When a company grows, its use of and need for simulation tools requires more inputs and balancing of more constraints. As a consultant, I’ve worked on in-depth projects and trained hundreds of different companies on Finite Element Analysis and Computational Fluid Dynamics, managing the adoption of a more data-driven decision-making structure is critical. To break it down further, understanding the goal of each stage and how to get there is equally as important because of many commonly overlooked aspects.

This short guide will help you move down the “rungs” of the decision-making structure, starting with the fundamentals and moving to the more complex.

Provisions for Data-Driven Decision Making

Having a clear business value of analysis is one frequently overlooked aspect of moving to a data-driven structure. Often, some of the following items are needed for an easier transition.

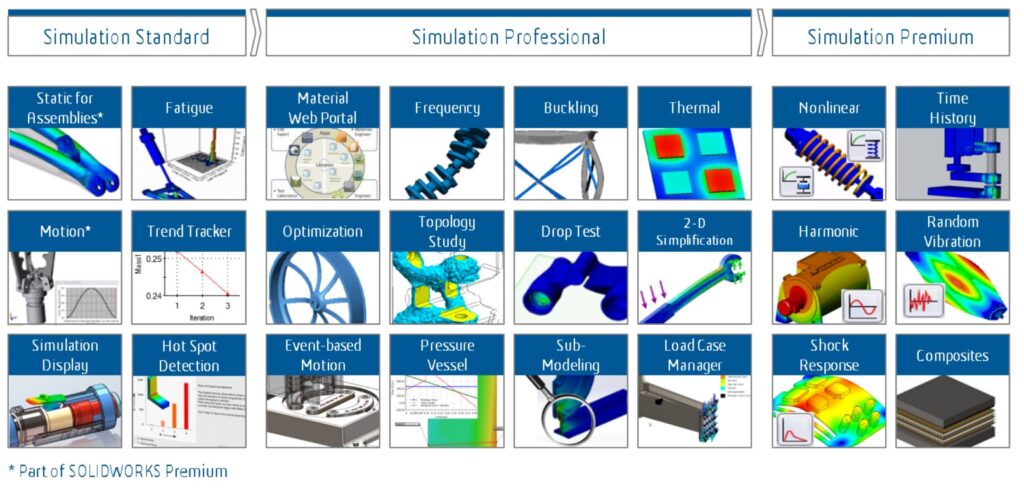

- Pick a source of data: Lab, equations, software (SOLIDWORKS Simulation, SOLIDWORKS Flow Simulation, SOLIDWORKS Plastics, 3D Experience Structural Mechanics Engineer are examples)

- Explore hiring options to bring an expert onboard. A degreed person may be necessary.

- Use consultants and solutions providers, like GSC, to learn as much as you can about the space. Visit the GSC Simulation page to learn about the tools and software that may help you.

For deeper learning, check out these resources: Benefits of Virtual Simulation over Hand Calculations, SAS Forks Success Story, GFI Eliminates Field Failures

Data-Driven to Single-Parameter Optimization

A common oversight in this process can be the documenting of optimization criteria for future results as well as making sure all parties are aligned. The below tips can help circumvent these issues.

- Establish optimization criteria: Weight, cost, factors of safety, etc.

