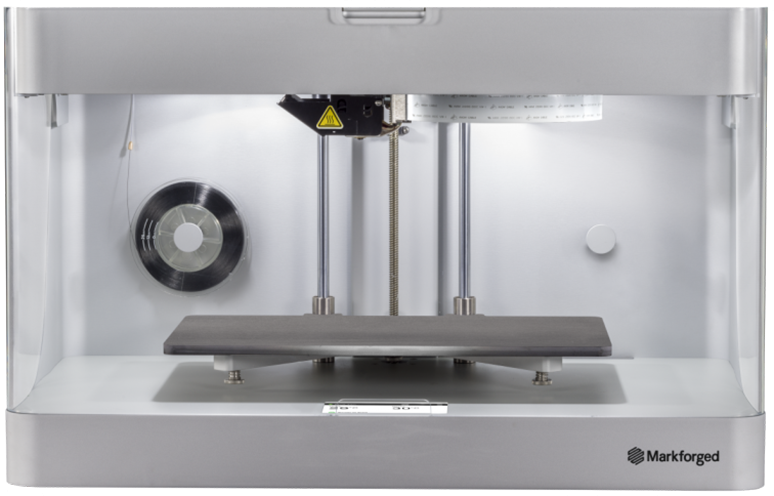

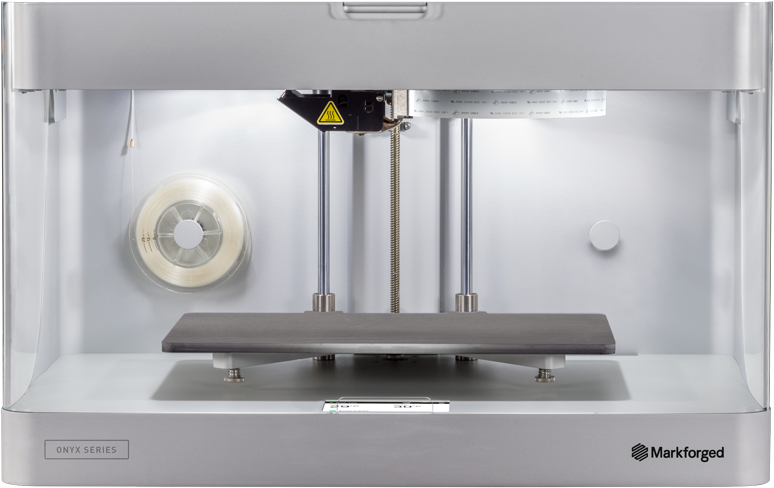

Markforged Desktop 3D Printers

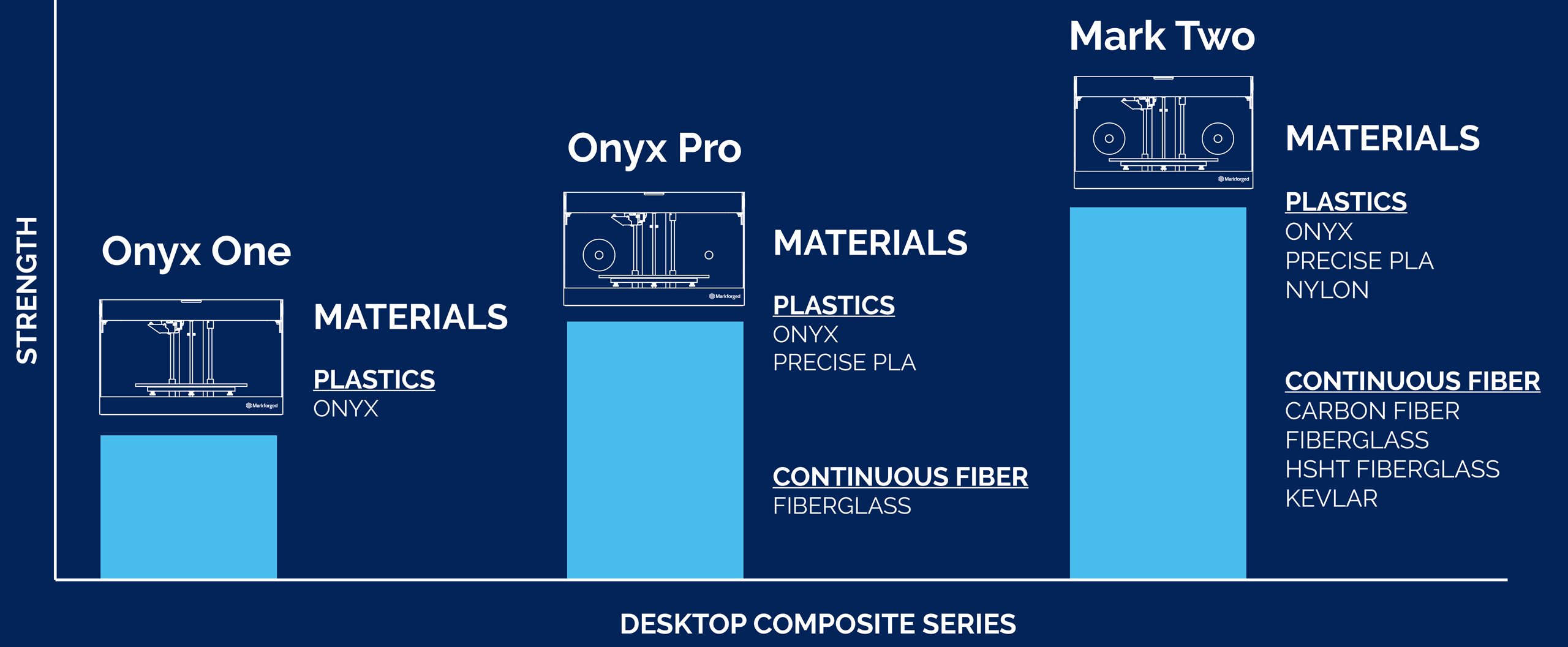

The Markforged 3D desktop printer series consists of three models with overlapping capabilities. These printers are perfect for prototyping, with a wide range of 3D printing capabilities. All share the same basic platform, with the main difference being the ability to print with more advanced