Markforged Illinois

Exploring the Benefits of Markforged Printing

- Cost-Effectiveness: By drastically reducing the cost of each part, companies can see a rapid return on investment.

- Time Efficiency: As lead times shrink, businesses can react swiftly to changing market demands.

- Material Versatility: From metals to composites, the range of materials available provides unparalleled flexibility.

With over 20 years in the field, I’ve observed the rapid adaptation industries have made to these technologies, paving the way for new business models and operational efficiencies.

Why Choose Markforged Illinois?

- Identify your specific needs and the parts that could benefit from on-demand production.

- Assess the potential cost savings with precise ROI calculations, considering the cost reductions in part production.

- Evaluate the impact on operations, considering the agility and customization capabilities of Markforged Illinois solutions.

For example, our client in the automotive sector reduced tooling lead times by 50%, enhancing their market responsiveness.

How Does Markforged Illinois Enhance Industrial Application?

- Tooling and Fixtures: Custom tools can be created rapidly, aligning with production schedules and quality demands.

- Prototyping: Engineers can iterate designs quickly, testing functional prototypes without the traditional wait times.

- End-use Parts: With materials that withstand demanding conditions, these printers deliver sustainable and reliable final products.

Each application leverages the strength and versatility of Markforged Illinois tools, showcasing their capacity to revolutionize industry standards.

What is the Impact of Markforged Illinois on Local Businesses?

“Implementing Markforged Illinois technology allowed us to cut overheads by 25% while maintaining a high level of precision in our parts.”

It’s this kind of innovation that fuels competitive advantage, enhancing the local economy and providing a platform for growth.

Innovative Approaches to Manufacturing

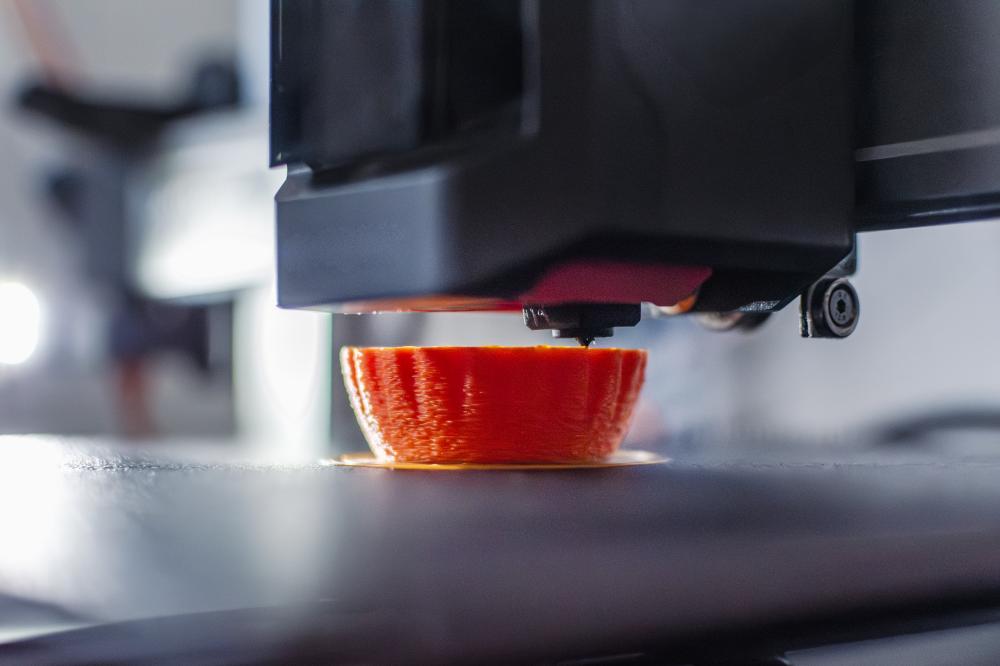

Using composite materials with continuous carbon fiber in production has allowed engineers to produce previously impossible geometries, challenging traditional manufacturing constraints.

