Challenge

Machining and custom milling soft jaws for difficult-to-hold parts is time-consuming, difficult, and expensive to design and program. Workpieces with complex geometry that are too complex to hold with a standard vice jaw can be a hindrance to your manufacturing workflow.

Solution

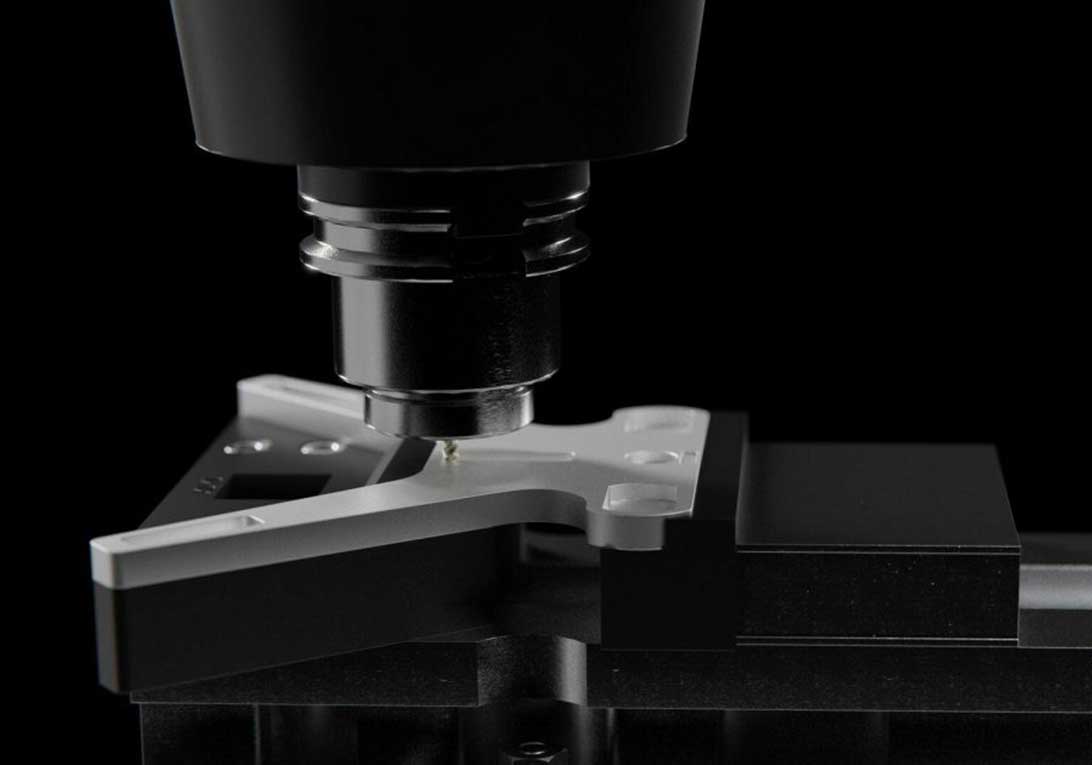

With the help of continuous fiber reinforcement, 3D printed soft jaws can be created to hold metal parts for most machining and turning applications. They are strong enough to hold parts without marring their surface, chemically resist cutting fluids, and provide the reinforcement needed to survive vice clamping forces. Simplify your manufacturing process and easily print your jaws on-demand to fit your parts perfectly.

Impact

Ease of Design: CAD a jaw blank and subtract the part geometry from the blank to create a conformal, non-marring grip surface that is perfectly fitted to the part to be processed.

Save Time: Printing jaws requires no hands-on programming or machining time, and they can print overnight with no oversight. This frees up precious CNC bandwidth for production work.

Save Money: Rapidly create soft jaws faster than traditional machined counterparts at a fraction of the cost.

Specialized Applications: 3D printing gives you the ability to customize workholding for complex applications and create parts to streamline workflows, maximize performance and enhance safety.

FIND THE RIGHT TOOL FOR YOUR APPLICATION

Composite Printing

Solutions

Metal Printing

Solution