filaments. All, including the affordable Onyx One, work with a carbon fiber-filled nylon filament, while the Onyx Pro and Mark Two can also print with continuous fibers.

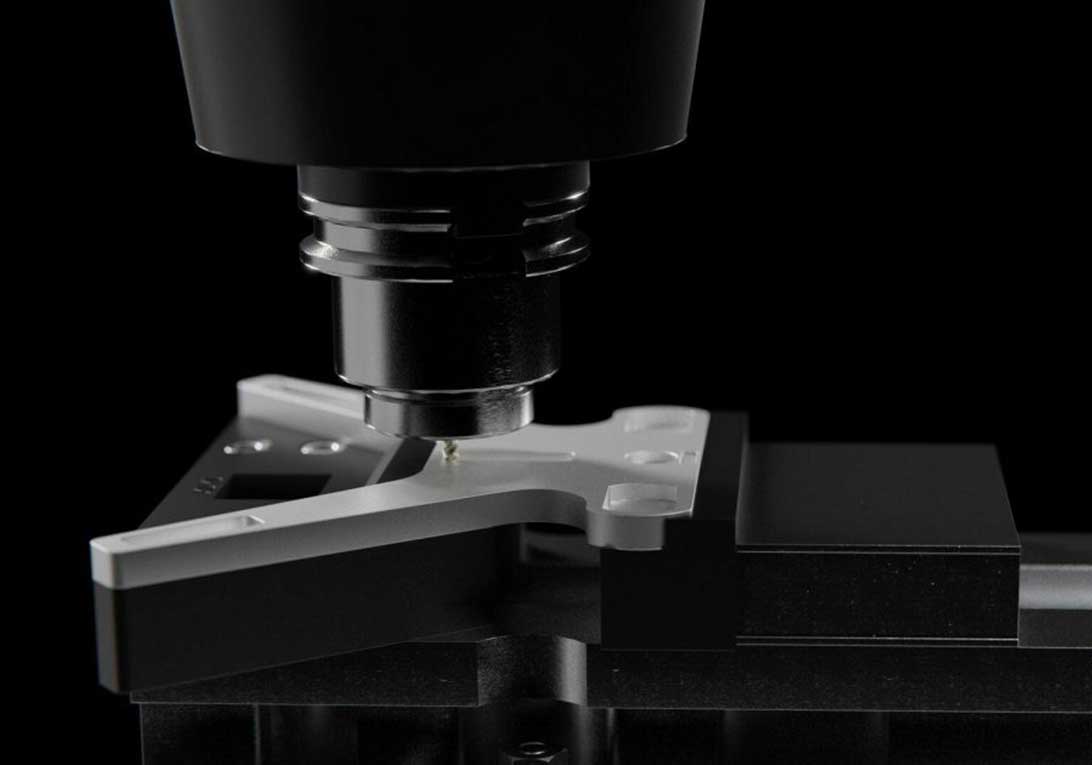

The Mark Two is a composite printer that can produce parts with unparalleled strength, capable of replacing machined aluminum. With dual print heads, it can reinforce your parts using layers of carbon fiber material to produce aluminum-strength parts.

