Metal 3D Printer Minnesota

Key Benefits of Metal 3D Printing Technology

Metal 3D printing is revolutionizing the manufacturing industry, offering unmatched flexibility and efficiency. Whether you’re in aerospace or healthcare, the potential to create complex, custom metal parts is game-changing. With its ability to produce lightweight, high-strength components, this technology is proving crucial in design-driven fields, facilitating innovation and rapid prototyping.

Cost-effectiveness is another significant advantage. By reducing material waste and eliminating the need for expensive tooling, metal 3D printing offers a more sustainable production method. This is particularly advantageous for small-scale manufacturing runs where traditional methods could be prohibitively expensive. Industries in Minnesota are increasingly adopting this approach, capitalizing on its economic and environmental benefits.

The speed at which prototypes can transition from computer-aided design to physical products is another boon for efficiency. This rapid turnaround is invaluable in competitive sectors requiring quick innovation cycles and dynamic product development strategies.

How is Minnesota Adapting to the Metal 3D Printing Revolution?

As someone with over two decades in the industry, I’ve watched Minnesota evolve into a hub for innovative manufacturing solutions. The state boasts numerous companies investing in cutting-edge technologies, including metal 3D printers. The synergy between local tech hubs and manufacturing giants positions the region as a pivotal player in the national landscape.

Metal 3D Printer Minnesota is a phrase echoed throughout industry circles here. Businesses are not only embracing this technology but also pushing its boundaries. The automotive sector, for instance, has leveraged 3D printing for rapid prototyping, enabling faster design iterations and a more streamlined path from concept to market. Similarly, medical device manufacturers use this technology to prototype and produce device components, ensuring precision and quality.

According to industry reports, Minnesota’s commitment to 3D printing innovation is attracting increased investment. Local universities and research institutions are also contributing by fostering a culture of experimentation and learning, preparing the next generation of engineers and innovators.

What are the Common Concerns Related to Metal 3D Printing?

Metal 3D printing might seem daunting due to potential challenges like material availability and cost. However, by addressing these concerns head-on, Minnesota businesses are finding creative solutions. For instance, partnerships with material suppliers ensure a steady supply of high-quality metals tailored to specific industrial needs.

Some question the durability and reliability of 3D-printed metal parts. It’s crucial to note that advancements in technology and material science have significantly mitigated these issues. Modern metal 3D printers, equipped with precise calibration and advanced layering techniques, produce components that meet stringent industry standards.

Another frequently discussed topic is production speed. While slower than traditional methods, the overall development cycle is faster due to reduced lead times in prototyping and iteration phases. This aspect is vital for industries like aerospace, where design precision and part performance are non-negotiable.

In short, while challenges exist, they are not insurmountable. Embracing innovations and strategic collaborations, many companies in Minnesota are turning these challenges into opportunities.

Steps to Successfully Integrate Metal 3D Printers into Your Workflow

If you’re considering Metal 3D Printer Minnesota solutions for your business, understanding the integration process is essential. Here’s a strategic approach:

- Assessment of Needs: Begin by evaluating your specific production goals. Identify areas where 3D printing could offer significant advantages over traditional methods.

- Choosing the Right Technology: Not all 3D printers are created equal. Research different models and capabilities. Consult industry experts if needed to select a printer that aligns with your production requirements and budget.

- Staff Training: Invest in comprehensive training for your team. Familiarity with the technology ensures smooth production and helps in troubleshooting potential issues early.

- Material Selection: Work with suppliers to secure high-quality materials. The choice of metal influences both the quality and performance of the final product.

- Implementation and Iteration: Start with small-scale projects to refine your processes. Gradually scale up as you fine-tune your workflow and gain confidence in the capabilities of your 3D printing system.

Real-World Applications of Metal 3D Printing in Minnesota

In my years with GSC, I’ve observed a wide array of practical applications for metal 3D printers. One standout example is in the healthcare sector, where custom implants and prosthetics are crafted with unparalleled precision. These customized solutions significantly enhance patient outcomes, showcasing the tangible benefits of adopting this technology.

