How to Make 3D Printing

Part of Your Manufacturing Process

The Additive Team at GSC recommends 3 common strategies that industry leaders follow when developing a business plan to bring additive technology into the manufacturing process.

- Aligning the right technology with the right application (e.g. fixtures/tooling, prototyping, production parts).

- Developing a dedicated role to champion and manage additive technology.

- Spreading the word internally on how existing processes can benefit from additive manufacturing.

We can jump-start your additive strategy by working with you to assess your needs and recommend the right technology.

3D Printing Your Production Jigs,

Fixtures, & Tooling

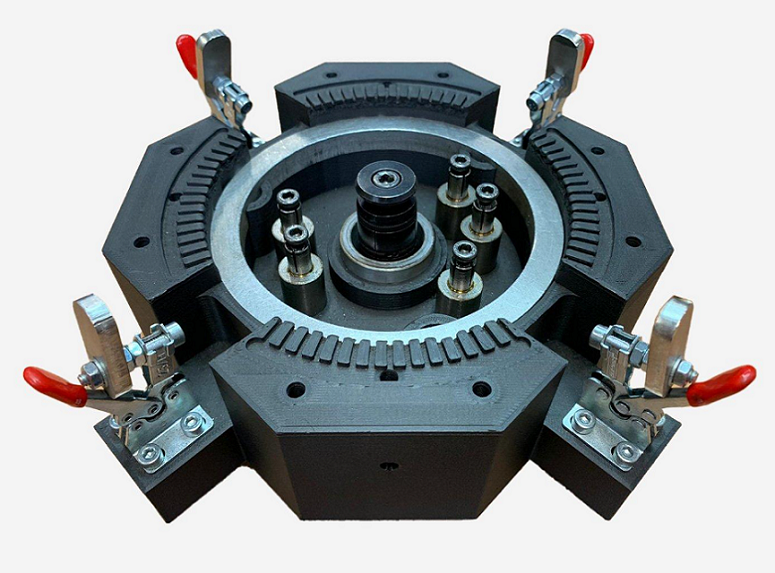

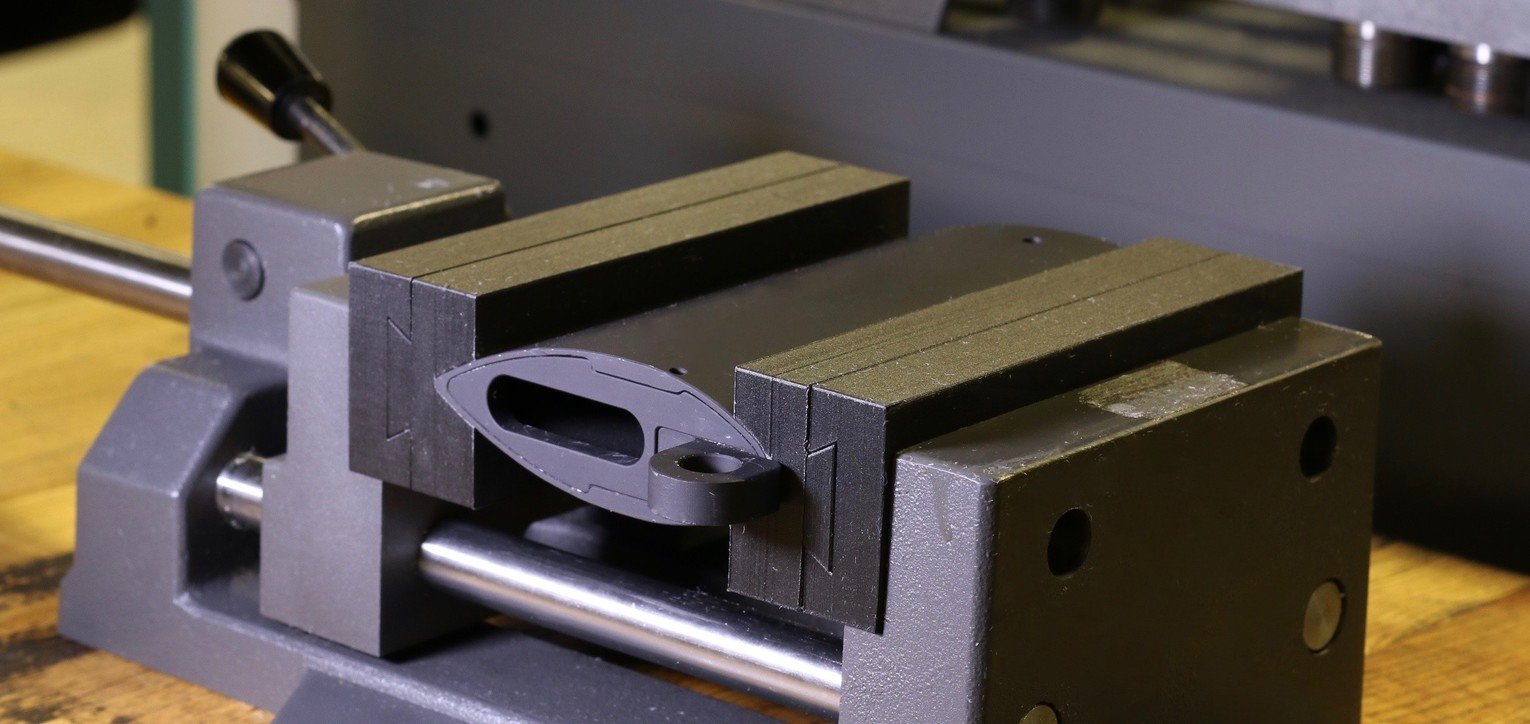

Make all of your jigs, fixtures, and tooling in-house with 3D printing. Control your time and your wallet with the ability to make custom parts as you need. Our customers have had emergencies happen, and reverse engineer and 3D print critical parts to save themselves from prolonging their downtime. Now that's the power of a 3D printer built expressly for manufacturing.

During Production

Respond immediately. Respond quickly. Improve assembly or quality assurance processes. These 3D printed parts can take a beating. Wear and tear is not an issue with these hybrid parts (composite and metal), and with reinforced materials for insane strength. You can also 3D print injection molds to still save compared to traditional processes and while retaining control.

