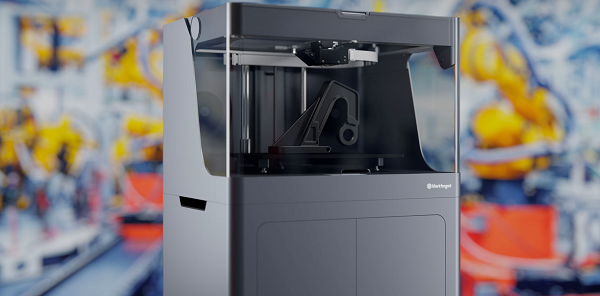

So, What Makes Markforged Different?

There are so many 3D printers on the marketplace today that it can become incredibly confusing to sift through them all. There are a plethora of 3D printers that can create parts with decent dimensional accuracy and with acceptable material properties. Want to make a plastic dragon for your nephew? Just about any 3D printer can do that. So, what makes Markforged different?

It all boils down to the amazing engineers at Markforged, the Onyx 3D printing material, and the ability to introduce Continuous Fiber Reinforcement into a part. Sound impressive? Trust me. It is.

The Magic of Markforged Onyx

Onyx is Markforged’s proprietary nylon / chopped carbon fiber blend material that serves as the primary printing material on their entire line of Markforged 3D printers, from the Onyx One to the flagship X7. Standard nylon can also be run on many of the printers, but odds are once you work with Onyx parts, you won’t be going back. Onyx offers terrific surface finish, incredible dimensional stability, chemical resistance, and heat resistance all while being 40% stiffer than ABS.

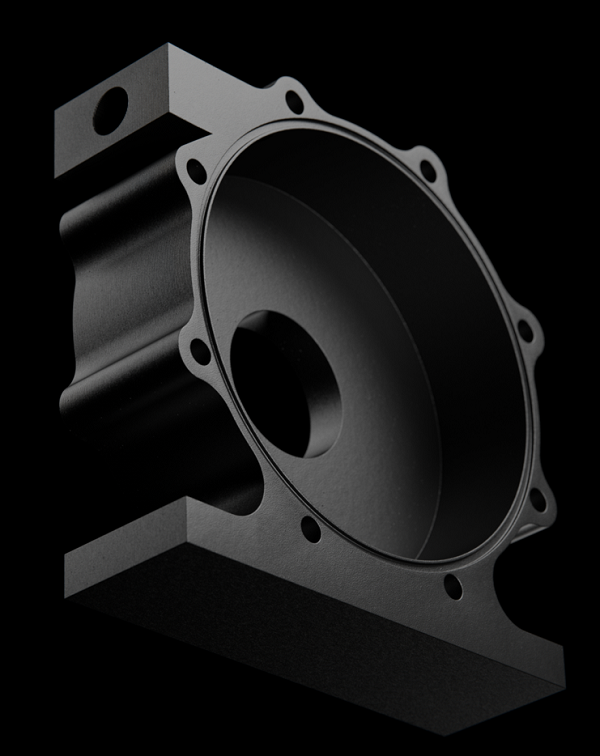

Have you ever looked at a 3D printed part from a typical FDM or FFF style printer and immediately noticed layer lines on nearly every surface? The Onyx material dramatically reduces these visual blemishes on nearly all surfaces to the point that it is often no longer noticeable to the naked eye. After coming from years of working with FDM parts, the surface finish, crisp edges, and robust living hinges capable with the Onyx material on the Markforged printers have absolutely blown me away. In my humble opinion, no other FFF style printer even comes close.

The desktop printers can print at a layer resolution down to an impressive 100 micron (.004”) and the industrial printers can print down to an almost absurd 50 micron (.002”) layer resolution. Combine that incredible resolution with the inherently crisp and smooth surface finish of the Onyx material and you are left with a part that requires no post-processing to look and feel amazing.

How Continuous Fiber Changes the Game

Now, the term “Game Changer” gets thrown around in the 3D printing industry a lot. Nearly every day another company is claiming to have created a groundbreaking 3D printing technology, very few are what they claim to be. But the Continuous Fiber Reinforcement that Markforged has brought to the table definitely merits Game Changer status. This stuff can throw down. Continuous Fiber Reinforcement is what takes an incredibly strong Onyx part and makes it a superhero.

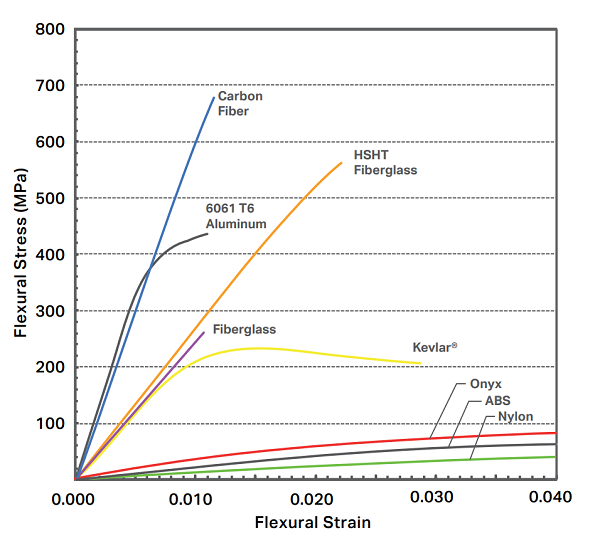

Markforged pioneered fiber reinforcement in 3D printing, and the impact it has on the strength and durability of 3D printed parts is absolutely staggering. By introducing continuous strand carbon fiber into a part you are able to create a composite part that is up to 8x stronger than ABS and 20% stronger than 6061-T6 Aluminum! Need a part to take an absolute beating? Try introducing Kevlar and create a part with 8x the impact resistance of ABS. These parts are no joke.

What are Composites?

So, what is a composite part? Composite parts are parts made up of more than one material that, when combined, have synergistic properties different from the original materials. There are 2 main components of composite parts: a matrix and a reinforcement.

In our composite parts the Onyx is the matrix material, and our reinforcement comes from one of 4 continuous strand fiber options:

- Carbon Fiber

- Kevlar

- Fiberglass

- High Strength High Temperature Fiberglass

By introducing these continuous fibers into the Onyx part we are able to quickly, reliably, and inexpensively 3D print parts with mechanical properties never before thought possible from 3D printed thermoplastic parts. These parts are no longer just for show or for prototyping, these parts are ready for primetime. Be it an end-use part for a small production run, or a part designed to replace aluminum or even steel tooling and fixturing on a production line, these parts are ready to work, and work hard.

If you’ve been under the impression that 3D printers can only make plastic toys and trinkets, or that no thermoplastic 3D printer could create parts strong enough for your application, I encourage you to stop in at our Germantown Technology center and check out the reinforced parts we have on hand, or speak with our 3D printing team (call us at 800-454-2233) to have a part 3D printed for you and see and feel the difference for yourself.

Markforged has truly set a new standard. 3D printing isn’t just for dragons anymore.

Share

Meet the Author