Challenge

Machined fixtures are effective but are time-consuming and expensive to produce. Modular fixtures are cheap but difficult to assemble. Hacked-together solutions tend to produce poor-quality welds.

Solution

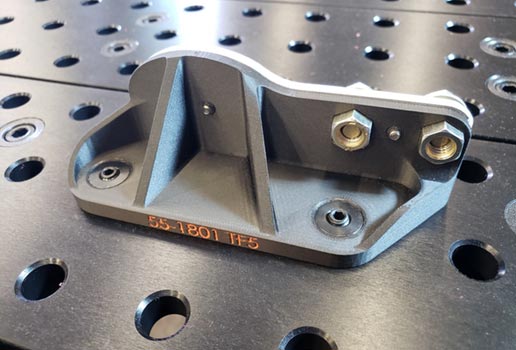

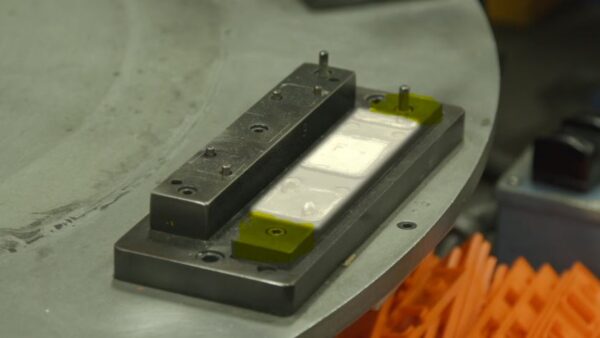

Markforged 3D printed composite welding fixtures combine excellent quality with low cost. These work-holding fixtures are heat-resistant enough to hold the vast majority of welded parts. You can easily design fixtures to hold even the most complex assemblies, securely and accurately. If a fixture breaks, it can easily be reprinted.

Impact

Optimize Fixtures: Reduce the need for the time-consuming fabrication of often-imperfect weld fixtures and take the guesswork out of welding setups.

Save time: Dramatically reduce assembly and welding setup times.

Save money: Increase fixture accuracy and repeatability while allowing skilled labor to focus on making products, not building fixtures to hold them.

Reduce physical fixture inventory: We’ve seen fixtures collect dust for years and take up precious space. Markforged’s Eiger software allows you to switch/transition to a digital inventory for fixturing that is rarely used. If the welding design changes or the project is needed at a future date, it’s easy to print a new, updated fixture.

FIND THE RIGHT TOOL FOR YOUR APPLICATION

Composite Printing

Solutions

Metal Printing

Solution