How do you keep the Coronavirus at bay when you serve the public and are running out of protective gear?

The Milwaukee Police Department was losing officers, fast. Any one officer that tested positive for the Coronavirus or showed symptoms needed to be quarantined for at least 2 weeks, as well as any officers who had been near them. Staffing and resources were depleting.

They needed a contingency plan.

Months Away from Safety

The Police Chief of Milwaukee put out a statement March 20th for businesses in the Milwaukee area to donate any Personal Protection Equipment (PPEs) they could due to supply shortages.

And it was that pressing need for more protective equipment, ensuring the safety of officers, their families, and the public, that was at the forefront of Detective Eric Draeger’s mind when he gave a call to a company down the road from his home. He’d heard they could do 3D printing.

Video: Watch Now & Hear The Story

Thank you to Detective Eric Draeger for sharing this story.

How Could 3D Printing Help?

The Milwaukee Police Department (MPD) needed to ensure they had enough respirator face mask filters to protect its officers and meet demand.

“When a cop is faced with going into one of these environments and being exposed, you’re not really worried about yourself. You’re worried about, ‘Did I catch this and am I going to be bringing this home to my kids and my family and maybe my elderly mom and dad?'”

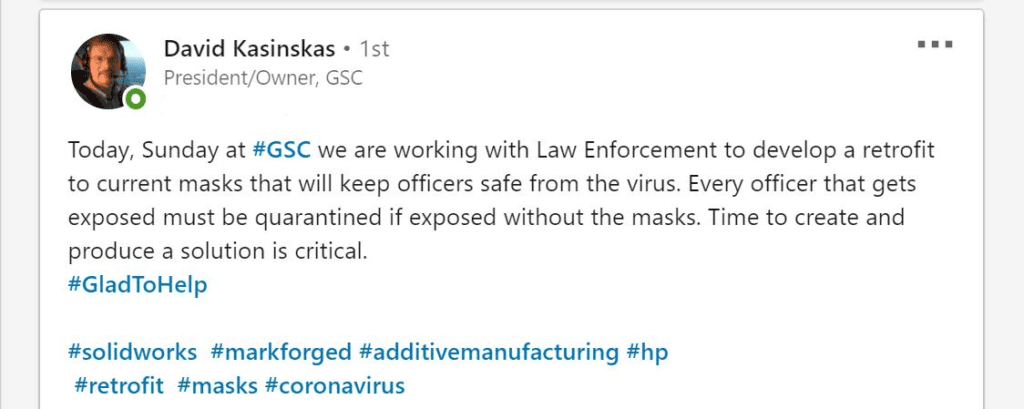

So Detective Draeger turned to GSC’s President Dave Kasinskas and our 3D printing team located in Germantown for help.

They needed to source new, HEPA-certified filters for their respirator face masks. They needed the right adapters to make the new filters work.

And to fill MPD’s need, they would need hundreds.

600, in fact.

It would take creative thinking to find filters that weren’t depleted in stores or online. And it would take designing and engineering new equipment to make the filters effective.

Their normal supply of filters is on back order.

Getting Creative with HEPA-Certified Vacuum Filters Donated by Milwaukee Tool & O-Ring Seal Caps Donated by Bradley Corp, Viking Masek

After our 3D Printing Engineers experimented with a vacuum filter from a store-run, they placed a call to Milwaukee Tool about a potential supply. Milwaukee Tool generously donated 600 filters the very next day.

Their filtration experts verified that the filters were HEPA (High Efficiency Particulate Air, or Arrestance) certified. The filters are manufactured, tested, certified, and labeled in accordance with HEPA filter standards (Abatement Technologies).

The design also required a protective seal when the filters weren’t in use. Bradley Corp generously donated 600 O-rings to complete the caps that seal the tops of these filters and quickly got them to our 3D printing team the next day.

We also received a fast response from Viking Masek with a donation of 600 O-rings. If any additional police departments require modification to their face masks, there are additional supplies available – please let us know your interest.

