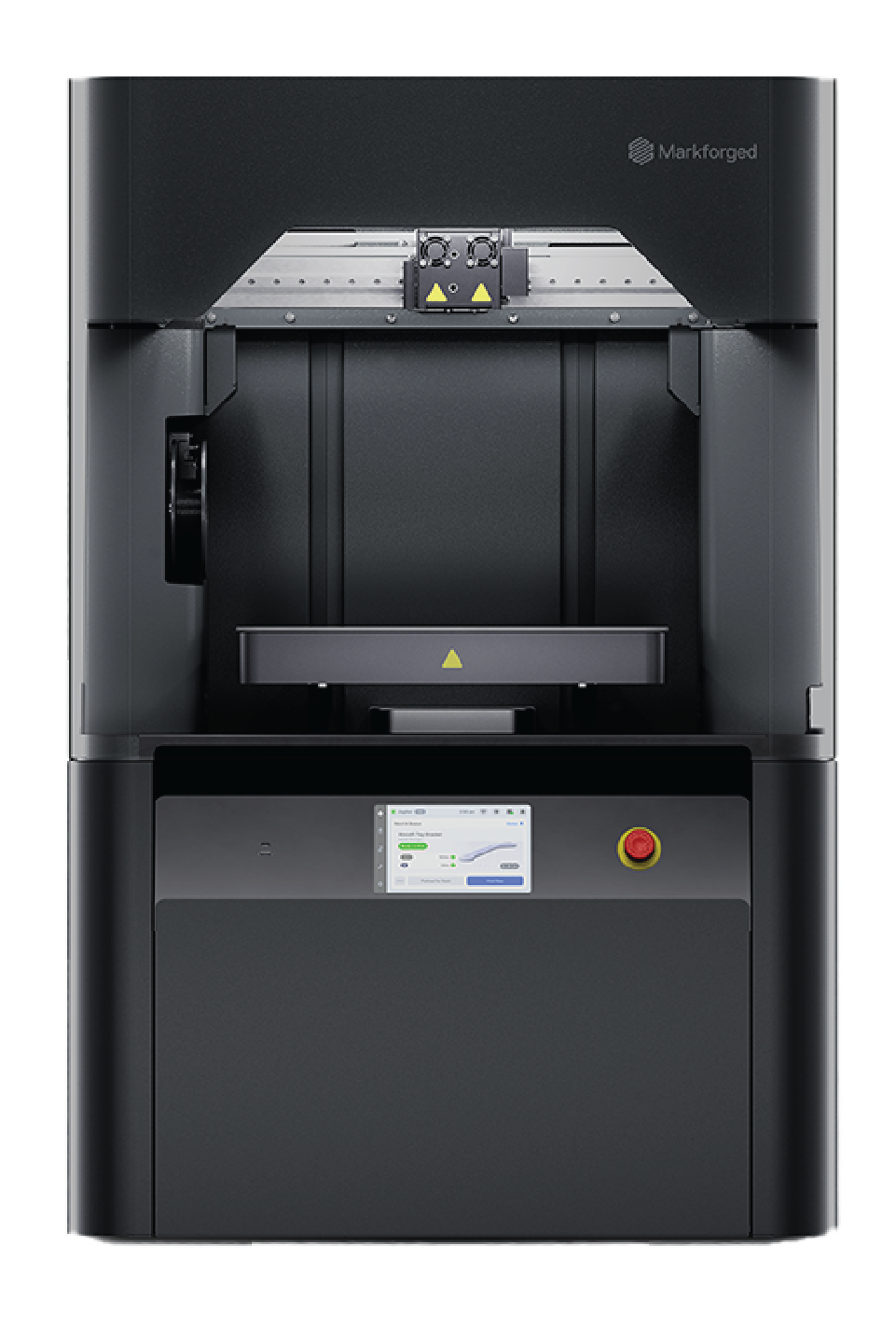

Markforged X7

The X7 3D prints continuous carbon fiber-reinforced parts in hours that can be as strong as machined aluminum. If you need to produce parts with excellent strength, flame resistance, chemical resistance, and energy absorbance, the X7 can fabricate functional parts for you.