The aerospace industry is another early adopter. Companies use metal 3D printing to create complex, lightweight components that traditional methods can’t easily manufacture. The reduction in part weight translates to fuel savings and increased efficiency, critical metrics for aviation performance and sustainability.

In Minnesota’s thriving educational sector, institutions leverage 3D printing to enrich engineering curriculums. By providing students with hands-on experience, educational programs are aligning with industry needs, ensuring graduates are well-equipped for future challenges.

- Aerospace: Lightweight structural components

- Healthcare: Custom prosthetics and medical tools

- Automotive: Rapid prototyping and tooling

- Education: Enhanced learning experiences

How does metal 3D printing compare to traditional manufacturing methods in terms of cost-effectiveness and efficiency?

Metal 3D printing brings a distinct advantage in cost-effectiveness and efficiency, especially for complex and custom parts. Traditional manufacturing often involves expensive tooling and significant material waste, as everything must be perfectly precise from the outset. In contrast, 3D printing processes like selective laser melting or electron beam melting build components layer by layer, reducing material waste. This methodology not only saves on raw material costs but also minimizes the time-consuming steps of retooling and setup seen in conventional manufacturing. For industries undergoing rapid prototyping phases, such as aerospace and healthcare, this efficiency enables faster iterations and a quicker path to market. Imagine a scenario where a small batch of parts needs frequent modifications–3D printing can adapt without the high costs of retooling, providing both economic and time-saving benefits. Have you considered how the integration of this technology could enhance your specific production processes?

What role is Minnesota playing in advancing metal 3D printing technology, and how could this influence national and global trends?

Minnesota has positioned itself as a key player in the 3D printing revolution by fostering a robust ecosystem of innovation. With a history of heavy investment in high-tech industries and close collaboration between universities, research institutions, and manufacturing companies, Minnesota is pushing the boundaries of what metal 3D printing can achieve. This collaborative spirit contributes to significant advancements in the field, such as enhanced material properties and more efficient production processes. The state’s efforts don’t just influence local manufacturing; they set trends that influence national strategies and even global standards. When businesses adopt these breakthroughs, they gain a competitive edge. Have you thought about how regional advancements in Minnesota could provide insights or opportunities for your own organization’s strategies on a larger scale?

What are some common misconceptions about the reliability and durability of metal 3D-printed parts, and how are these being addressed?

One common misconception is that 3D-printed metal parts lack the durability and reliability of traditionally manufactured components. Initially, this concern was valid, as early-stage technologies struggled to match the strength of parts produced by traditional methods. However, recent advancements have significantly enhanced the layering precision and material properties, ensuring that 3D-printed parts can meet, if not exceed, industry standards. For instance, modern printers employ sophisticated powdered metals and controlled heating processes to achieve optimal part density and strength. Furthermore, rigorous testing and validation procedures have been put in place to assure quality standards are consistently met. So, while skepticism may still exist, the reality is that these parts are now being widely used in critical applications, such as in aircraft and medical devices. Have you experienced such skepticism, and how can addressing it help unlock new possibilities for your business?

Are there specific industries in Minnesota that are leading the charge in adopting metal 3D printing, and what applications are they focusing on?

