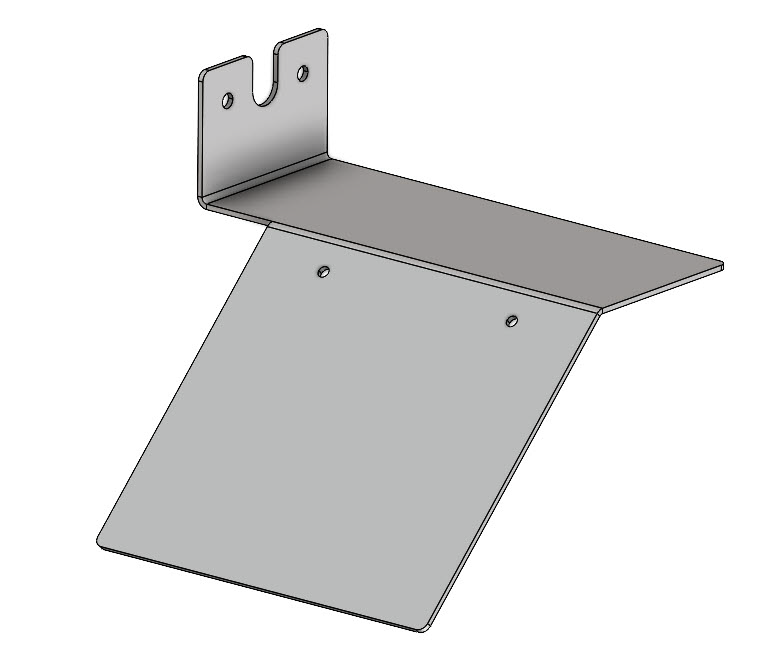

When most people think of sheet metal in SOLIDWORKS, they think of brackets, covers, and enclosures. These “traditional” sheet metal designs lend themselves well to a workflow based on sketching, making a base flange, and then pulling additional flanges from there.

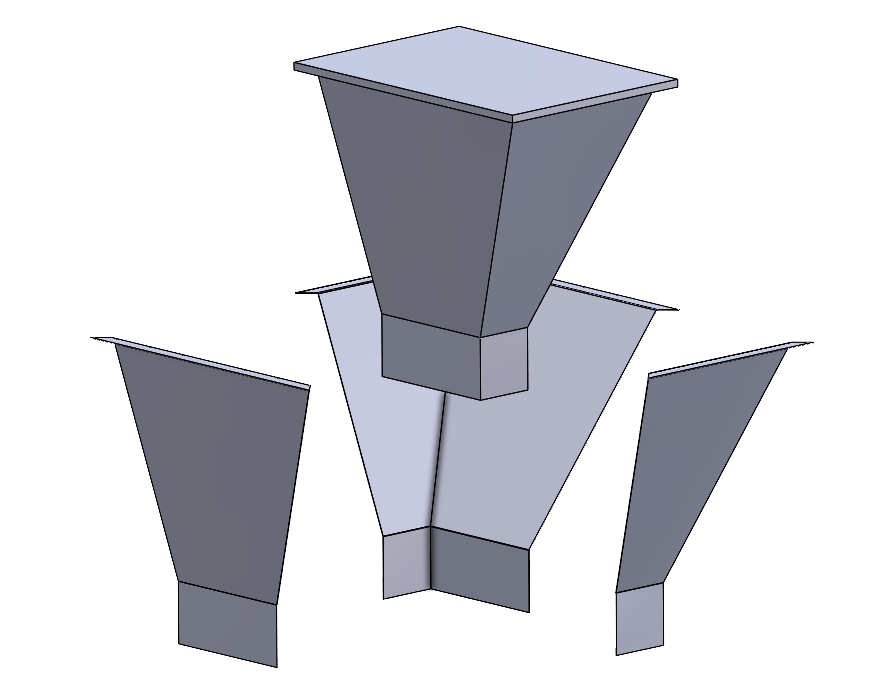

When looking at heavier sheet metal construction, such as chutes, hoppers, and similar designs where pieces are often welded together to create the final part, the “sketch-flange” workflow isn’t very efficient.

There is a much better workflow to create these kinds of designs, and they involve modeling the volume as a solid body and then pulling sheet metal pieces from the body. We even have a specific sheet metal tool called “Convert to Sheet Metal” specifically for this purpose – check out the video below to see how it’s done!

Contact Us

Have a question? We’re always available to talk over the phone at 262-790-1080; for you to leave a message or submit a request – contact us.

Want More?

Want to learn more tips and tricks with SOLIDWORKS? Check out the resources below::

Share

Meet the Author