- Jigs and fixtures

- Custom equipment

- New manufacturing aids

- Injection molding

3D Printing Your End-Use Parts

Whether you're a small company or a global enterprise, 3D printed parts are saving you valuable time. We're reducing steps it would normally take to make complex parts, and in a cost-effective way, with numerous hidden benefits.

Skip Ahead to Immediate End-Use Parts

3D print metal parts. 3D print high-strength composites. Whether you're a foundry, in consumer goods, or packaging, the list goes on, our customers ranging from Valmet Foundry to Johnson Level have found ample use and ROI within months of purchasing their 3D printer. Short run production gives you the flexibility you need to change on the fly. Mass customization is now the rule, not the exception.

- Metal parts, metal casting

- Short run production

- Mass customization options

Bye-Bye Brittle,

Hello Tough 3D Printed Parts

3D printing for manufacturing is here, and has been available for a while. Industries such as aerospace, automotive, defense, consumer goods, medical, and more are adopting 3D printing, also known as additive manufacturing (think the opposite of subtractive manufacturing, or CNC machining). 3D printing is empowering a number of companies to respond quickly and manufacture at the point of need.

Use 3D Printing Across Your Supply Chain

Tighten up your supply chain, strengthen any weak points in production, get to market faster while saving time and money along the way (and we have the ROI to prove it to you).