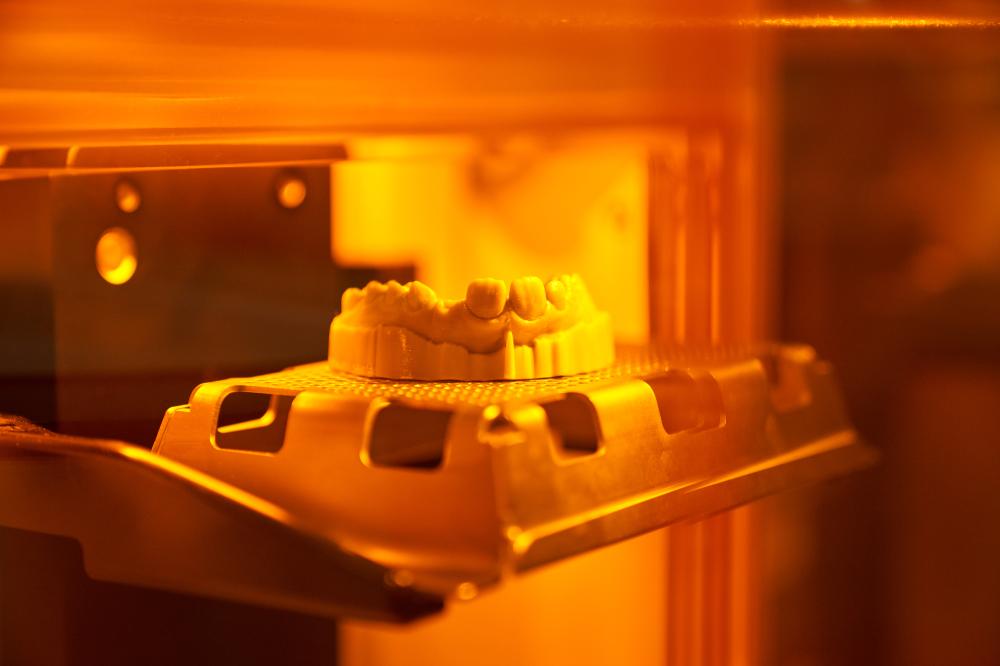

Within Minnesota, several industries are pioneering the adoption of metal 3D printing. Healthcare and aerospace sectors are notably at the forefront. In healthcare, custom prosthetics and dental implants are produced with high precision using 3D printing, significantly improving patient outcomes. The aerospace industry leverages 3D printing for crafting lightweight, durable components that contribute to fuel efficiency and performance. Automotive companies also benefit by using 3D printing for rapid prototyping, enabling faster design iterations. Academic institutions have not lagged behind either, as they incorporate this technology into curricula, offering practical learning environments that prepare students for future challenges. Have you ever considered how adopting 3D printing might open up new innovation avenues within your field?

What are the essential steps for a company looking to integrate metal 3D printers into their workflow successfully?

Successfully integrating metal 3D printers into your workflow requires a strategic approach. Start with a comprehensive assessment of your production goals and identify specific areas where 3D printing can offer distinct advantages over traditional methods. This could range from rapid prototyping to small-scale production runs. Next, it’s vital to choose the right technology that aligns with your needs. Not all 3D printers are created equal, so consult experts to ensure you select a model that fits your operational and financial constraints. Remember, training is crucial. Your team needs to understand and manage the new technology effectively, so invest in comprehensive training programs. Collaborate with material suppliers to secure high-quality metals, and begin with small-scale projects to refine your process. Don’t rush the scaling phase–each step is a learning opportunity that solidifies your confidence and competence in using this groundbreaking technology. What kind of challenges do you anticipate in your integration process, and how could expert guidance help mitigate them?

How is GSC uniquely positioned to support companies interested in implementing metal 3D printing solutions?

GSC is uniquely positioned to provide unparalleled support for companies looking to implement metal 3D printing solutions. With over 30 years of experience in 3D engineering, GSC offers a comprehensive suite of services that extend beyond just supplying the printers. We pride ourselves on becoming an extension of your team, offering technical support that ensures seamless integration of new technology into existing workflows. Our experts assist with everything from CAD software implementation to 3DEXPERIENCE solutions, helping you maximize your investment and productivity. Moreover, GSC provides training opportunities and events like SOLIDWORKS & 3DEXPERIENCE workshops to keep your team ahead of the industry curve. With our extensive network, from Wisconsin to California, personalized service is always within reach. How might leveraging GSC’s resources and expertise make a difference in your transition to 3D printing technology?