All my friends know me as their go-to-girl if they ever need anything 3D printed. However, they also know my one rule: I won’t model up their project in CAD. This isn’t because I don’t want to help my friends bring their projects into reality, or because I don’t have time to model up their incredible idea for a reinvented mouse trap. Rather, it’s because up until a week ago, I *sucked* at SOLIDWORKS.

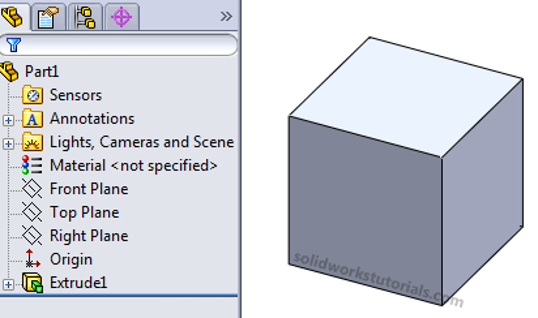

The extent of my ability was exemplified by this block:

I could sketch a square, and I could extrude it. And that was about it.

My SOLIDWORKS Transformation

Over the course of a week, GSC’s SOLIDWORKS Essentials training course transformed me from a SOLIDWORKS baby, to a functioning engineer. I learned everything from basic part construction – including chamfers, ribbing, and patterns – to rendering and the Hole Wizard. Other skills I picked up were creating assemblies, bill of materials, and drawings. We practiced each skill using comprehensive case studies and exercises designed to solidify each lesson.

One thing that GSC does a little differently from other training classes is that they also reserve a day for File Management. Typically not included in SOLIDWORKS Essentials, the file management course examined how engineers can work together on the same part without kerfuffling the file or workflow. If you’re like most people, and work with a team when designing parts, this is huge.

Fear Doesn’t Exist in This Dojo, Does it? No Sensei!

While the content of the SOLIDWORKS class is all well and good, I need to draw attention to true reason of my SOLIDWORKS educational success: John Setzer, the instructor. This man is a SOLIDWORKS god. He knows everything about SOLIDWORKS and was ultimately the key to my SOLIDWORKS comprehension. He kept class interesting with real world examples, engaging questions, and a touch of good humor.

There was more than one occasion when I was reminded of the movie, Karate Kid – John was Mr. Miagi and the class and myself were Daniel. I was never afraid to ask questions, and unlike Mr. Miagi, John answered my queries completely and without ambiguity.

Design Intention, Design Intention, Design Intention

A transferable concept stressed during training, design intention is my most important takeaway. In fact, if there is one reason to take the SOLIDWORKS Essentials training class, even as an engineer who is already somewhat proficient, this is it. Design intention is understanding how the foundational sketch or applied features of a part can change when subsequently edited. Using relations, symmetry, patterns, etc., design intention facilitates part construction in a logical manner.

You see, design intention forces engineers to develop precognitive workflows – that is, anticipating potential alterations and optimizing CAD construction to facilitate these changes. Constructing without these anticipations can lead to sloppy parts that take hours to edit, rather than minutes.