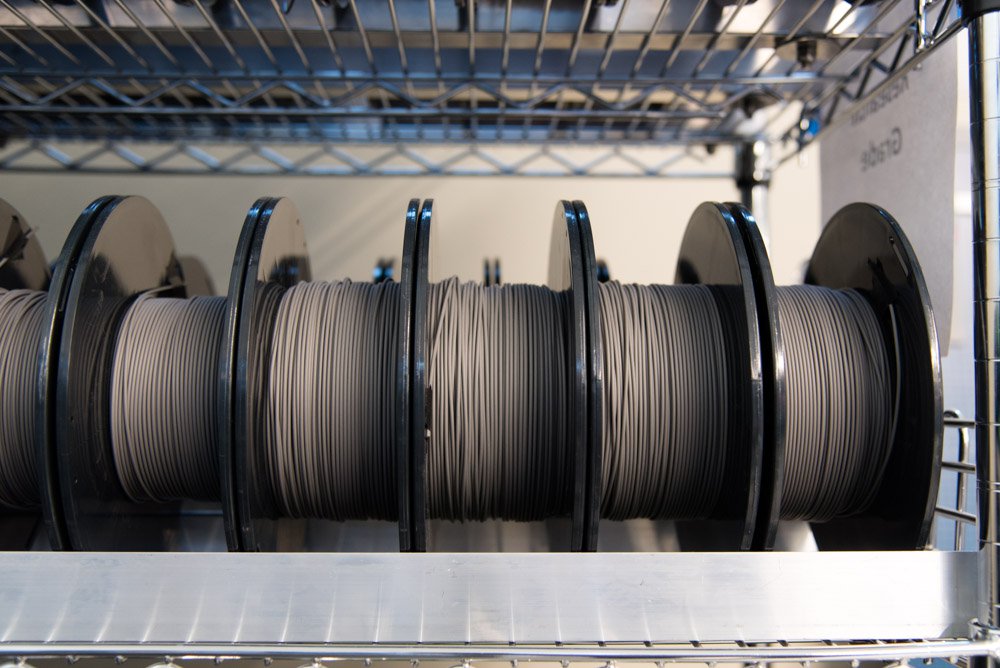

No longer just for prototyping, 3D printing for manufacturing has unlocked applications across your production. Nimble, movable, affordable desktop 3D printers and the strong materials available have opened doors to precise, functional 3D printed parts that stand in for final parts, and can take a beating on the factory floor as manufacturing aids.

3D Printing is Your One-Stop Shop -

Your Machine is a Production Engine

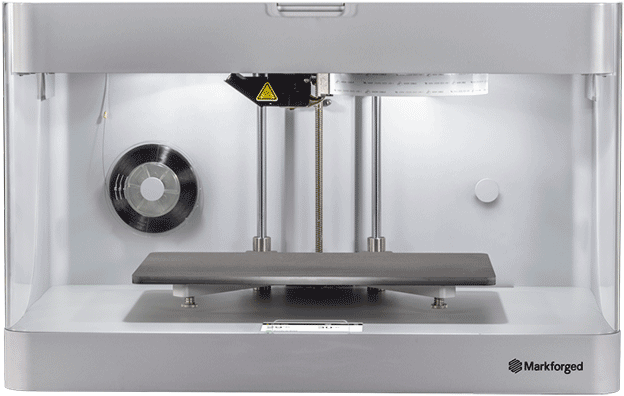

3D printing for manufacturing is about the most advanced manufacturing technology on the market. We provide you with professional, industrial, and production-ready 3D printers. Accurate, repeatable, and reliable processes are in place.

"We are not just a 3D printing company. We are building a platform that enables our customers to move manufacturing to the point of need. The digital forge is a combination of hardware, software, and materials."

- Shai Terem, Markforged CEO

Customer Success Stories

ROI In As Little As 9 Months

GSC Customer Success Story

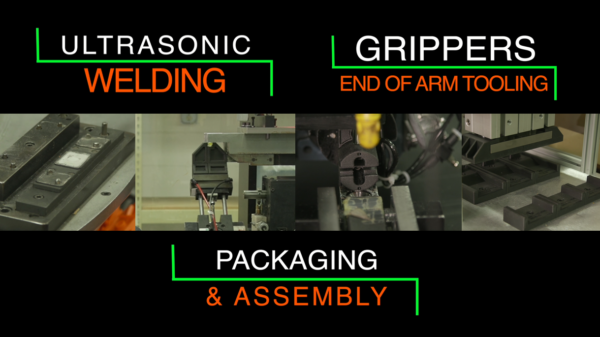

Johnson Level purchased the Markforged Mark Two 3D printer and saw ROI within 9 months. New 3D parts make up their production line including an ultrasonic welding fixture, multiple grippers, packaging prototypes and a new assembly machine.