This September, we’re offering 7 free power hour sessions and 4 webinars all on Simulation. We cover introductory design analysis topics as well as in-depth application demonstrations from our customers’ experiences.

Whether structural, flow or fluid, plastics, material, or motion, we have an engaging and educational topic lined up for you.

Our goal is two-fold in Simulation Month. For newcomers to Simulation who want to learn more, we are providing the foundation to learn how Simulation works and can benefit you. For current software users, our goal is for you to quickly and easily perform Simulation techniques to optimize performance as you design, or fine-tune designs. Let’s learn more >>>

Sessions & Topics

Quick Table of Contents: Click on a power hour or webinar topic, and be taken to the section describing it below. Or, if you want to learn about our presenters, view our Sim Team Bios.

(Please note our Power Hours are filling up fast; if you are interested in one and it is full, keep your eye out for another date or let us know if you want to be kept on a waitlist)

- Product Validation

- O-Ring Simulation/Body Panel Seal

- Plastics Simulation

- Fluid Dynamics During Intubation

- Material Failure Fatigue Analysis

- Introduction to Abaqus

- Motion Analysis

- Structural Professional Engineer

- Topology Optimization

- Simulation for 3D Printing

For Beginners

Intro to Product Validation & Intro to Simulation

Wed., Sept. 9th, 2 pm: Come experience this quick start power hour training on Product Validation that will give you the tools necessary to get started validating your own products! SOLIDWORKS Simulation offers robust, easy to use FEA that can help you get a jump on better understanding your designs.

Tues., Sept. 15th, 2:30 pm: New to simulation? Come join us for this intro to SOLIDWORKS Simulation webinar to see how to efficiently evaluate the integrity of your designs while never leaving your CAD environment. This practical live demonstration will give you a first look into the workflow of how simulation can be used in your new product development process.

For Software Users or Intermediate Learners

Quick Start Plastics Training & Quick Start Structural Professional Engineer Training

Wed., Sept. 16th, 2 pm: Come experience this quick start Plastics training power hour that will give you the tools necessary to better understand the manufacturability of your injection molded parts. SOLIDWORKS Plastics offers robust, easy to use tools that will allow you to better understand all the different aspects of how your plastic part is molded and helps eliminate costly mold rework.

