SOLIDWORKS Plastics

Simulate how melted plastic flows to avoid effects like warpage, on parts. Gain mold cooling optimization. Change mold geometry, processing conditions, or the plastic material to eliminate potential defects.

SOLIDWORKS Plastics Packages

Standard

For plastics part designers, optimize parts in the early stages of design.

- Modify designs at the same time you optimize for form, fit, and function

- Fully embedded within SOLIDWORKS CAD environment

- Easy to learn and use

Professional

Designers and injection mold makers gain an accurate, easy-to-use method for optimization. Includes Standard capabilities.

- Quickly create single-cavity, multi-cavity, and family mold layouts, including sprues, runners, and gates

- Balance runner systems and estimate cycle time, clamp tonnage, and shot size

- Optimize feed system design and avoid costly rework

Premium

Allow CAE analysts and mold designers to analyze mold cooling line layouts and predict molded part warpage. Includes Professional plus advanced simulation functionality.

- Optimize cooling system design to minimize cycle times

- Design simple or complex mold cooling line layouts

- Optimize part mold design, material selection and processing parameters to reduce warpage

New in SOLIDWORKS Plastics

Get optimal results faster with the Injection Location Adviser. Expanded runner shapes allow you to create more real-world studies. With enhancements to Symmetry, you can represent multi-cavity molds that solve quicker than ever.

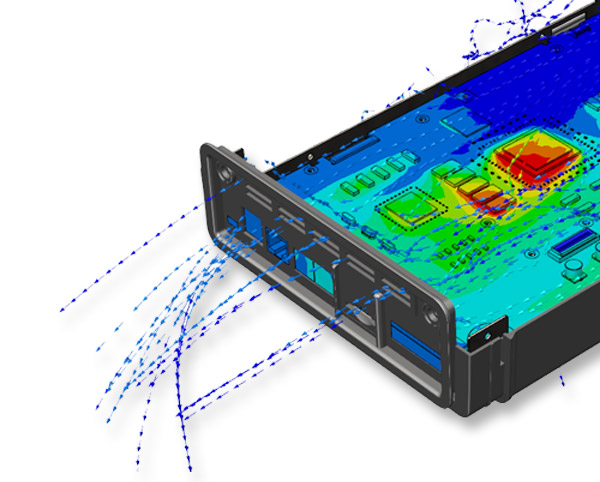

SOLIDWORKS Flow

Run “what if” scenarios, and efficiently analyze the effects on immersed or surrounding components. Intuitive tools like CFD (computational fluid dynamics) enable you to simulate realistic liquid and gas flow with real-world conditions.

Companies across the Midwest, like GE, are comparing design variations to make better decisions about superior performance. Driven by engineering goals, CFD insights informs your technical decisions through a concurrent engineering approach. Add-on tools for detailed analysis include:

HVAC Module: Offers additional simulation capabilities for advanced radiation and thermal comforts analysis

Electronic Cooling Module: Offers electronic virtual models and an extensive materials library for cooling simulation

Features include:

- Analysis of Fluid Flow and Thermal Fluid

- Thermal Comfort Factors

- Electronics Thermal Management

- Simulation Visualization

Newest Features in Flow

SOLIDWORKS Flow Simulation 2022 enables you to save time loading exactly the results display you want with the new Scene Plot. Locate critical results in your design with the new Merged Plots, allowing you to see differences between studies at a glance.

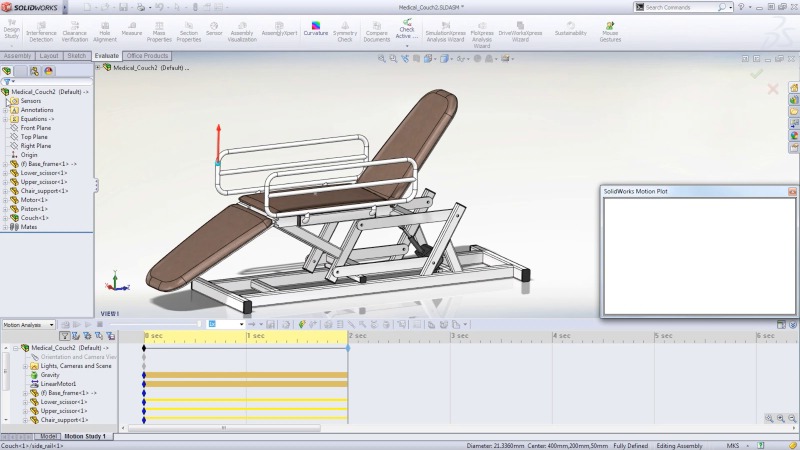

SOLIDWORKS Motion

Kinematic Motion Analysis or Dynamic Analysis

Motion analysis allows you to easily evaluate how your product will move throughout its operational cycle. With real-world visualization, measure the forces and loads on your design. Address rigid body kinematic or dynamic problems. This is a true physical calculation of forces and motions on an assembly.

You can conduct time-based or event-based motion simulation. You can take into account the sizing of motors, actuators; you can understand power consumption and effects. You can also simulate cam-drives and latch mechanisms. Stress Analysis offers a complete performance test.

Calculate the effect of:

- Forces

- Springs

- Dampers

- Gravity

- Component Contact

- Bushings