Further, the integration of IoT with 3D printing ensures that production lines remain dynamic and responsive, promoting unparalleled customization options for clients.

What Qualifies as a Markforged Illinois Emergency?

Sudden machinery failure on the production line or unexpected high demands for specific parts that standard supply chains cannot meet rapidly.

In such cases, utilizing on-site 3D printing capabilities allows companies to produce critical parts within hours, minimizing downtime and maintaining operational continuity.

What are the core benefits of using Markforged solutions in Illinois?

Markforged offers several key benefits that are particularly relevant for businesses in Illinois. The primary advantages include cost-effectiveness, with significant reductions in the cost of each part produced. This translates to a faster return on investment, which is always appealing to any business. Additionally, the solutions boast incredible time efficiency. With reduced lead times, companies can adapt more swiftly to market changes. Moreover, the versatility of materials, ranging from metals to composites, supports numerous industrial applications. In my experience, working closely with clients at GSC, I’ve seen how these benefits transform operations, leading to streamlined processes and the exploration of new business models.

Why should a company consider adopting Markforged technology in Illinois?

When considering adopting Markforged technology, it’s important to focus on specific needs and the potential for on-demand production. I’ve seen companies achieve substantial cost savings by precisely calculating the ROI through reduced production costs. The agility and customization capabilities that Markforged solutions bring can also significantly impact operations. In a notable case, one of our automotive clients was able to reduce tooling lead times by 50%, dramatically improving their market responsiveness. If you’re looking at Markforged for your business, I recommend evaluating these factors to understand the tangible benefits it can offer.

How does Markforged enhance industrial applications specifically?

Markforged’s ability to produce strong, lightweight components is a game-changer for industries like aerospace and automotive. The technology facilitates rapid production of custom tools and fixtures, aligning with production schedules and meeting high-quality standards. Engineers can iterate quickly when prototyping, enabling innovation without traditional wait times. I recall a project where we helped a firm prototype a complex component in under a week, something previously unthinkable. The end-use parts produced are also highly reliable in demanding conditions, making these solutions ideal for maintaining industry standards while pushing boundaries. This adaptability has allowed many of our clients at GSC to stay ahead of their competitors.

What impact does Markforged have on local businesses in Illinois?

The impact on local businesses has been remarkable. Markforged provides new efficiencies and revenue opportunities. For instance, a local manufacturer cut overhead costs by 25% while maintaining precision thanks to Markforged technology. Such enhancements fuel competitive advantages and contribute to the local economy’s growth. I’ve witnessed clients leverage these innovations to explore new markets and optimize existing operations. Reflecting on this, it makes one wonder how further advancements in 3D printing could continue to revolutionize local industries. What potential applications could you see for your own business?

What innovative approaches does Markforged introduce to manufacturing?

Markforged has introduced some truly innovative strategies to manufacturing, particularly with the use of composite materials. By using continuous carbon fiber, engineers are now able to design and engineer geometries that were previously impossible, challenging traditional manufacturing constraints. The integration of IoT with 3D printing is another significant advancement, offering dynamic production lines with unparalleled customization options. These approaches promote a highly responsive manufacturing environment. At GSC, we’ve helped clients implement these technologies with astounding results, and I can confidently say it’s just the beginning. Could this be the direction of manufacturing evolution in your industry as well?

What constitutes an emergency when using Markforged technology?

An emergency involving Markforged technology typically occurs when there’s an urgent need for a solution due to unforeseen disruptions, such as sudden machinery failure or unexpectedly high demand for specific parts. In such scenarios, having on-site 3D printing capabilities allows companies to produce critical parts within hours, minimizing downtime and maintaining operational continuity. I’ve worked with clients who faced such challenges, and the ability to quickly print required components has saved them significant time and money. It’s always wise to consider how prepared your operation is for such potential emergencies. Do you have strategies in place to handle unexpected production halts?