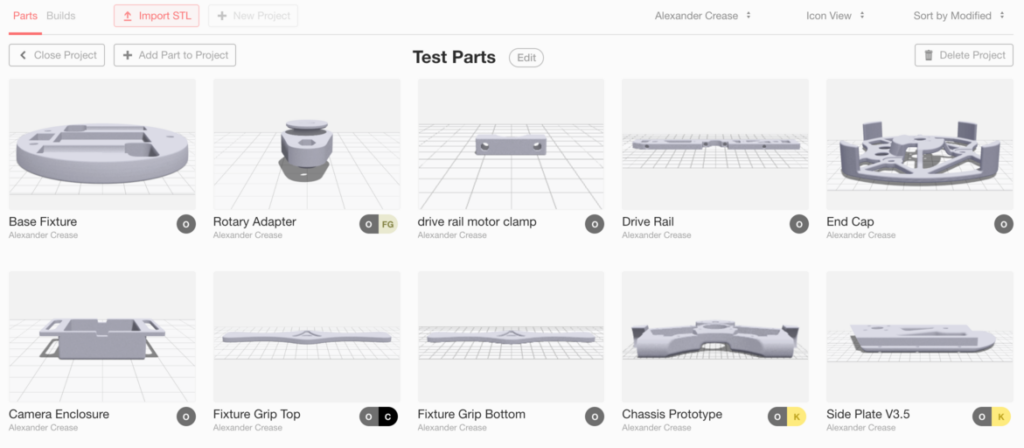

Manufacturers can now use 3D printing to produce detailed prototypes quickly, directly from designs allowing engineers to validate and refine their designs, leading to faster iterations and reduced development cycles. Manufacturers can deliver optimized and reliable equipment by detecting flaws early in the process.

2. Enhanced Customization and Complexity

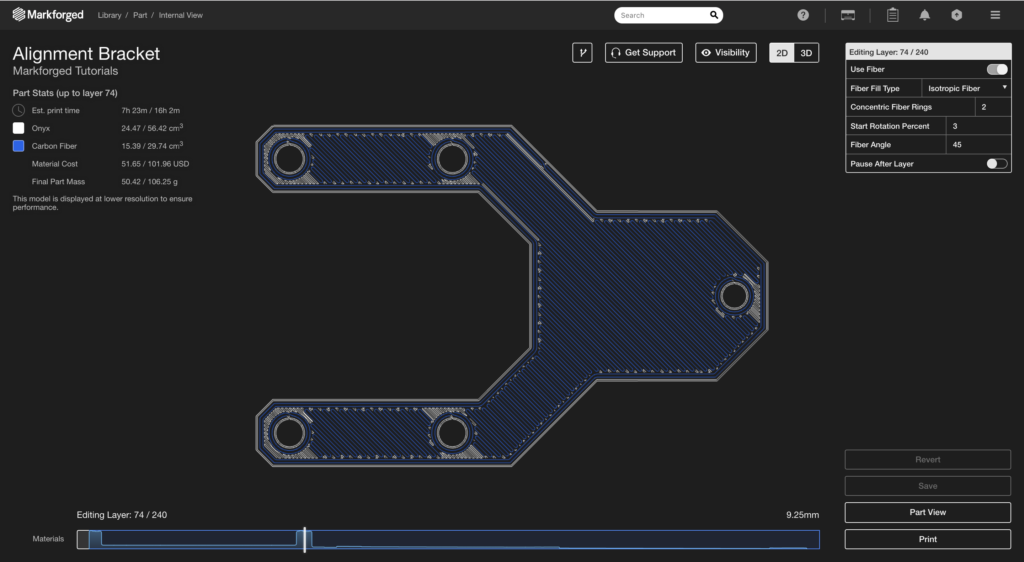

Industrial equipment often requires elaborate and complicated designs made to specific requirements. Offering customization capabilities that are difficult to achieve with traditional manufacturing methods, 3D printing technology also allows manufacturers to create complex geometries, channels, and lattice structures. All these capabilities lend to optimizing the performance and functionality of the equipment.

Manufacturers can also reduce the number of parts, simplify assembly processes, and eliminate compatibility issues by customizing components, resulting in more efficient and reliable equipment.

3. Improved Supply Chain and Spare Parts Management

When downtime can be costly, the availability of spare parts is critical, especially in the industrial equipment manufacturing industry. 3D printing has revolutionized supply chain management and side-stepped long lead times and risks by enabling on-demand production of spare parts.

By not relying on complex supply chains or holding large inventories, manufacturers can digitally store and reproduce spare parts with the touch of a button, oftentimes in hours or days, not weeks or months. It also ensures a more efficient maintenance and repair process.

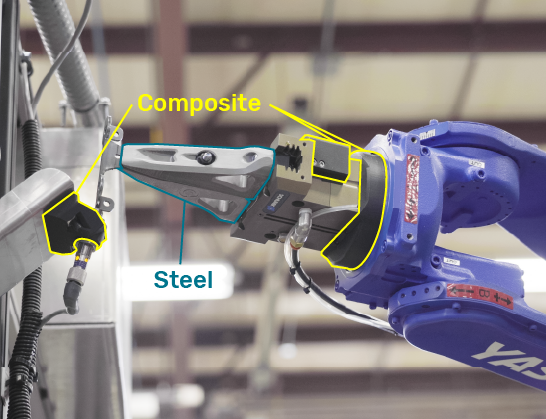

4. Lightweighting and Material Optimization

Industrial equipment specifications are oftentimes a double-edged sword, needing to be both robust and lightweight. 3D printing allows components to be designed with internal structures that maintain strength while reducing weight, allowing manufacturers to optimize material usage.

By printing with lightweight materials and complex geometries, manufacturers can produce strong and efficient equipment, enhancing performance. It also contributes to sustainability efforts by minimizing material waste and energy consumption during manufacturing and reducing equipment fatigue.

5. Cost Reduction and Time-to-Market Acceleration

High tooling costs and long lead times have been a pillar of traditional manufacturing methods and often hinder product development and time-to-market. 3D printing eliminates the need for tooling, molds, and specialized machinery, reducing upfront costs and accelerating production.

With rapid prototyping, design optimization, and streamlined manufacturing, 3D printing helps manufacturers bring innovative industrial equipment to market faster and more cost-effectively.

Adopting 3D Printing

The adoption of 3D printing in the industrial equipment manufacturing industry has sparked a tremendous shift in the manufacturing status quo. It’s offered streamlined prototyping, enhanced customization, improved supply chain management, and cost reduction. Users can anticipate further advancements and innovations with the technology as it evolves and matures, transforming how industrial equipment is designed, produced, and maintained.

3D printing, no longer considered new technology, is undeniably reshaping the landscape of industrial equipment manufacturing, paving the way for more efficient and sustainable solutions in various sectors.

Contact Us

You’re passionate about your business. We’re passionate about fueling your success. Reach out today, and let’s start a conversation.

Get in touch with one of our 3D printing experts: 800-454-2233

Share

Meet the Author