The larger build volume, precision-built hardware, and laser-assisted leveling calibration of the X7 make it ideal for printing large functional end-use parts. Parts have an unmatched dimensional accuracy, surface finish, high strength, and temperature resistance.

Strong performing parts right off your machine

Markforged FX10

Markforged designed FX10 to deliver strong, accurate parts on every print — on an automated, factory-friendly platform that raises the bar for usability. FX10 prints continuous carbon fiber reinforced parts for a wide range of factory floor applications — helping manufacturers increase speed to market, slash fabrication and inventory costs, and de-risk line down events.

What Is Industrial 3D Printing?

Industrial 3D printing is the use of 3D printing technologies in a production environment to produce finished components. These additive manufacturing solutions lay down layers of high-grade plastics or carbon fiber to build complete components to tight tolerances. Depending on the raw materials, the tensile strength of finished components can exceed that of structural steel and aluminum. Industrial printers can print larger parts and have a high throughput. The 3D printing process is suitable for continuous production runs in industrial applications.

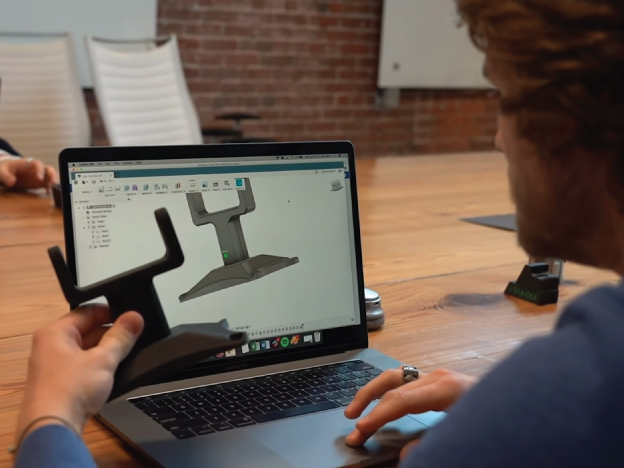

How Industrial 3D Printing Streamlines Design & Production

Industrial 3D printing is the use of 3D printing technologies in a production environment to produce finished components. These additive manufacturing solutions lay down layers of high-grade plastics or carbon fiber to build complete components to tight tolerances. Depending on the raw materials, the tensile strength of finished components can exceed that of structural steel and aluminum. Industrial printers can print larger parts and have a high throughput. The 3D printing process is suitable for continuous production runs in industrial applications.

Benefits of Industrial 3D Printing

- Less waste: 3D printing produces minimal waste compared to traditional manufacturing processes.

- No tooling costs: The parts are manufactured without tooling, potentially saving thousands of dollars in development and prototyping costs.

- Diverse printing materials: Multiple choices of printing filaments are available, from cheap plastics up to high-tech carbon fiber and even sintered metal components.

- Production costs: For short to medium production runs, 3D printing is often more affordable than injection molding and CNC machining processes.

- Improved manufacturing: 3D printing allows for specialists to support their manufacturing efforts by creating tooling and fixtures, adding further efficiency and benefit for everyone involved.

- Rapid prototyping: It's key to rapid prototyping used to quickly make function models and mockups of engineering designs

