We’re in Part 4 of our SOLIDWORKS Flow Simulation series! So far we’ve covered the basics and the stages. We’ve also covered what a basic mesh is, and an initial mesh. Now we’re going to talk about an adaptive mesh.

An adaptive mesh updates as the solution progresses. It has two reasons for existing:

- The form of the solution is unknown prior to solving.

- To calculate all iterations with a fine mesh can be a significant waste of time.

Situation #1 : The form of the solution is unknown prior to solving.

In areas of high pressure, temperature, or velocity gradients, it’s necessary to refine the mesh for higher accuracy. In some cases, intuition can predict where those areas may be but, in complex cases, it’s impossible to know in advance.

Predicting the size of the mesh necessary over small local regions of interest only becomes possible once the solution starts progressing. Allowing the software to choose the areas in need of refinement based on gradient values is an advantage because it skips the need to run many, many analyses iterating meshes along the way. You still should run a few meshes, but the software will do a lot of mesh heavy lifting for you with adaptive meshing.

Situation #2: To calculate all iterations with a fine mesh can be a significant waste of time.

The advantage of adaptive meshing is efficiency. Not much mesh is needed if the flow hasn’t “developed” yet. By using adaptive meshing, it’s possible to run the first few travels quickly while the flow develops. Then, when the mesh refines are much smaller, fewer iterations are needed to finish the solution. The net benefit is time.

Now that I’ve answered the why, let’s look at the settings:

The Dialogs For Adaptive Meshing

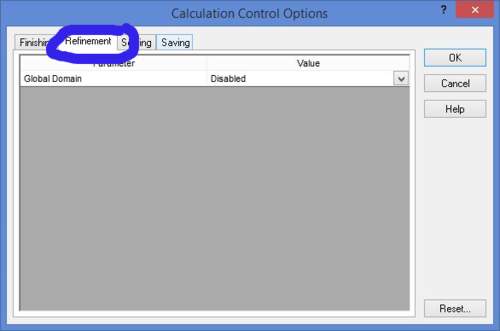

The image below shows the calculation control options dialog. It is under the refinement tab, seen circled here that adaptive mesh settings are controlled. In this dialog, the parameter “Global Domain” is set to “Disabled.” This means that no adaptive meshing will take place.

As you can probably guess, if there is a “Global Domain” parameter, there are also local parameters. If you have applied local mesh controls, then those to will show up here, giving you control over them individually.

Let’s take a look at what happens when we change from “Disabled.”

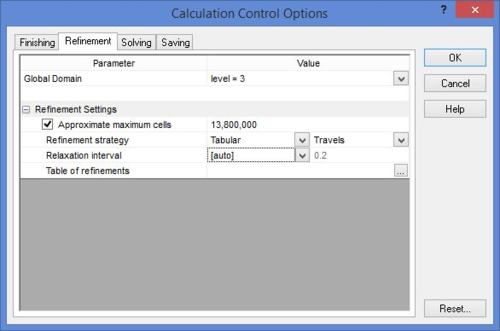

In the image above, you can see we have changed the “Global Domain” parameter, from “Disabled” to “level = 3”. This triggers the software to understand the entire mesh may be refined up to 3 times during the solution.

If you aren’t familiar with what is meant by 3 levels of refinement, I suggest you read Part 3 of this series for more information. The second image in Part 3, showing the multiple cube sizes and different colors, is what you’re seeking to achieve. There are choices that can be made in the finishing conditions that cause us to end the solution before all 3 refinements are made.

What the Refinement Settings Do

Approximate Maximum Cells Setting

Since the number of cells can quickly balloon (recall, in Part 3, that splitting a cell one level can create 8 cells in its place), this selection helps the software decide what the threshold should be. The approximation is about 1 million cells = 1 GB or RAM. If you don’t want to exceed your RAM and see a massive slow down, keep that in mind. Another good thing to remember is that Keep in mind also that just because you have 16GB of RAM, doesn’t mean that much is available for Flow Simulation. There are system processes and even SOLIDWORKS itself that are already using it.

Refinement Strategy Setting

There are three refinement strategies: Periodic, Tabular, and Manual. The selection of which way to do this is dependent on how much you know about your system and how much you want to babysit the software. Let me explain each of these:

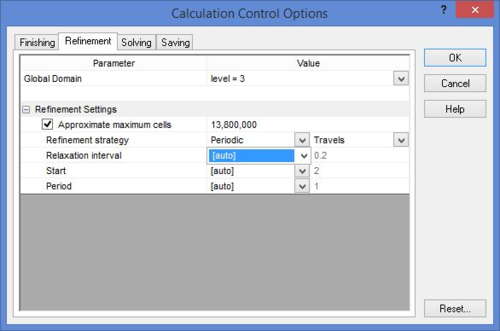

Periodic. For either the Periodic or Tabular refinement, you can choose to define by travels or iterations. The selection you make depends on what you want to achieve; however, travels tend to make more sense for several reasons which I won’t get into here. Just take my word for it.

There are a number of suboptions here:

- Relaxation Interval. This is the amount the solution must continue after the last mesh refinement takes place. If your values were already converged and the final mesh refinement took place, your solution would stop instantly after the mesh refinement. This ensures your calculation uses the last refinement to increase the resolution of the solution.

- Start. This is how far into the solution the first refinement will occur. Flows that take longer to develop should have a higher value here.

- Period. This is how often refinements happen. If the flows are highly non-linear and change drastically related to mesh changes, it may be necessary to put a larger number here. If the flows aren’t sensitive to mesh, then it can be a smaller value.

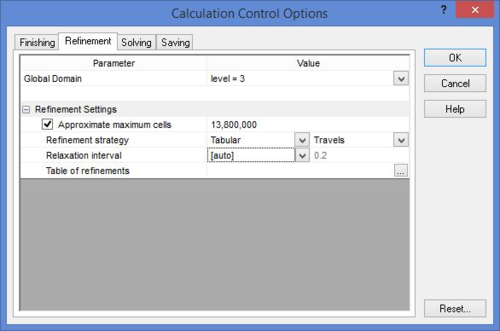

Tabular. As opposed to periodic, tabular is what you use to create refinements that don’t occur at even spacings. Generally, this is why it’s used more by more advanced users over periodic.

Manual. This is typically only used by the most advanced users when they aren’t sure how long it will take for a particular goal to reach a stable value. When it does, they typically perform the refinement and wait for it to stabilize again.

And, that concludes the series. I hope you’ve enjoyed reading all 4 parts of this series on SOLIDWORKS Flow Simulation and have gained some additional knowledge of meshing in flow simulation.

Share

Meet the Author