Migrating to a new CAD system can seem complex, but it comes down to managing two things: data and people.

THE DATA SHUFFLE

It’s very rare for a company to move all of their old data into SOLIDWORKS because it does not all have to be there. The data that needs to come over doesn’t always have to be converted, either. Consulting firm Tech-Clarity found that only half of a company’s forward-moving legacy data ends up being converted into SOLIDWORKS format. That study was conducted before the advent of 3D Interconnect technology, which precludes the need for translation in a variety of scenarios.

Strategies for Data Migration

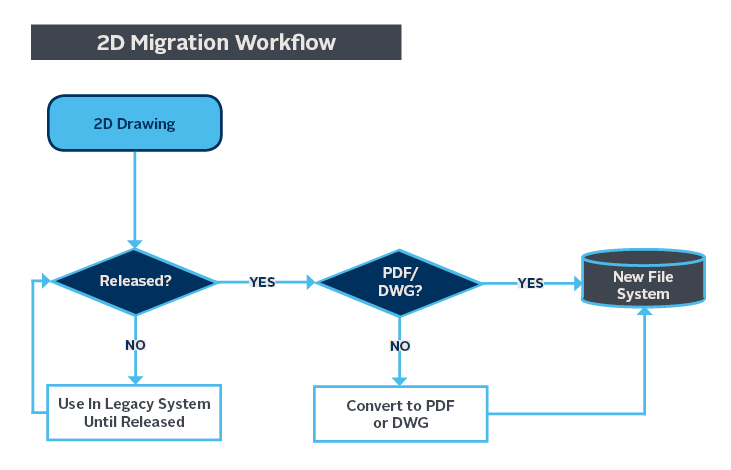

2D data that is view-only, such as released drawings in PDF or DWG format, can be kept as-is. If the 2D data is still in work, then it should be kept in the original system until it becomes released. Expressed as a workflow, it would look like this:

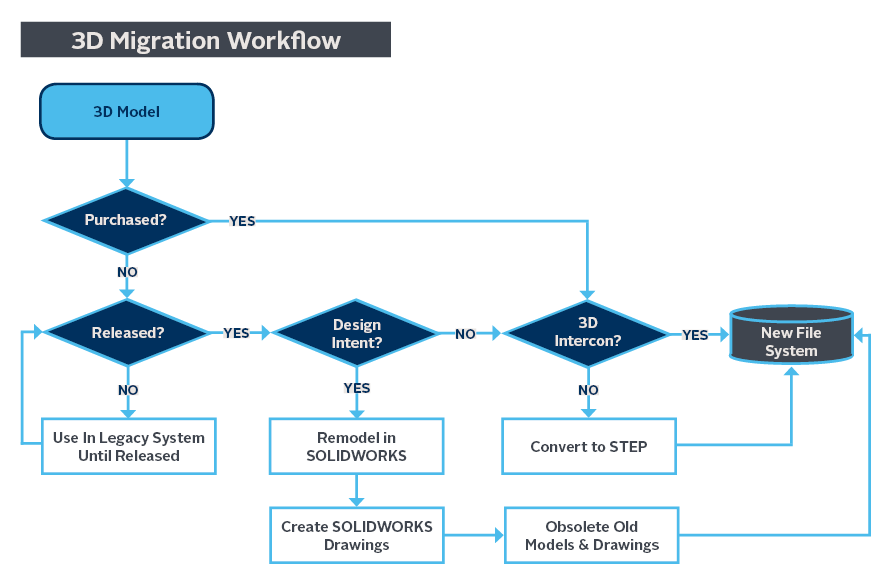

3D data of items that you purchase, but don’t change, is likely in a STEP or other neutral format – they can be used in the same way with SOLIDWORKS.

3D data that is in PTC, Autodesk Inventor, Siemens NX/Solid Edge, or CATIA V5 format can be used directly in SOLIDWORKS assemblies as components or subassemblies. Using the new 3D Interconnect technology introduced in SOLIDWORKS 2017, these items will retain their associativity to the original files, so if they are changed in the native CAD system, the SOLIDWORKS assembly will allow you to update from those changes.

3D data that is specifically in Autodesk Inventor or PTC can also be directly translated into SOLIDWORKS with some feature history and parametric information intact. The success of this largely depends on how the models were created.

3D data that needs specific design intent will need to new SOLIDWORKS models created and the old files obsoleted. Corresponding SOLIDWORKS drawings will also need to be created, and the old drawings obsoleted.

A high-level workflow showing these steps and decisions would look something like this:

Manage Data and Process

With SOLIDWORKS PDM Professional, you can dump everything you already have in the vault and go from there; it’s much easier to clean up duplicate files and classify data once it’s in a database-driven vault system. Because SOLIDWORKS PDM Professional manages native SOLIDWORKS, DraftSight, AutoCAD, Inventor, Creo, and Solid Edge files, all users can work comfortably in the same environment.

SOLIDWORKS PDM Professional’s multi-CAD capability also enables everyone to participate in data management workflows, and this is a very powerful way to guide users through the data migration process you have established. Legacy CAD files and new SOLIDWORKS files can reside in the same project folders, and old files can be obsoleted as users progress through their workflows, automatically changing the access and visibility of those files. Workflows also allow for automated notifications, approvals, and file conversions – say, to an output DXF or PDF – to ensure data integrity as the migration process continues.

The People Factor

People have certain skills and processes they have learned while using the legacy system. To make the most of SOLIDWORKS, users will need skills training – you don’t want them to use your new system in the same way they used the old one! In-person, classroom-based instruction is the most effective, and there will be a variety of courses your users will want to complete. In addition to SOLIDWORKS application training, process training will help everyone smoothly walk between systems, knowing how to handle legacy data.

If you have people with previous SOLIDWORKS experience, it is possible they will need less training than the rest of the group. A GSC SOLIDWORKS Productivity Assessment will reveal the proper training start point for those individuals. Experience varies widely from person to person, so having an assessment to uncover any knowledge gaps is essential.

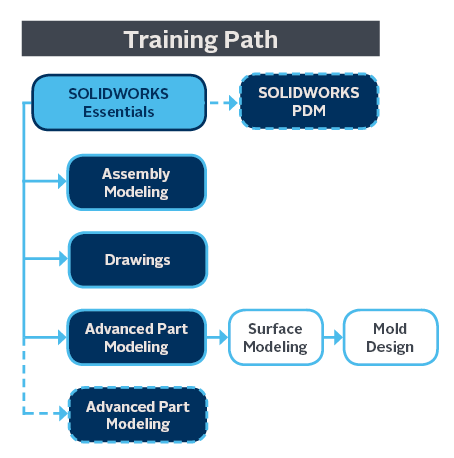

Training paths for specific types of users are a good place to start when creating an overall training plan. GSC has a dozen training paths identified, such as the Mold Designer Training Path below. Note that each class after SOLIDWORKS Essentials has at least one pre-requisite class, which is done to ensure students have the full range of knowledge and skills necessary to be successful in each subsequent class.

Struggling to Find People Trained on Your CAD System?

If you’re having trouble hiring people who already know your design tool or you’re frustrated with the lack of flexibility in your CAD vendors licensing, you may want to switch to the SOLIDWORKS platform and join its vast community of 5.1 million users worldwide.

The process of changing from your current 3D CAD system to SOLIDWORKS may seem daunting, but it’s easier than you think. Download our ebook, “Break Out of the Bubble: Changing CAD Systems is Easier Than You Think,” to learn more. It’s more than just a catalog of options, you’ll find sound advice on setting up the best path to get your whole team moved over to SOLIDWORKS.

Share

Meet the Author