Nomadic CAD

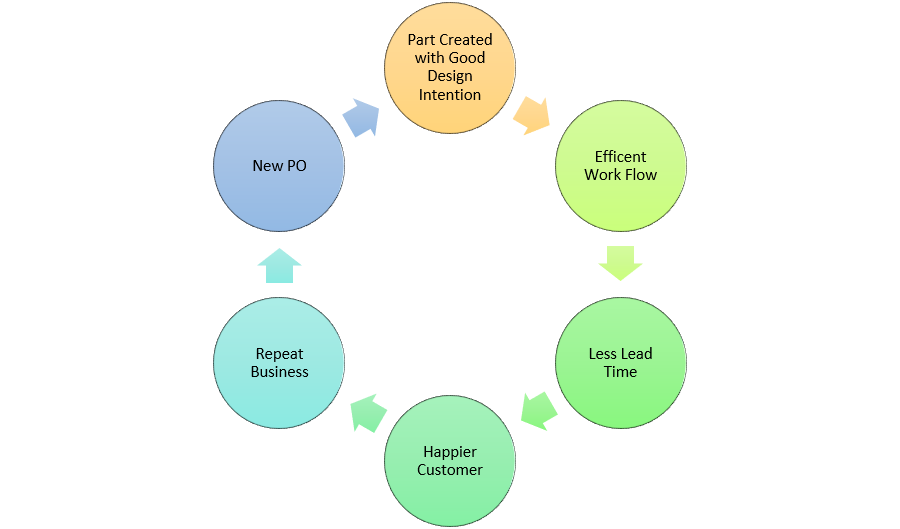

CAD is nomadic. It rarely lives on just one engineer’s computer; rather, CAD migrates to clients, engineers, and supervisors for review, feedback, and modifications. Given the communal nature of CAD, a haphazardly designed part can add excessive labor, time, and frustrations to all downstream. A part created with good design intention, however, can ease the work of any other person down the line. A fellow engineer can easily change the radius of every fillet at once for a new configuration, while a supervisor can quickly implement feedback during a customer meeting.

What does this mean in the bottom line? Take a look at the handy dandy flow chart.

Ultimately, good design intention makes everything better.

You Shall Not Pass (the HR Robot)

Pop quiz: Did you know that artificial intelligence (AI) is increasingly responsible for sorting good candidates from bad candidates for HR? According to the Wall Street Journal, AI is increasingly used as a gatekeeper, filtering resumes by things such as keywords and zip codes; this means qualified candidates’ resumes don’t always make it to a hiring manager. Most at risk to get knocked out in this robotic battle royale are recent college grads.

While difficult to get past this robot guard, there are a few things students can do to make them more attractive to a discerning AI: namely – you guessed it – training. Students that go to training can list the class attended and skills gained, adding critical keywords to their resume.

Once past the AI sentinel, a hiring manager will be more confident in a student with professional training, compared to other self-taught candidates. Professional training undoubtedly ups a recent college grad’s appeal to HR, while simultaneously awarding the student an opportunity to ‘test drive’ their future career.

Try Before You Buy

You wouldn’t buy a car before you drove it, so why purchase an undergraduate degree before you try any of the jobs it will afford you? Training gives students a chance to learn software and equipment on a deeper level than internships alone. Interns are rarely given more than a hasty tutorial on the software or equipment they’ll use daily. Because of this, interns usually develop a skewed opinion of the tools they’re likely to use in their career – a story all too familiar to myself.

At my first internship, my boss asked that I learn how to use the Faro Arm 3D scanner and its associated software. As there was no budget to send me to the week-long training, I spent a month figuring out how to collect a raw point cloud – something I would have learned in the first hours of training. The experience caused me to become disillusioned about scanning and soured my attitude towards a skill I would come to enjoy years later.

Had I initially gone to training, I could have bypassed all my frustrations and come to see scanning as a valuable tool sooner. On top of that, the wages I earned that month learning the scanner could have paid for the training course. I will say that independently learning the scanner was one of the most valuable things I’ve done and taught me a lot about learning on the fly, but looking back, it would have been both cheaper and more pleasant to send me to training rather than curse an inanimate object for a month.

Training: The Validation We Need to Succeed

Training also gives interns and employees peace of mind when performing their jobs. While I had successfully taught myself scanner operation, I was not confident in my skills. As the only person in the shop who could use the scanner, I became the unofficial metrologist. For a sophomore who’s self-taught, and has never had any validation that her workflow and technique is proper, this was absolutely terrifying. Having an expert validate my technique in an official training course would have allowed me to report part spec with confidence, rather than timidness.

Close Your Skills Gaps

Overall, attending SOLIDWORKS training forces people to step up their, uh, STEP files. All puns aside, developing talent is serious business.

I won’t bore you with regurgitating what the Financial Times Advisor or UNC Kenan-Flager Business School have to say about developing talent – such as how “over 70 percent of organizations cite ‘capability gaps’ as one of their top five organizational challenges,” or how companies such as Amazon or AT&T are focusing on “upskilling” their internal workforce – but I will mention that developing skills is crucial to any organization or student.

And, lucky for you, GSC has loads of training designed to help you do just that. From SOLIDWORKS Surfacing to DriveWorks Pro, see GSC’s full list of classes.

More on Maddie’s SOLIDWORKS Essentials Instructor

Contact Us

Have a question? We’re always available to talk over the phone at 262-790-1080, for you to leave a message or for you to submit a request – just contact us.

Share

Meet the Author