“Do you need to cut fuel consumption on a vehicle? Is a 4 part assembly getting too expensive to manufacture? Bring these concepts up. Hone in on a viable application and outline initial requirements like material properties, surface finish, or certifications.”

How does one go about developing new applications for additive manufacturing? It’s a question I get asked a lot, but the process of finding additive applications is unique and different for each company. With that said, there are a few general rules that can be applied to almost anyone.

Education

As Nancy Regan once said: “There’s a big, wonderful world out there for you. It belongs to you. It’s exciting and stimulating and rewarding. Don’t cheat yourselves out of this promise.”

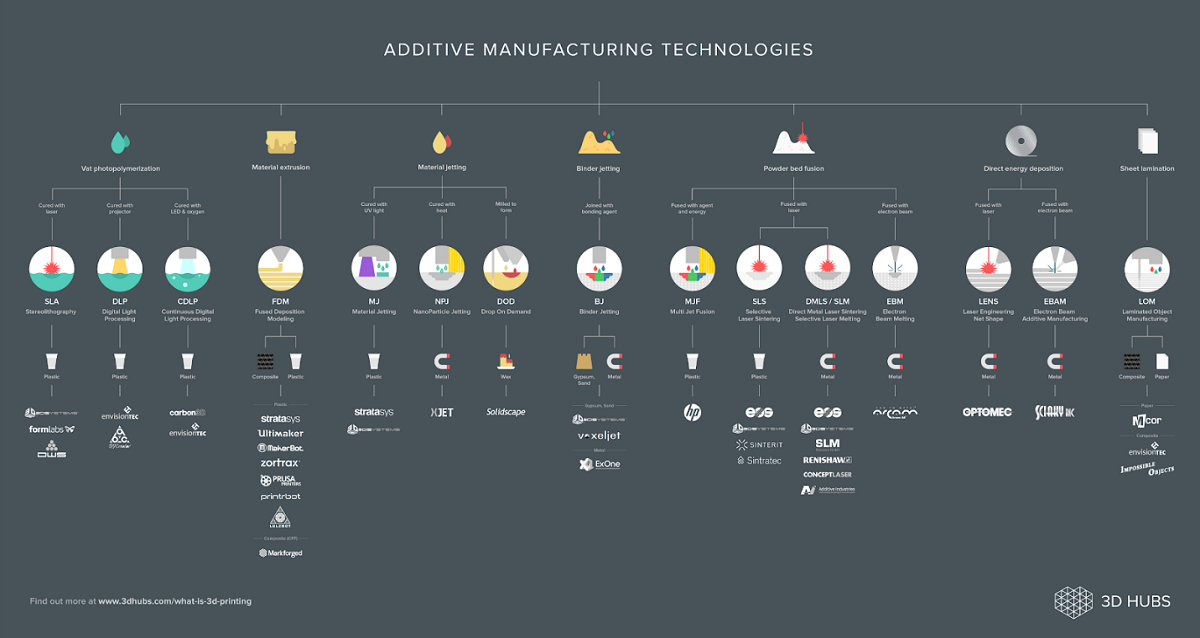

While Nancy was encouraging kids to live a drug-free lifestyle, I’m inspiring you to do your additive application homework. There is an infinite amount of exciting, stimulating, and rewarding ways to apply additive, but without proper education, you will cheat yourself out of this promise. Familiarize yourself with the berths of additive technologies. Take some time to page through case studies, read trade magazines, and talk to AM users.

If you can, get hands-on time with the machine and work as an operator for a week or two. With each bit of research, begin to paint a big, encompassing picture of the additive industry. Even if you think you know additive, there’s always something more to learn – so don’t skip this step. To get started, take a look at a few resources I’ve curated for you:

- TCT Magazine

- Metal AM / Additive Manufacturing News

- America Makes – National AM Innovation Institute

- Additive Manufacturing Magazine

Of course, this is only the tip of a very large iceberg, so explore beyond these few sites. Your additive knowledge will drive the development of your application. Knowledge decides your additive application, your timelines, your profits, and ultimately, your success. But just as a few days training won’t take a couch potato to Olympic gold, a few days of researching won’t take you from novice to additive master. To truly exploit additive’s potential, you’ll need an expert.

