In California’s dynamic and competitive manufacturing landscape, innovation and efficiency are key to success. Manufacturers across the state constantly seek ways to streamline their design and production processes, reduce time-to-market, and stay ahead of the competition. For many, the answer lies in adopting advanced engineering software, such as SOLIDWORKS.

Let’s explore how California manufacturers can leverage SOLIDWORKS to remain competitive and thrive in their markets.

SOLIDWORKS: A Competitive Advantage

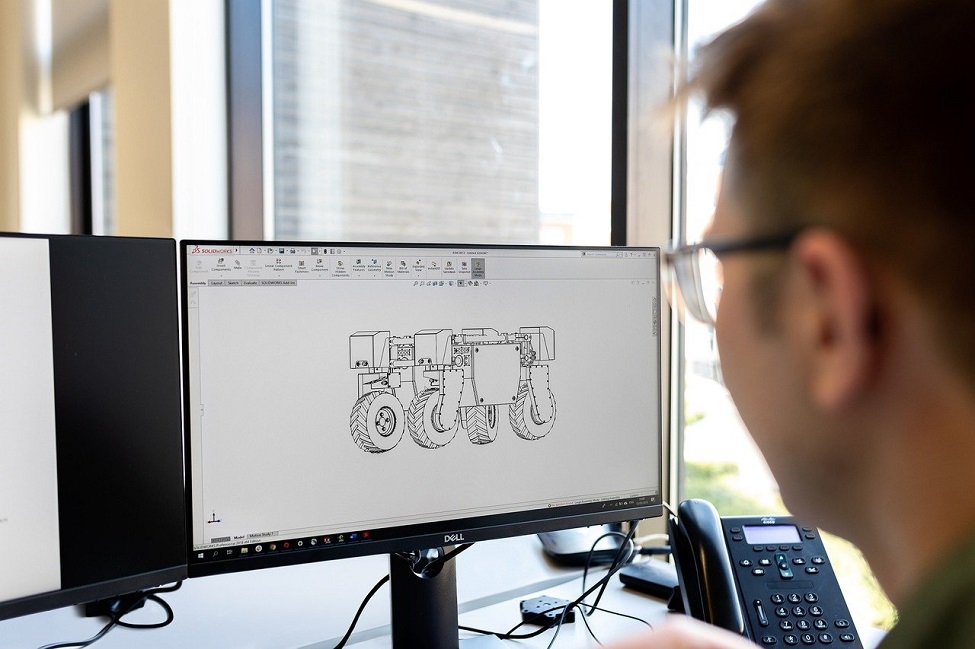

SOLIDWORKS is more than just CAD software; it’s a comprehensive suite of engineering tools that empowers manufacturers to bring their product ideas to life, improve quality, and drive innovation. Here’s how California manufacturers can stay competitive with SOLIDWORKS:

Streamlined Product Development

SOLIDWORKS provides a seamless and intuitive design environment that enables engineers to easily create 3D models, simulate real-world conditions, and generate detailed drawings. This accelerates product development, reduces errors, and allows quick iterations.

Enhanced Collaboration

With SOLIDWORKS, collaboration becomes more accessible. Teams can work on the same design simultaneously, whether they are in-house or distributed across different locations. This facilitates faster decision-making and minimizes communication bottlenecks.

Simulation and Testing

SOLIDWORKS offers advanced simulation capabilities, allowing manufacturers to test their designs virtually. This not only saves time and resources but also results in products that are better optimized for performance and durability.

Cost Reduction

By identifying potential issues and optimizing designs early in the development process, manufacturers can reduce material waste and manufacturing costs. This cost-efficiency is a crucial factor in staying competitive in the California market.

Customization and Innovation

California consumers often demand unique and innovative products. SOLIDWORKS enables manufacturers to customize and innovate their offerings efficiently, meeting consumer demands for personalization and cutting-edge design.

Integration with Manufacturing

SOLIDWORKS seamlessly integrates with various manufacturing processes. Manufacturers can create detailed assembly instructions and optimize production through its Manufacturing Resource Planning (MRP) features.

Success Stories from California Manufacturers

Several California-based manufacturers have successfully implemented SOLIDWORKS, reaping the benefits of enhanced competitiveness:

Tesla: The electric vehicle pioneer, headquartered in Palo Alto, uses SOLIDWORKS for the design of its groundbreaking electric cars. The software helps Tesla streamline design and manufacturing processes, contributing to its position as an industry leader.

SpaceX: The Hawthorne-based aerospace manufacturer uses SOLIDWORKS for designing rockets and spacecraft. The software assists in the rapid prototyping of components and supports the creation of complex structures.

Apple: The Cupertino-based tech giant employs SOLIDWORKS in its product development, allowing for the creation of sleek, cutting-edge consumer electronics.

California manufacturers operate in a fiercely competitive environment where innovation, efficiency, and high-quality products are paramount. SOLIDWORKS advanced engineering software empowers manufacturers to meet these demands head-on. By streamlining product development, facilitating collaboration, and enabling cost-effective design and testing, SOLIDWORKS positions California manufacturers for success. It’s not just software; it’s a competitive advantage that allows manufacturers to thrive and set new industry standards in the Golden State.

Learn how GSC is working with manufacturing companies in California here.

Share

Meet the Author