Markforged FX10

The world's first metal and composite printer

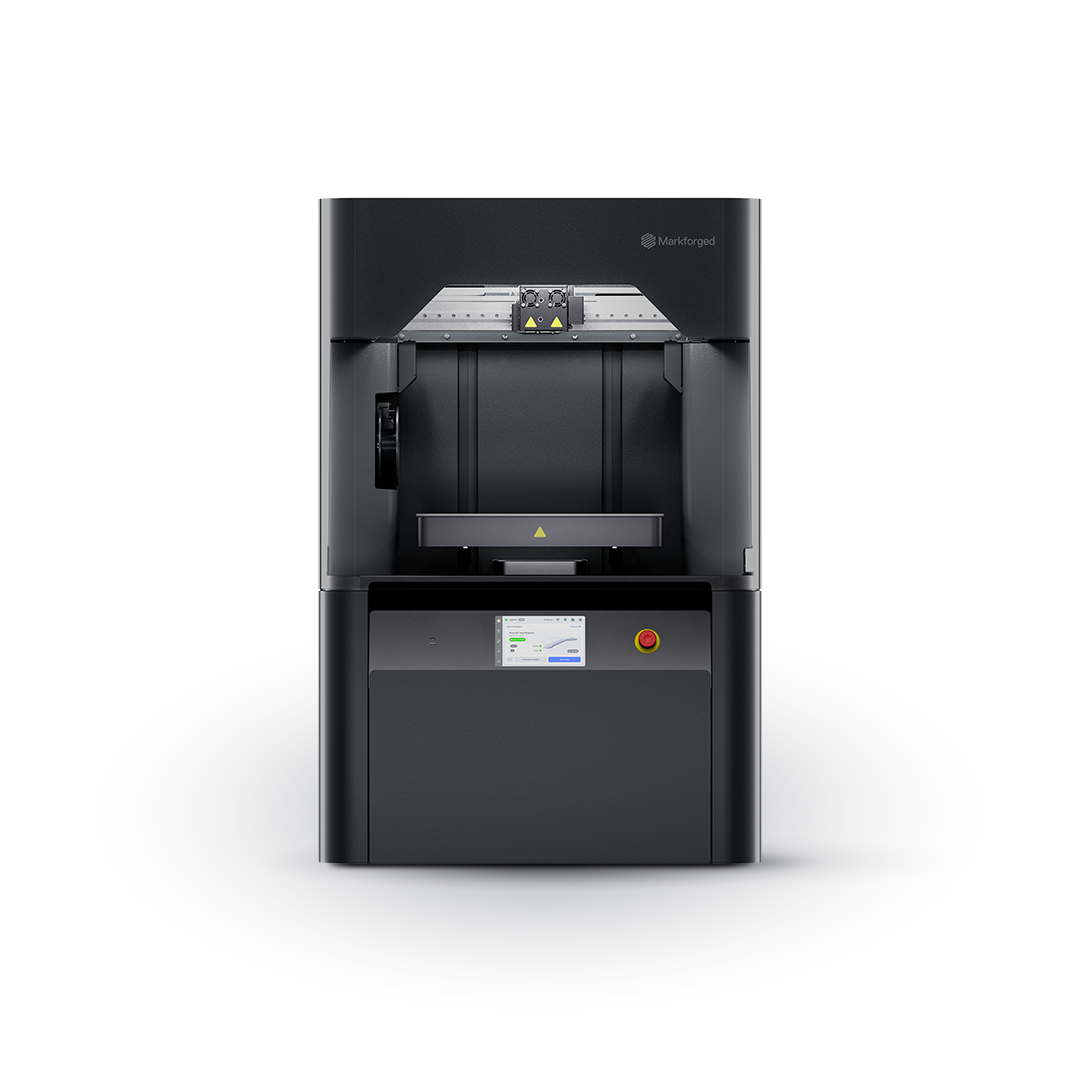

FX10

FX10 is the first industrial metal and composite 3D printer —the product of years of engineering innovation and technological advancement. Built on the success of the Markforged X7 and Metal X, FX10 quickly delivers strong, accurate tools and fixtures to your factory floor.

FX10 features a modular print system that enables users to swap between metal and composite print engines quickly and efficiently. All FX10s have composite capability, with metal capability as a purchasable add-on. Printhead-mounted optical sensors can verify the dimensional accuracy of parts and assess device health and performance. FX10 utilizes automatic calibration and material changeover, yielding a simple, low-touch user experience that mitigates the need for dedicated operators.

METAL

A 2nd Generation Metal FFF print engine leverages Markforged’s house-made metal filaments to print green parts, which can be washed and sintered into production-ready metal parts.

Composite

A 5th Generation CFR+FFF print engine builds on the success of previous Markforged machines to already offer best-in-class composite print performance.

The Digital Forge: Powered by SoftwarE

Markforged offers a simple, smart, scalable additive manufacturing platform designed to seamlessly fit into your manufacturing operation. Our software Eiger™ was built for scale delivering a single user-experience, digital part repository and fleet management across the entire Markforged portfolio, including the FX10.

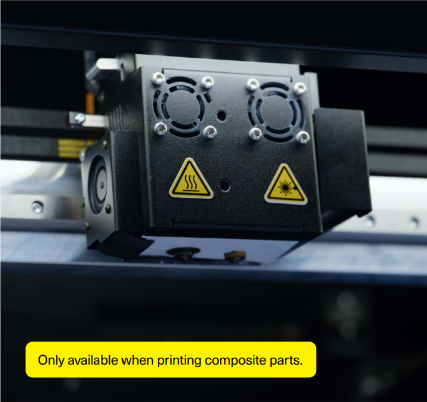

Vision Module & Laser Micrometer

FX10 features two printhead mounted

optical sensors. The laser micrometer

powers Inspection — in-print dimensional

validation — and machine calibration while

the new Vision Module will capture detailed

images of calibration parts to determine and

optimize printer performance.

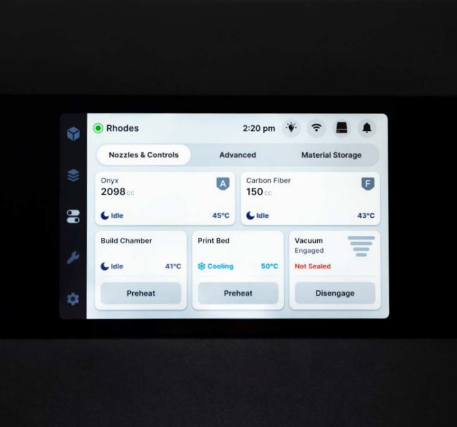

Heated Build Chamber & Vacuum Bed

The FX10 has a large chamber that heats to

60 °C, useful for printing high-quality parts at high speed. The aluminum vacuum bed is also heated and utilizes precision-machine grooves that are scanned by the laser micrometer for calibration.

Large Touchscreen with Intuitive Interface

FX10 features a 7” touchscreen. Users can

start builds, monitor machine status, manually control the machine, and start automated calibration routines all in one place.

Advanced Material Cabinet

An inboard material cabinet stores four

spools in individually sealed compartments

that support auto material changeover and

fast spool loading for metal and composite,

reducing user intervention.