Challenge

Functional prototypes offer a way for engineers to test designs before manufacturing them at scale. This involves producing usable parts on a one-off basis, which can be expensive and time-consuming. Often, they must be sent to an outside shop for machining, which can add weeks to the product development process. Additionally, because functional prototyping happens in the design stage of manufacturing, part designs frequently go through multiple iterations, which means more resources must be dedicated to create each one.

Solution

3D printing enables you to produce functional prototype parts in-house, with minimal labor and at a lower cost than other methods. Tooling and retooling costs are eliminated. You can iterate with shorter lead times, reduce fabrication costs, and get products to market faster.

Impact

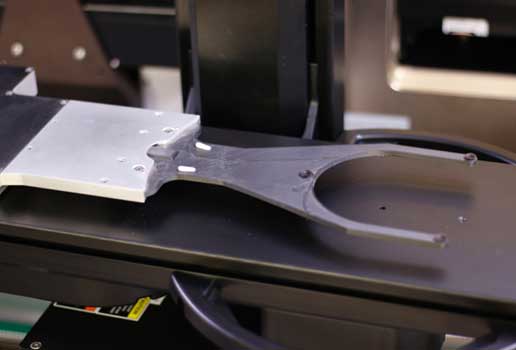

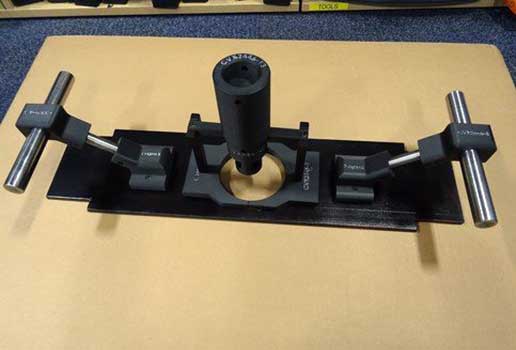

Useable & Testable parts: Replicate final part properties without relying on machine shop resources.

Save Money: Rapidly design and make changes to parts on-demand.

Iterate Faster: Get products to market faster with shorter lead times.

FIND THE RIGHT TOOL FOR YOUR APPLICATION

Composite Printing

Solutions

Metal Printing

Solution