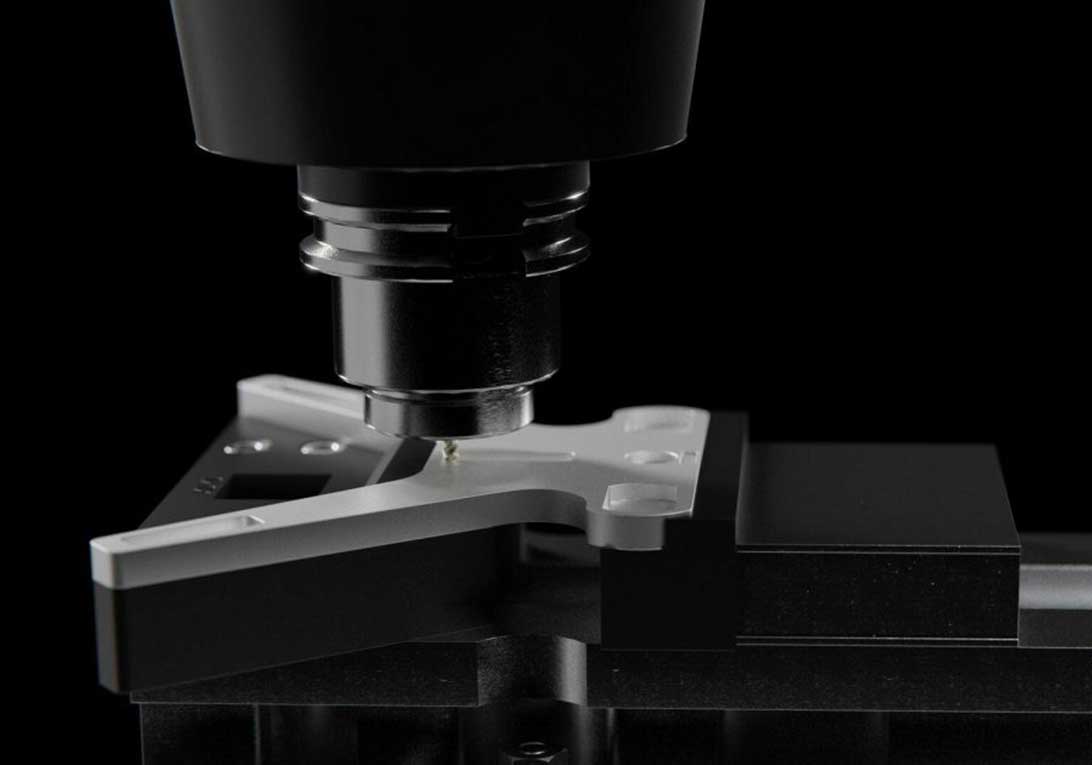

Bigger prints, high-quality surface finish

Markforged industrial-grade printers produce high-resolution and precise surface finishes for end-use parts. With a 50-micron resolution layer, your parts will resemble the look and feel of injection molding and come out of the printer ready to use.

Lower your costs

Visit the ROI Calculator to learn just how much Markforged could save you.

- Pick your Industry

- Choose a section in the Product Life Cycle

- Input a few parameters

- Receive an ROI Report with findings based on existing customers with similar applications

