To succeed in a fast-paced industry, delivering superior solutions quickly and cost-effectively is essential. To outperform the competition, it’s crucial to have a product development process that adds value at every stage of the product’s life cycle. By integrating 3D printing throughout the design process – from concept to post-market – traditional manufacturing methods can be bypassed, saving both time and money while expediting the device’s launch to the market.

Using 3D printing to get tools in surgeon’s hands faster

3D printing is a reliable technology that provides state-of-the-art capabilities to enhance your competitive advantage, particularly in the medical device industry, where it can accelerate innovation. Medical providers can obtain custom parts on the same day at every product’s life cycle stage, using an agile platform for digital parts fabrication. This technology also enables testing of new concepts in-market with high-quality production-grade parts, allowing engineers and designers to create products that better meet customer needs at a fraction of the cost of traditionally machined parts.

Empower medical professionals

With Markforged 3D printing technology, you can quickly manufacture functional parts with minimal overhead, providing medical professionals with products faster than ever before. By embracing the downstream effects of early customer feedback, you can create better products in less time, providing significant advantages over traditional manufacturing methods.

Adaptable solutions for unique problems

Use 3D printing to create custom solutions for unique problems that require unconventional approaches. Markforged offers a wide range of performance materials for functional parts, making it ideal for prosthetics, prototypes, and custom workholding. 3D printing enables adaptive designs, expanding the possibilities for what can be fabricated.

Service better

Turn maintenance into a competitive advantage by providing customers with unparalleled expediency and quality with distributed manufacturing. Quickly and effectively maintain parts in the field without disrupting your or your customer’s operation.

Speeding time to market

By leveraging 3D printing technology, you can quickly iterate on designs and test different approaches more frequently without incurring the high costs and long delays of traditional manufacturing. This flexibility allows you to make necessary changes and quickly adapt to evolving requirements.

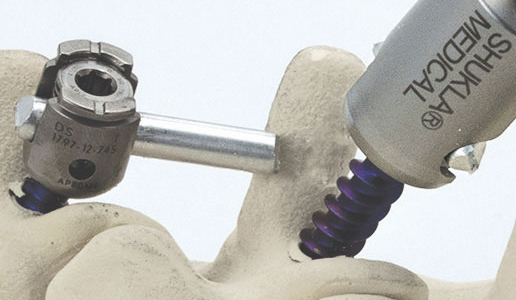

Shakula Medical invests in Markforged 3D printing

Shukla Medical is a leading manufacturer of universal orthopedic implant removal tools used by surgeons worldwide. Seeking a more cost-effective approach to prototyping, their engineers and designers turned to the Markforged Metal X system. Over 100 top manufacturers, including Shukla Medical, leverage the Markforged platform to accelerate product development and market products faster.

Why invest in Markforged 3D printers?

- Access unparalleled design freedom with the widest variety of performance materials in the industry

- Reduce the distance between you and functional parts

- Leverage Continuous Fiber Reinforcement to 3D print parts with excellent strength-to-weight ratios

High-value medical applications:

- Functional prototypes

- Conformal tooling

- Custom prosthetics and orthotics

- Brackets, sensor mounts, and housings

- Assembly fixtures

Contact us

Want to see what 3D printing can do for your company? Contact our additive manufacturing experts or request a 3D printed part.

Share

Meet the Author