In food & beverage manufacturing, optimizing packaging lines is essential for meeting production demands, ensuring product quality, and staying competitive in the market. With the growing adoption of factory automation, improving throughput, optimizing line changeovers, and ensuring operator safety have become crucial priorities for industry leaders.

Fortunately, 3D printing technology from Markforged is empowering food and beverage manufacturers to achieve these goals and more, revolutionizing the way packaging lines are optimized and maintained.

On-Demand MRO Parts & Production Tooling

Food & beverage manufacturers rely on a wide range of machinery and equipment to keep their packaging lines running smoothly. However, maintaining these assets can be challenging, especially when OEM parts are no longer readily available, or lead times are too long. With Markforged’s 3D printing technology, manufacturers can produce on-demand maintenance, repair, and operations (MRO) parts quickly and cost-effectively. Whether it’s a custom conveyor belt guide, a specialized tool for adjusting packaging machinery, or a replacement component for aging equipment, Markforged’s Digital Forge provides a simple way to build custom parts in hours instead of days, minimizing downtime and maximizing operational efficiency.

Improved Throughput & Line Changeovers

In the fast-paced world of food & beverage manufacturing, every second counts. Optimizing throughput and minimizing line changeover times are essential for meeting production targets and maintaining profitability. Markforged’s 3D printing technology enables manufacturers to design and produce lightweight, durable tooling and fixtures that streamline production processes and reduce changeover times. From custom end-of-arm tooling for robotic pick-and-place systems to specialized jigs and fixtures for aligning packaging materials, Markforged’s Digital Forge helps manufacturers optimize packaging lines for maximum efficiency and productivity.

Enhanced Operator Safety

Safety is paramount in the food & beverage industry, where operators are often working in close proximity to heavy machinery and equipment. Markforged’s 3D printing technology enables manufacturers to design and produce lightweight, ergonomic components that improve operator safety without sacrificing performance. Whether it’s a protective guard for a packaging machine or a handle for a manual lifting device, Markforged’s Digital Forge allows manufacturers to customize components to meet the specific needs of their operators, reducing the risk of workplace injuries and ensuring compliance with safety regulations.

Examples of food & beverage manufacturing companies that are already utilizing 3D printing technology in their packaging process:

PepsiCo

PepsiCo, one of the world’s largest food and beverage companies, has been at the forefront of innovation in packaging technology. The company has been utilizing 3D printing to create custom packaging solutions for its products, ranging from beverage bottles to snack packaging. By leveraging 3D printing technology, PepsiCo has been able to design and produce packaging that is not only more aesthetically pleasing but also more functional and sustainable.

Nestlé

Nestlé, another global leader in the food and beverage industry, has been exploring the use of 3D printing technology to create customized packaging for its products. The company has been experimenting with various materials and printing techniques to produce packaging that is both attractive and eco-friendly. By utilizing 3D printing, Nestlé aims to reduce waste and improve the overall sustainability of its packaging process.

Hershey’s

Hershey’s, one of the largest chocolate manufacturers in the world, has also been embracing 3D printing technology in its packaging process. The company has been using 3D printing to create intricate molds and designs for its chocolate products, allowing for greater creativity and customization. By incorporating 3D printing into its packaging process, Hershey’s has been able to differentiate its products and appeal to a wider range of consumers.

Coca-Cola

Coca-Cola, a global leader in the beverage industry, has been exploring the use of 3D printing technology to create innovative packaging solutions for its products. The company has been experimenting with 3D-printed bottle caps, labels, and even entire bottles to enhance the consumer experience and reduce environmental impact. By harnessing the power of 3D printing, Coca-Cola aims to stay ahead of the curve and continue delivering innovative packaging solutions to its customers.

Key Food and Beverage Packaging Applications:

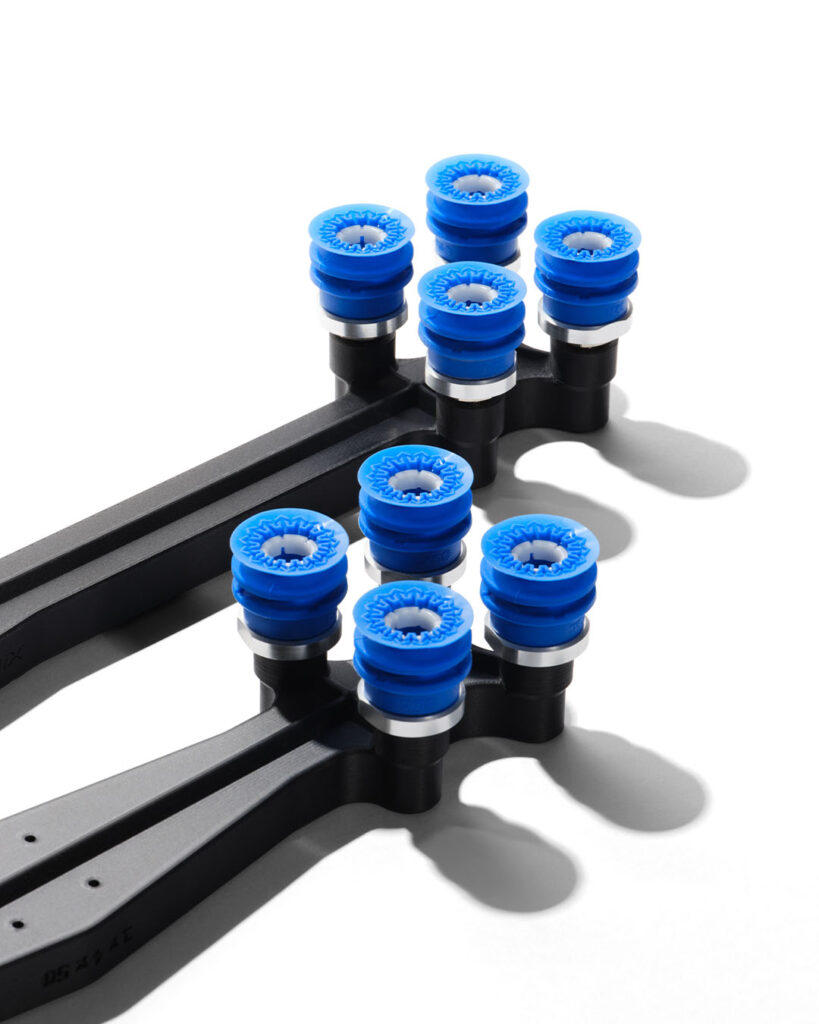

End of Arm Tooling:

- Vacuum Lifting Tools

- End effectors

- Bottle transfer tools/grippers

Safety Components:

- Machine guards

- Ergonomic tools/handles

Guiding Hardware:

- Pushers

- Paddles

- Bumpers

- Fixtures

General replacement parts:

- Clamps

- Brackets

- Belts

- Brake plates

- Rollers

- Gears

- Gauges

- O-ring

Markforged’s 3D printing technology is revolutionizing the way food & beverage manufacturers optimize packaging lines, enabling them to improve throughput, optimize line changeovers, and ensure operator safety. From PepsiCo to Nestlé, Hershey’s, and Coca-Cola, companies across the industry are leveraging 3D printing to create customized, sustainable, and innovative packaging solutions for their products. As 3D printing technology continues to evolve, we can expect to see even more groundbreaking innovations in food & beverage packaging in the years to come.

Share

Meet the Author