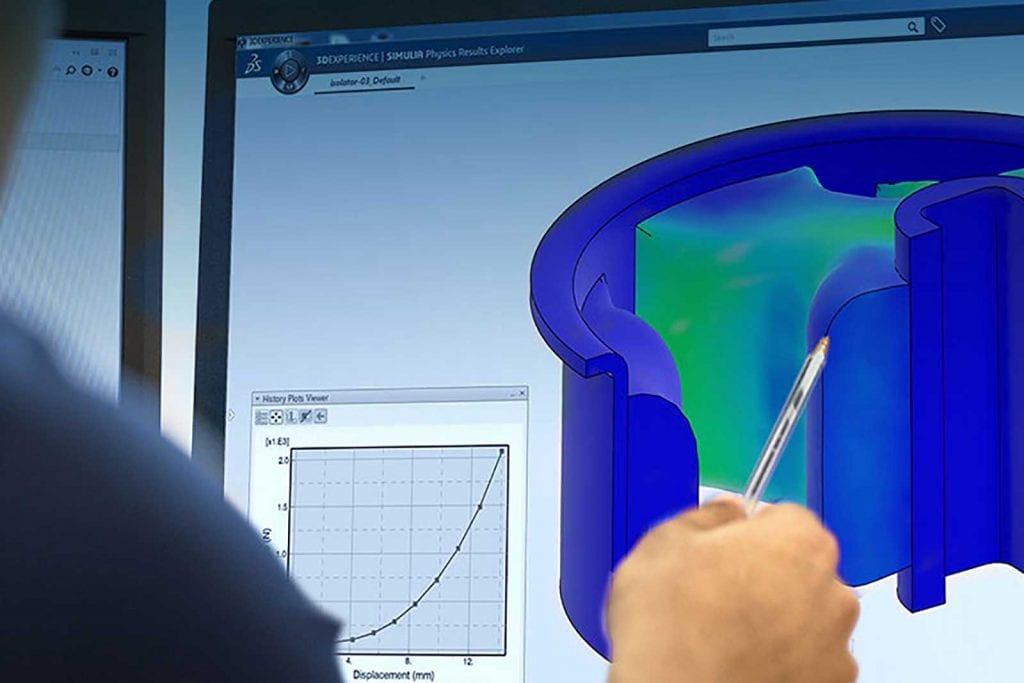

Mon., Sept. 28th, 2 pm: Get your feet wet with a quick start training power hour for Structural Professional Engineer, or SPE. A tool within the SIMULIAworks portfolio, SPE provides advanced simulation capabilities to analyze and test product designs faster.

Fatigue & Motion Analysis

Mon., Sept. 21st, 2 pm: Fatigue is an often-overlooked aspect of material failure. Come experience this quick start Fatigue Analysis power hour training that will give you the tools necessary to better understand how fatigue failure can be prevented in your designs.

Wed., Sept. 23rd, 2 pm: This power hour session on Motion Analysis will give anyone who owns SOLIDWORKS Premium or a simulation package an introduction to kinematic analysis using the motion tools available to them.

For Advanced Users, Specialized Topics

Body Panel Seal With O-Ring Simulation –

With SOLIDWORKS Simulation or SIMULIA Abaqus Solutions

Mon., Sept. 14th, 2 pm: Learn how our customer Fairchild Industries is approaching product design for a body panel seal using simulation tools during this power hour training titled Body Panel Seal with O-ring Simulation. Simulation tools demonstrated include SOLIDWORKS Simulation Professional.

Tues., Sept. 22nd, 1:15 pm: Streamline product development and accelerate virtual testing with structural simulation solutions using Abaqus. Attendees of this Abaqus Intro webinar will learn about the simulation of a body panel assembly with elastomeric seal subjected to impact using Abaqus standard solvers for the seal compression and Abaqus explicit solvers for impact.

Fluid Dynamics of Intubation, Topology Optimization, & Simulation for Additive Manufacturing

Thurs., Sept. 17th, 2:30 pm: Learn how SOLIDWORKS Flow Simulation helped evaluate and perform several design iterations of the development of an intubation chamber for medical personnel. This is our Fluid Dynamics During Intubation webinar.

Tues., Sept. 29th, 1:30 pm: Today’s consumer demands such as safety, durability, quality, comfort – to name a few – are influencing the products around us. Discover how innovative design exploration leads to virtual design testing and prototypes. In this webinar on Topology Optimization, we’ll take a look at real-life products and how they were optimized using simulation results.

Wed., Sept. 30th, 2 pm: In this power hour session on Simulation for Additive Manufacturing (or 3D Printing), attendees will learn the basics of performing an analysis on assemblies using multiple materials. However, in the specific case shown we will analyze a plastic composite reinforced with carbon fiber as it may be printed from a Markforged 3D Printer. Discussion of how to consider different material properties and behaviors will also be part of the session.

About the Presenters

Madhav Puppala

Madhav is Director of Simulation Products and Services. He has 25+ years of R&D engineering and innovation experience, expertise building global cross-functional teams, and problem solving. He specializes in design validation and failure analysis using SIMULIA, Abaqus, and SOLIDWORKS Simulation.

Chris Olson

Chris brings over 7+ years of experience to the table as a Simulation Applications Engineer. He’s certified on multiple SOLIDWORKS products including core SOLIDWORKS, Composer, and all Simulation packages. He’s participated in multiple FEA consulting projects. Chris is a graduate of University of Wisconsin-Milwaukee where he received his bachelor’s degree in Mechanical Engineering.

Brandon Donnelly

Brandon mentors customers as a Technical Account Specialist on how to apply simulation technologies to their design process. He has a graduate education in FEA Theory, Optimization, and Structural Dynamics and over 10+ years of experience in the engineering industry. Prior to GSC, he designed large span roofing components that were too large to prototype, relying on simulations to predict failure.

Contact Us

We’re always available over the phone at 262-790-1080, or, if you don’t have time for a phone call, we can take submitted inquiries online.

Want More?

If you’re interested in Simulation, here are more resources:

Share

Meet the Author