“I thought it was great how these teams from different companies came together during this kind of crisis. We had the protective equipment engineers from Milwaukee Tool. We had their 3D printing experts mashed up with the 3D printing experts here from GSC. We have all the right people in the room to be able to give us the best design,” said Draeger.

After sourcing the filters, GSC’s Aaron Niedermann quickly started prototyping an adapter for the filters, since they are a different size from the force’s normal supply.

This first involved reverse engineering the filter canisters in SOLIDWORKS and testing prototype parts on our HP 3D printers. Aaron had a working prototype within a few hours.

“We went from idea, to the design, to the actual field part in 5 and a half days. And that’s unheard of,” said Draeger. That is the beauty of 3D printing – the ability to quickly adapt and change as needed.

Aaron explained, “It was fast – it was a short print. It only took a few hours. And, we were able to double check all of our geometry before we continued on. We needed a large number of these, so it needed to be 3D printable at a very fast rate. And the less material, the better. So we used the HP 5200 3D printer.”

“We printed 125 to 250 adapter parts within a day, depending on how many runs we did,” said Aaron.

Watch below to see the design process at high-speed in SOLIDWORKS.

Reverse engineering the filter canister

Open Source 3D Printing Design Files

We have made the design files available. Please note that for law enforcement, these design files are specific to the issued mask the Milwaukee Police Department uses, and if you have the same mask you can use these files for easy adoption.

Dave Kasinskas, GSC President, and Jordan Kasinskas, 3D Printing Director, have been collaborating with the group from day one and are excited at the direction the project’s taken:

“The team collaboration on this was phenomenal with a high level of communication needed during the crisis. We saw a quick turnaround, from getting a call on Saturday night and a functional prototype by Monday,” said Dave.

Thermoplastic Material & HP’s Unique Jet Fusion Technology Ensured Protective Quality

Detective Draeger explained, “The question for us always is, how do we know this thing is gonna work in the first place? The guys on the street need to have confidence in this as well as the people at the top need to have confidence in a solution that’s engineered on site.”

Draeger continued, “I would put this product on right now and walk into a room with somebody who has the disease and be absolutely confident that I’m protected from it. I mean, my job as a detective is to be able to tell if something isn’t quite right. And I have absolute confidence in it.”

The Coronavirus particles are very small, making filtration a complex process and a major factor in the design process. The face mask includes a silicon lining for a great seal. GSC 3D printed the threads on the HP 5200 printer for a secure fit. There is an air-tight cap for storage.

All of these features are vital, because leakage can render the masks ineffective and expose officers.

Our 3D Printing Director has seen the success many area businesses have by pivoting to 3D printing in a pinch:

“This speaks to rapid design and rapid iterations. Essential businesses such as police forces need to protect their employees. The HP technology used on these face masks is air- and water-tight, and a better, more viable solution for the need,” he explained.

GSC produced 200-250 modified filtration masks that were available to officers in the last full week of March. As of April 7th, MPD has hundreds more available to them to fill their need and keep reserves stocked.

“We’re used to risking things, but that doesn’t mean we want to put those around us in a situation where they’re at-risk because of our decisions,” Draeger explained, “And having a solution in place takes that weight off your shoulders, when you know that you’re not putting them in danger.”

Keeping Public Health & Safety In-Mind

“This gives us a way to not only protect ourselves and our families, but also to stay in the fight. That gets right at the heart of what it is to be a police officer,” Draeger said.

He added, “Thank you to GSC and Milwaukee Tool for putting this together in such a short period of time. I know the officers in the Milwaukee Police Department also say thank you for this.”

Contact Us

At GSC, we strive to be more than just your technology provider. We work hard to become an extension of your team, always ready to assist when you need us the most. Since 1990, our technical experts have assisted companies like yours in implementing 3D tools for design, simulation, data management, electrical engineering, technical documentation, and 3D printing.

Let us show you why we’ve been recognized by SOLIDWORKS for top customer retention for 16 years in a row.

Share

Meet the Author