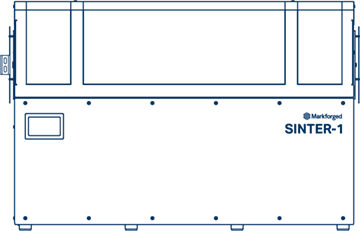

Metal X System

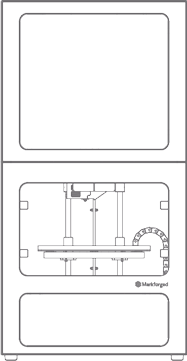

Metal X

Based on Markforged 4th generation composite 3D printing technology, the Metal X is a brand-new kind of 3D printer. By printing metal powder bound in a plastic matrix, we've eliminated the safety risks associated with traditional metal 3D printing while enabling new features like closed-cell infill for reduced part weight and cost.

Inconel 625 Filament

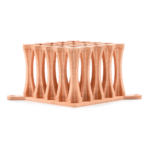

Copper Filament

17-4 PH Stainless Steel

H13 Tool Steel

A2 Tool Steel

D2 Tool Steel

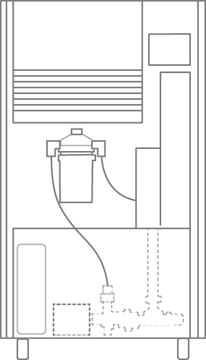

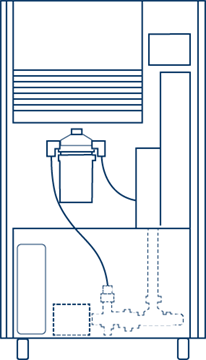

Wash-1

The Wash-1 immerses the green part in a specialized fluid, which removes the primary binding material and leaves the part semi-porous so the remaining binder can easily burn off during sintering. The Eiger software automatically calculates this debinding step and purifies the final metal part keeping your sintering furnace clean.

Atomic Diffusion Additive Manufacturing:

A Whole New Way to Build Metal Parts in as Few as 28 hours

Upload the STL and select from a wide range of metals. The Eiger software does the rest making printing the right part easy.

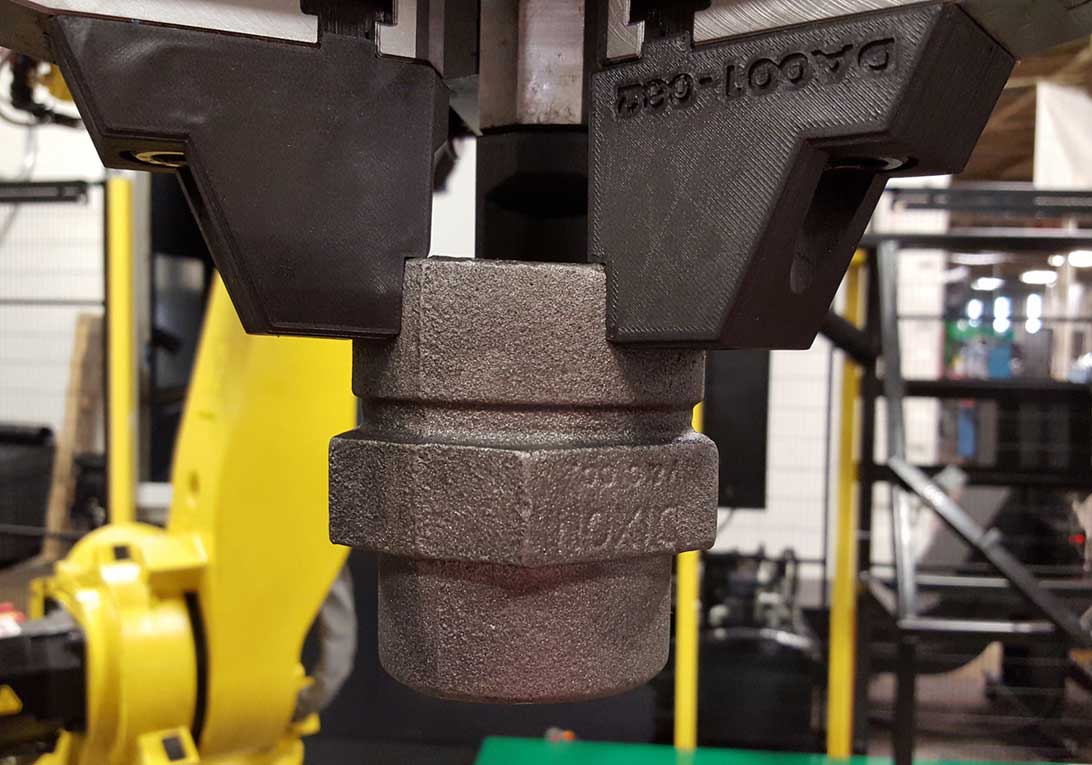

Metal powder bound in plastic is printed a layer at a time into the shape of your part. Parts are scaled up to compensate for shrinkage during the sintering process.