Bringing in the Big Guns

“Satair printed redesigned parts on a color 3D printer with astounding results: delivery time was cut from 40 days to 48 hours, lead times and part assemblies were halved, and part strength to weight ratio improved.”

An expert is someone who knows the additive industry inside and out. They have a broad knowledge of additive technologies, but typically specialize only in one or two. An additive expert will gleefully guide you through the harrowing – yet, worthwhile – additive application finding process. An expert will bring what I like to call the “Three Ns” to the table:

Nitro

An expert will take your team from zero to sixty faster than a souped up Subaru on nitro. While your innovative idea may never have been done before, chances are that an expert has transferable experiences that will speed along the process and shave months off of your development.

(K)nowledge

Okay, not really an ‘N’, but close enough. An expert knows their specialty machine better than they know their own spouse. Seriously. Through years of machines operation, experts pick up slick tricks that enable them to pristinely do what others consider impossible. Likewise, they know what absolutely cannot be done and will bluntly tell you.

Networks

Never underestimate the power of a good network. There are many advantages to having an encompassing network in this industry, from finding answers to tough questions to greasing wheels and getting things done faster. The additive industry is a small and tight knit group. Everyone wants to help each other with the common goal of widespread AM adoption, and if we can help a friend having trouble on a project, chances are we will.

Ideate

With your solid additive background, begin to brainstorm potential applications for 3D printing. Do you need to cut fuel consumption on a vehicle? Is a 4 part assembly getting too expensive to manufacture? Bring these concepts to your expert or your team, and be prepared to discuss them in detail. As you hone in on a viable application, outline initial requirements, like material properties; surface finish; or certifications. Together, you’ll find an application that will make use of all that additive has to offer.

Manage Expectations

Before embarking on this additive journey, make sure that you manage your teams’, and your own, expectations. There are many grandiose ideas surrounding AM – it can make anything, it’s an easy plug-and-play technology, it’s a panacea to any manufacturing pain point.

No.

Absolutely, NO.

These misconceptions are dangerous and can lead to impossible expectations. When these expectations are not met, AM becomes a charlatan technology, forever associated with fictitious promises. Like deer darting through roads in the dead of night, misconceptions are the problems you don’t see until it’s too late.

Ask yourself: Why are you using 3d printing in this work? What do you want to achieve by applying additive? What is the criteria for a successful application? Make a clear outline of these reasons and calibrate your goals and expectations to them. Share it with others so everyone is on the same page. A company which utilizes additive to shorten lead times, for example, will be satisfied if that goal is accomplished. Any other benefits are buttercream on an already tasty cake.

Leverage Additive’s Strengths

When developing an application, it’s important to leverage additive’s strengths. There’s a lot that additive can do well, like part consolidation, light weighting, advance geometry, customization, and low volume runs.

When properly wielded, additive will bring staggering returns to your business. A great example is Airbus subsidiary, Satair, who collaborated with both Chicago based additive service provider, Fast Radius, and HP 3D Printing to cut time on aircraft tool maintenance delivery. Satair, tapping into the expertise of Fast Radius and HP, printed redesigned parts in PA-12 on HP’s Jet Fusion 580 color printer with astounding results: delivery time was cut from 40 days to 48 hours, lead times and part assemblies were halved, and part strength to weight ratio improved.

Notice what Satair did to develop such a successful additive application – they brought in experts, they managed expectations, and they ideated an application suited for additive’s strengths. Notice a pattern here?

A Few Closing Thoughts

It may seem daunting, but incorporating additive manufacturing into your company can be incredibly rewarding when done right. Keep an open mind, and remember that GSC has plenty of knowledgeable staff to get you started finding the perfect additive application. Companies who don’t take the plunge today will be left behind as additive manufacturing becomes a standard like injection molding or CNC machining. Those who start today will have the knowledge to adequately serve their customers in the tomorrows to come.

Contact Us

Have a question? We’re always available to talk over the phone, for you to leave a message, or for you to submit a request – just contact us.

See similar blogs on 3D Printing:

Share

Meet the Author