Compact Dimensions

All desktop printers share the same office-friendly footprint of 23" x 13". These printers use a compact Drybox that contains the filament holder, which is placed next to or behind the printer. Models that are compatible with fiber reinforcement also have an internal fiber spool holder.

Desktop 3D Printer Series Capabilities

Desktop 3D printers can produce end-use parts with a manufacturing tolerance of between 0.004 inches and 0.008 inches, depending on layer height. They can print concept models and functional prototypes up to 12.6" x 5.2" x 6" in size. They have a precision composite print bed with a kinematic coupling to ensure proper alignment when reinstalling the base for a seamless 3D printing experience.

The precision design and construction of Markforged 3D printers yield predictable, repeatable results. They are built to create strong parts, consistently, and reliably. Period.

Fused Filament Versus Continuous Filament Fabrication

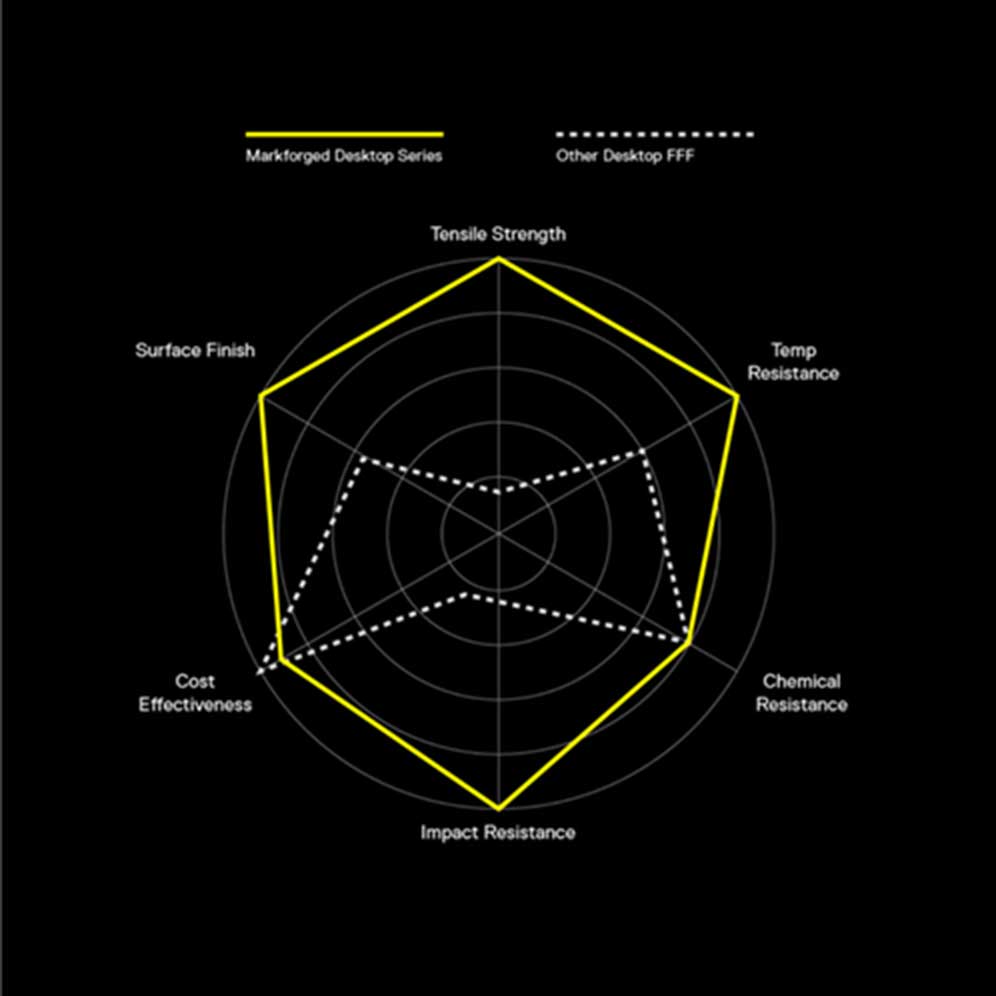

Fused filament fabrication printing materials are homogenous plastics melted by the extruder and laid down as soft beads that fuse as they cool. They are ideal for cost-efficient prototypes. Markforged Onyx base fused filament material contains micro carbon fibers to improve surface finish, strength and toughness. The continuous filament fabrication process adds a continuous filament of fiberglass, aramid or carbon fiber through a second print nozzle, which significantly increases component tensile strength. Additionally, using Markforged's Eiger online software, users can lay fibers to increase the strength of load-bearing parts.

Versatile printer

Create production-grade parts and products quickly and affordably right from your desk using a variety of materials.

Dual print heads

The Mark Two and Onyx Pro have a dual nozzle extrusion system capable of simultaneously fusing fibers and plastics to make parts as strong as metal.