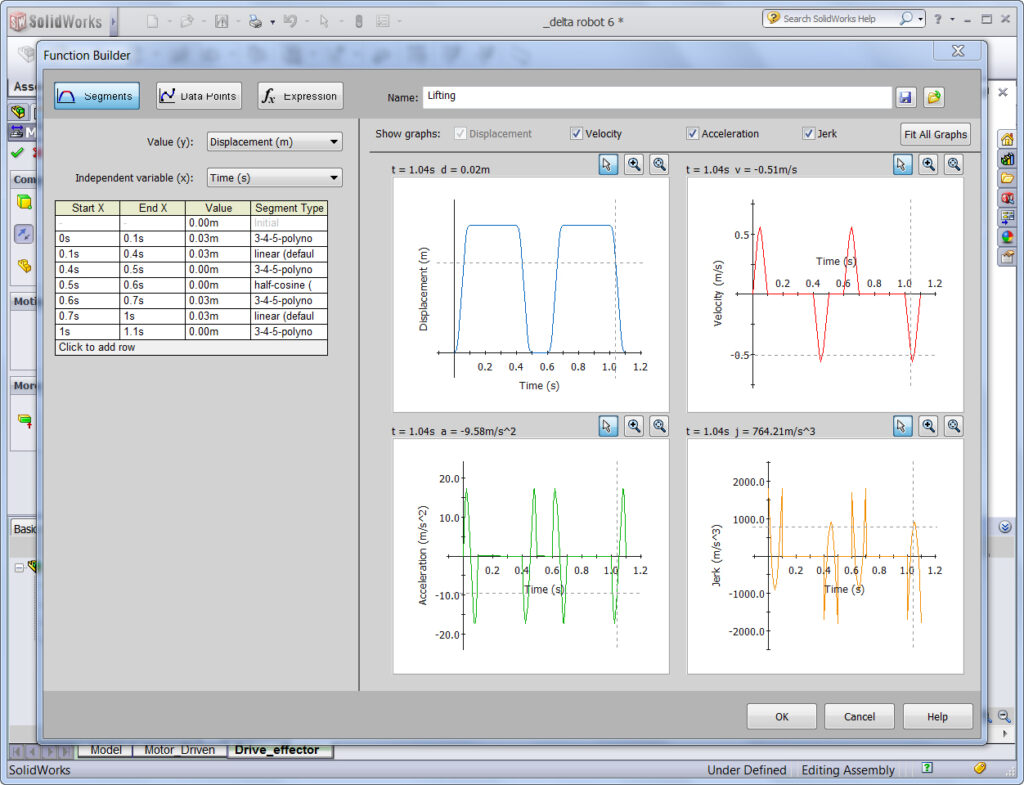

- Provide tools or systems to efficiently perform optimization.

- Build accurate material models.

- Ensure the person doing this work is well-trained and proficient in the tools. At this stage the tools will be running several analyses to optimize the criteria, so inefficiencies will be multiplied many times over.

For deeper learning, take a look at these resources: Topology Optimization and Advanced Simulation, Free Surface Flow at GE Healthcare, Using Flow Simulation for Intubation

Single-Parameter Optimization to Multi-parameter Optimization

Understanding how, who, and what tradeoffs will be evaluated is an easy-to-miss component of the process. Applying these tips can help in the vetting process.

- Additional software or tools may be necessary if you are optimizing across domains. If you were previously optimizing the structural design of a hairdryer housing but are now also optimizing the flow of air from the fan, you have linked aerodynamics and structural problems based on the housing design. You may need two different tools like SOLIDWORKS Simulation and SOLIDWORKS Flow Simulation for this scenario.

- The person performing the Single-Parameter Optimization work may or may not have the competencies suitable for this work alone when the new parameters added to the optimization could be in the same domain or a different one.

- Continuous development of material libraries is critical.

- Communication and best practices for how to weigh “tradeoffs” will be necessary.

For a deeper look, watch this video on a brake rotor redesign.

Multi-Parameter Optimization and the Next Level of Complexity

- As you enter the most complex stage, bring in a solutions provider like GSC to have an initial conversation about applicable goals and the direction of the organization.

- Craft a plan with your solutions provider, like GSC that contains software tools, training plans, and consulting needs for implementation.

- Decide on the benefits in conjunction with the reseller. If they are substantial enough, set a timeline up.

With the wrong partner, implementing a data-driven decision-making system might be intimidating. Regardless of the assignment’s complexity, GSC will assist you at every stage. For additional information, including webinars, events, and instructional resources, visit gsc-3d.com.

Contact Us

Have a question? We’re always available to talk over the phone at 800-454-2233, leave a message, or for you to submit a request – just contact us.

Share

Meet the Author