One of the most frustrating parts of the FEA world is a geometry won’t mesh, no matter what you do. What’s even more frustrating is when you don’t know what to do about it. I recently gave a presentation on the tools that can help troubleshoot a failing analysis, and I shared how the Geometry Analysis tool can be used to investigate areas of your geometry that may cause your mesher problems. It’s such a helpful tool, I wanted to share it with everyone!

Often times, the main cause of mesh failure is due to very small geometry within a model. In those situations, the size of the mesh just can’t fit an element into that space, thus the mesh fails. The trick is to determine where that troublesome geometry is located in your model, especially as the design becomes more and more intricate. The Geometry Analysis tool does just that.

The tool analyzes the model and locates the very small features within the model. Once we have located the potential trouble areas, the combination of adjusting the mesh size and cleaning the geometry will help fix our meshing problems.

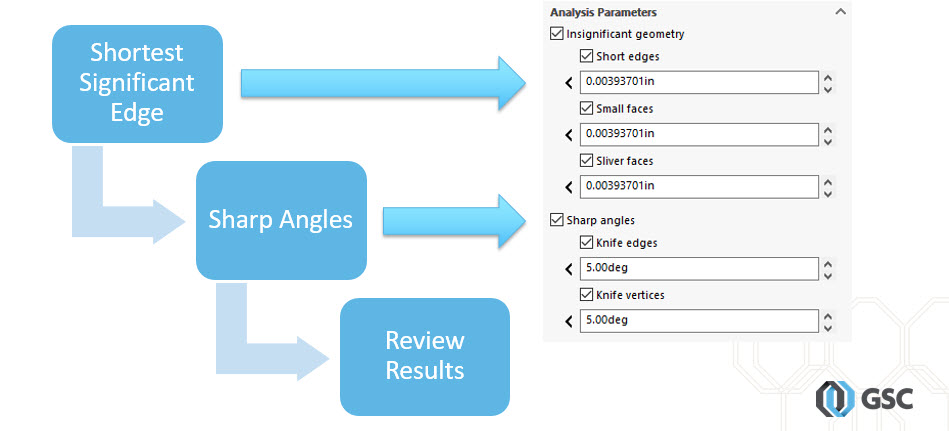

Geometry Analysis can be found under the Tools menu in SOLIDWORKS. It will ask you to specify a tolerance value for sharp angles and insignificant geometry.

In order to determine the insignificant geometry tolerance, think about the shortest significant edge in the model. This could be the edge of a fillet, wall thickness, hole size, etc. Take this size, divide it by 2, and use the result as your tolerance value. A default of five for sharp angles usually works well.

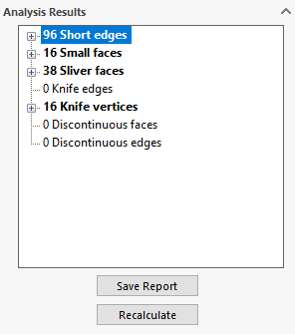

After the analysis, it will report all short edges, small faces, and sliver faces. You can expand the analysis to determine where each is located on the model.

Now that you know where they are located, you can either clean up the geometry for easier meshing in that area or try to apply mesh controls in those areas. Usually, that’s all you need to do successfully resolve a lot of your meshing problems!

Share

Meet the Author