Cloud driven

Eiger is an integrated platform that quickly takes you from CAD to functional part. Its browser-based toolset enables you to slice and print parts with a single click, or drill deeply into part settings to optimize your final product.

Applications

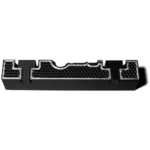

What Can I Build on a Desktop Printer?

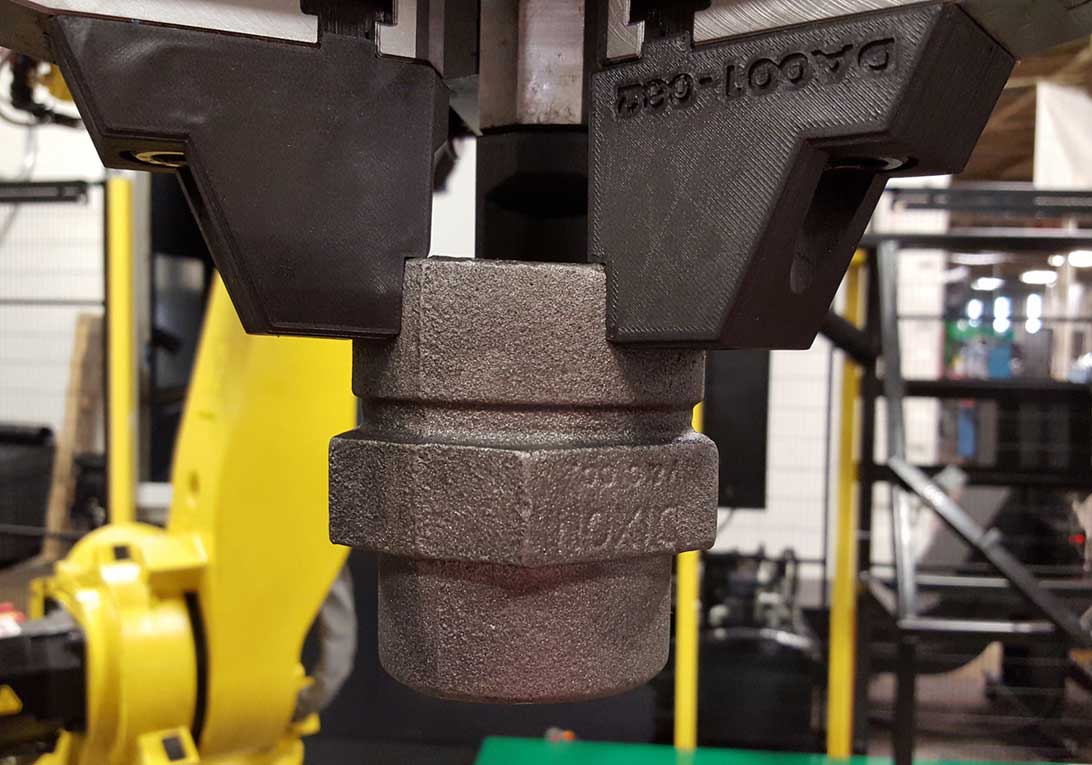

Build all your jigs, fixtures and tooling in-house with 3D printing. From custom soft jaws for difficult machining operations to alignment jigs for welding, a Markforged 3D printer can improve many of the behind-the-scenes tasks associated with manufacturing and fabrication.

Enhance your manufacturing floor with a Markforged printer and experience shorter lead times, increased machine bandwidth, streamlined part production and reduced manufacturing costs.

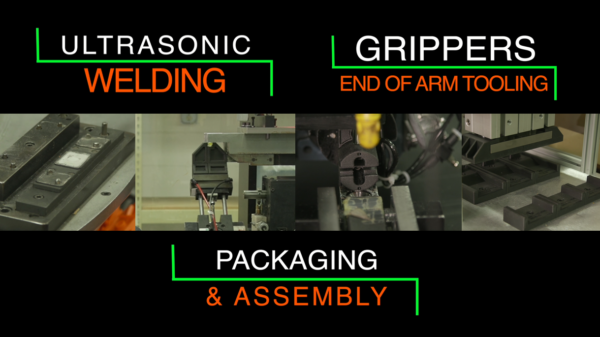

Johnson Level purchased the Mark Two industrial grade printer and saw ROI within 9 months. New 3D parts make up their production line including an ultrasonic welding fixture, multiple grippers, packaging prototypes and a new assembly machine.

Watch Our 3D Printing Tour

Watch our On-Demand 3D Printing Germantown Technology center tour with a staff guide. These printers include metal, composite, and thermoplastic machines from Markforged 3D Printing