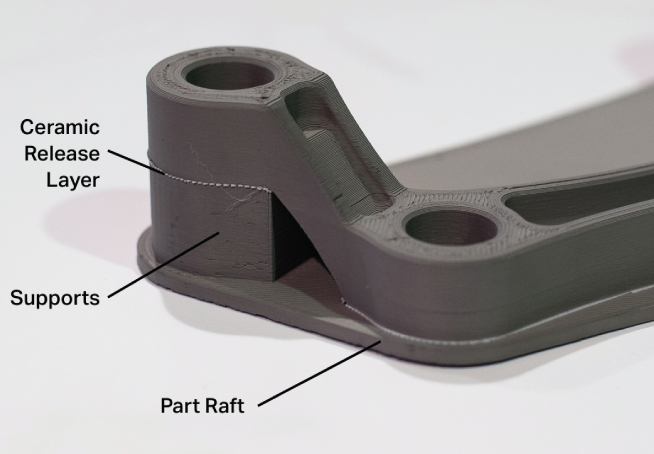

A green part is fragile and has not been washed or sintered. The raft and support layer ensure that the part shrinks properly for your desired part.

Wash time is automatically calculated by Eiger. The printed “green” part is placed into the solvent to remove more of the polymer and binder.

Printed parts go through a washing stage to remove some of the binder. They are then sintered in a furnace, and the metal powder fuses into solid metal.

Finished part is ready for end-use

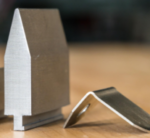

Part Scaling

The Eiger Software automatically scales parts to compensate for shrinkage that occurs during the sintering process.

1

Designed part is uploaded and automatically oversized to account for shrinkage in the part. Eiger automatically scales the part by approximately 20%.

2

The part is printed using two materials a bound metal powder filament and a ceramic release material. After the part is printed, it is a "green part" and is placed into the wash.

3

Washed part is sintered, turning your part into metal which is the same size as the CAD design file.

Industrial Metal X Applications

Unlock new possibilities with Metal X 3D printing

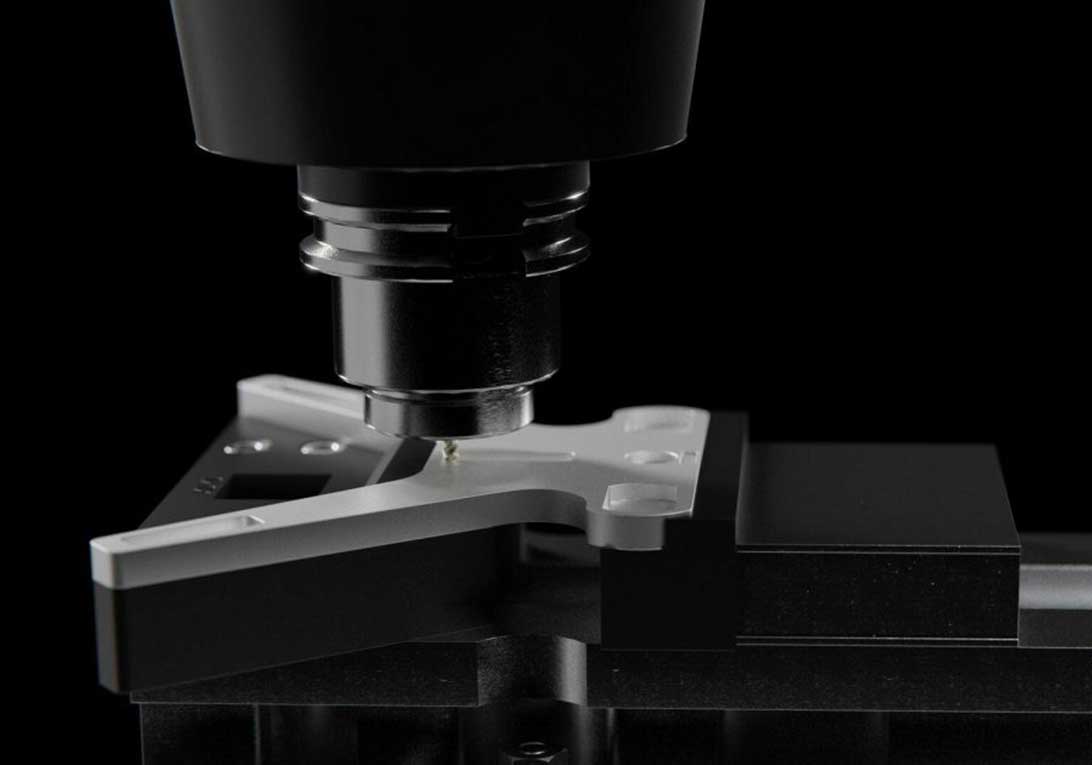

While metal 3D printing is not replacing traditional manufacturing methods, it changes how we think about fabricating metal parts. Building a part additively instead of subtractively brings distinct advantages.

3D printing offers more geometric freedom, requires no tooling, and fabricates parts using a completely automated workflow. By leveraging these applications, you can 3D print parts in metal faster and more affordably than you could fabricate them any other way.

Watch Our 3D Printing Tour

Watch our On-Demand 3D Printing Germantown Technology center tour with a staff guide. These printers include metal, composite, and thermoplastic machines from Markforged 3D Printing.