Challenge

Designing, prototyping, and fabricating tools for production can be the most expensive and time-consuming portion of the product development cycle. Depending on the complexity of the tool, lead times can be weeks to months, and any changes to the tool’s design can delay the process even more.

Solution

High-strength 3D printing enables you to design customized tools optimized for the job without traditional machining constraints. Quickly build tooling designs directly from your CAD model and have them ready for production quickly.

Impact

Save Money: Free up machine shop resources and minimize skilled labor spent on non-revenue-generating parts and tools.

Geometric Freedom: Create complex tools that can be manufactured in low volumes at minimal cost.

Save Time: Quickly optimize your tool’s design in a matter of hours and improve the ergonomics of your part.

Customer Success Story:

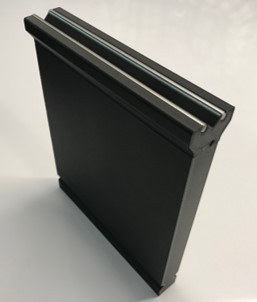

Zero Tolerance 3D prints a Faster Manufacturing Floor

Zero Tolerance increased the output of their manufacturing floor by more than 50% and made the molding process safer for their staff. See how they designed the part that transformed their business.

FIND THE RIGHT TOOL FOR YOUR APPLICATION

Composite Printing

Solutions

Metal Printing

Solution