Inspect with Laser Precision & Advanced Sensor Technology

Software that brings it all together

Strengthen Your Parts

Continuous fiber fabrication

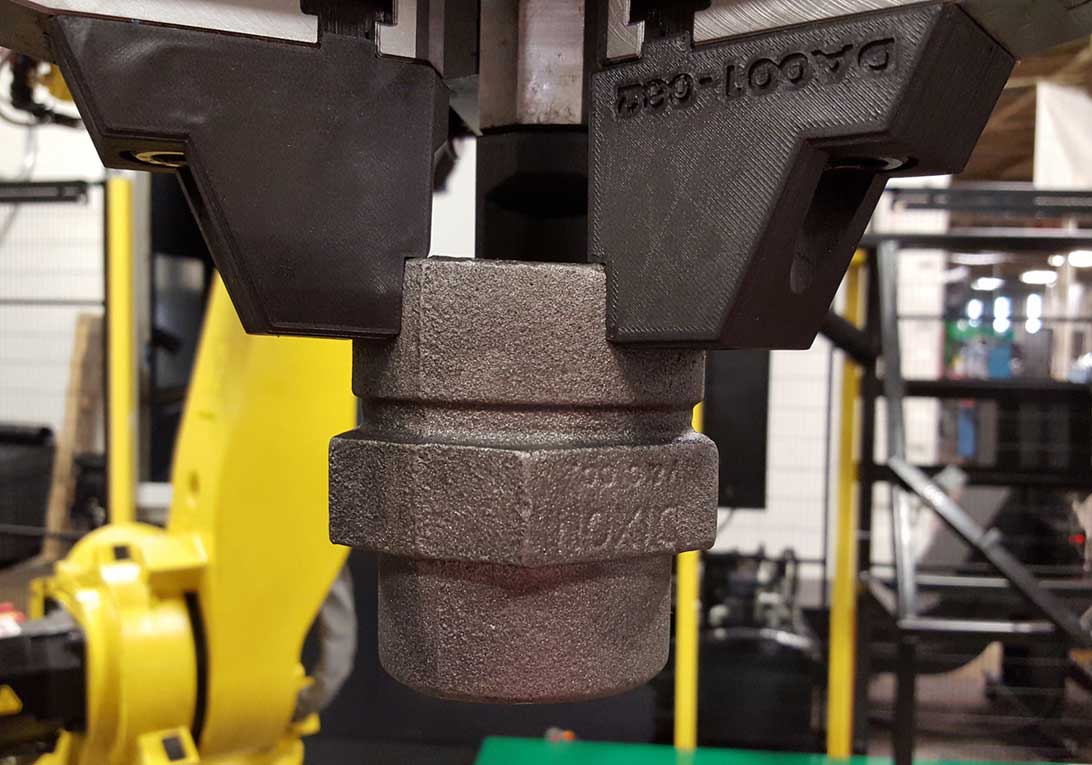

Dual print heads allow you to strengthen your parts with fiberglass, carbon fiber, Kevlar, or Markforged Onyx material.

Material usage detection

Printer estimates the amount of remaining material and alerts you when it’s low.

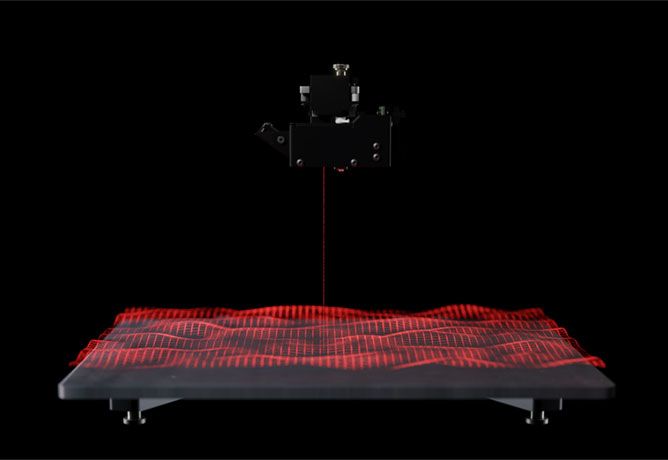

Active print calibration

Advanced laser sensor calibration scans the print bed and automatically levels it for more accurate builds.

Bed leveling

A properly leveled printer increases part accuracy and repeatability, improves print quality, and yields a high-quality surface finish.

Multiple print modes

Print with a wide range of materials and select from different print modes to achieve your desired surface finish.

Build Volume

Build your parts as large as 13 x 10.6 x 7.9 inches.

Industrial Applications

What Can I Build On An Industrial Printer?

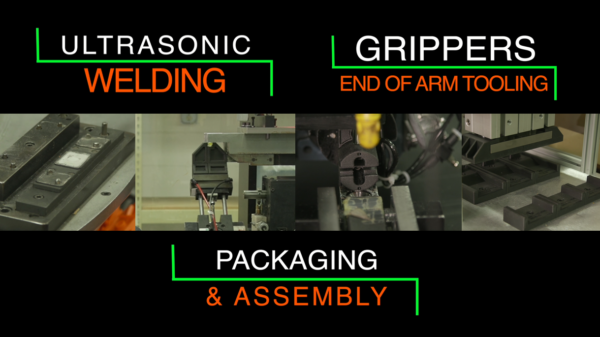

Build all your jigs, fixtures and tooling in-house with 3D printing. From custom soft jaws for difficult machining operations to alignment jigs for welding, a Markforged 3D printer can improve many of the behind-the-scenes tasks associated with manufacturing and fabrication. Enhance your manufacturing floor with a Markforged printer and experience shorter lead times, increased machine bandwidth, streamlined part production and reduced manufacturing costs.

Johnson Level purchased the Mark Two industrial grade printer and saw ROI within 9 months. New 3D parts make up their production line including an ultrasonic welding fixture, multiple grippers, packaging prototypes and a new assembly machine.

Watch Our 3D Printing Tour

Watch our On-Demand 3D Printing Germantown Technology center tour with a staff guide. These printers include metal, composite, and thermoplastic machines from Markforged 3D Printing