Industrial 3D Printer Iowa

Industrial 3D Printing in Iowa: Exploring Opportunities

As technology advances, Industrial 3D Printer Iowa is becoming a buzzword for businesses looking to leverage additive manufacturing potential. Iowa, with its growing tech ecosystem, is poised to become a hub for industrial 3D printing solutions. The state is witnessing a convergence of innovation and traditional manufacturing, creating opportunities for entrepreneurs and established firms alike.

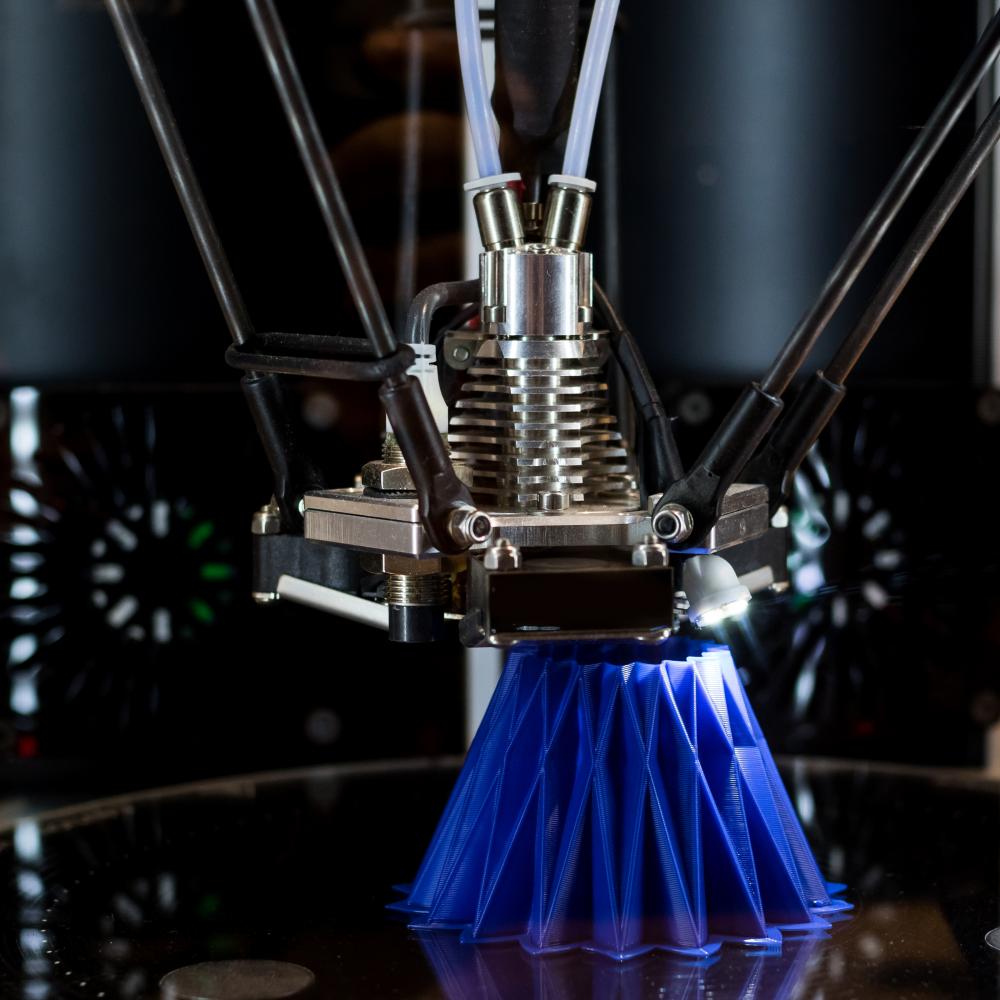

Industrial 3D printers have transformed the manufacturing landscape by streamlining production processes and enabling the creation of complex geometries with ease. Companies across Iowa are realizing the benefits of in-house production, reduced lead times, and material cost savings. As a professional with over 20 years in the industry, I’ve seen firsthand how businesses are integrating this technology to enhance production capabilities.

Iowa’s strategic location and infrastructure make it an ideal place for companies seeking to optimize supply chains using additive manufacturing. Industrial 3D Printer Iowa is not just reshaping local industries but also serving as a catalyst for economic growth in the region.

Benefits of Investing in Industrial 3D Printer Iowa

Integrating Industrial 3D Printer Iowa into your business model can yield numerous advantages. First, it allows for rapid prototyping, which accelerates product development cycles. This capability is crucial for companies needing to stay ahead in competitive markets. Additionally, 3D printing reduces waste, promoting sustainability–an essential aspect in today’s eco-conscious world.

With the ability to produce low-volume parts efficiently, businesses can cater to custom demands without incurring the high costs of traditional manufacturing setups. This flexibility is driving innovation across sectors such as aerospace, healthcare, and automotive industries. Iowa’s manufacturers are embracing this shift, using 3D printers to produce intricate components that were previously deemed impossible or impractical.

Moreover, the technology enables on-demand manufacturing, minimizing the need for inventory and warehousing. Companies can capitalize on this by offering personalized products, enhancing consumer satisfaction. Investing in Industrial 3D Printer Iowa is not only about keeping up with technology trends; it’s an investment in the future of manufacturing.

GSC Perspective on 3D Printing

At GSC, we’ve been at the forefront of 3D printing services for over three decades, providing clients with cutting-edge solutions tailored to their specific needs. Our experience in the industry has given us insights into the transformative power of Industrial 3D Printer Iowa.

We emphasize client collaboration, acting as an extension of their teams to ensure seamless integration of 3D tools into existing processes. From SOLIDWORKS 3D CAD to advanced simulation tools, our comprehensive suite of services equips businesses with the resources they need to thrive.

Our commitment to innovation is reflected in our product offerings, including the Markforged line of printers that provide unparalleled reliability and precision. We’re not just selling printers; we’re enabling a transformative experience for our clients, helping them to harness the full potential of additive manufacturing.

With locations throughout the Midwest, including Iowa, GSC is dedicated to providing personalized service and technical support that underscores our commitment to client success. We’ve cultivated a work environment that fosters creativity and growth, ensuring our team is as innovative as the solutions we provide.

What Are Common Questions About Industrial 3D Printer Iowa?

Industrial 3D Printer Iowa involves several considerations and queries that prospective users often have. One common question is: What materials can be used in industrial 3D printing? The range of materials is extensive, including plastics, metals, ceramics, and composites, each offering unique properties for different applications.

Another frequent inquiry is about the cost. While initial investments may seem high, the long-term savings on production costs, alongside the increased efficiency and capability it brings, often justify the expense. Companies also ask about the learning curve, which is generally less steep than anticipated, thanks to user-friendly interfaces and comprehensive training programs provided by suppliers like GSC.

Lastly, businesses want to know about scalability. Fortunately, industrial 3D printing scales well, from small-batch productions to much larger runs, allowing flexibility in meeting varied production needs.

Steps to Implement Industrial 3D Printing in Your Business

Implementing Industrial 3D Printer Iowa technology in your business can be a strategic move. Here are some steps to guide you:

- Assess Needs: Identify specific areas where 3D printing can add value to your operations.

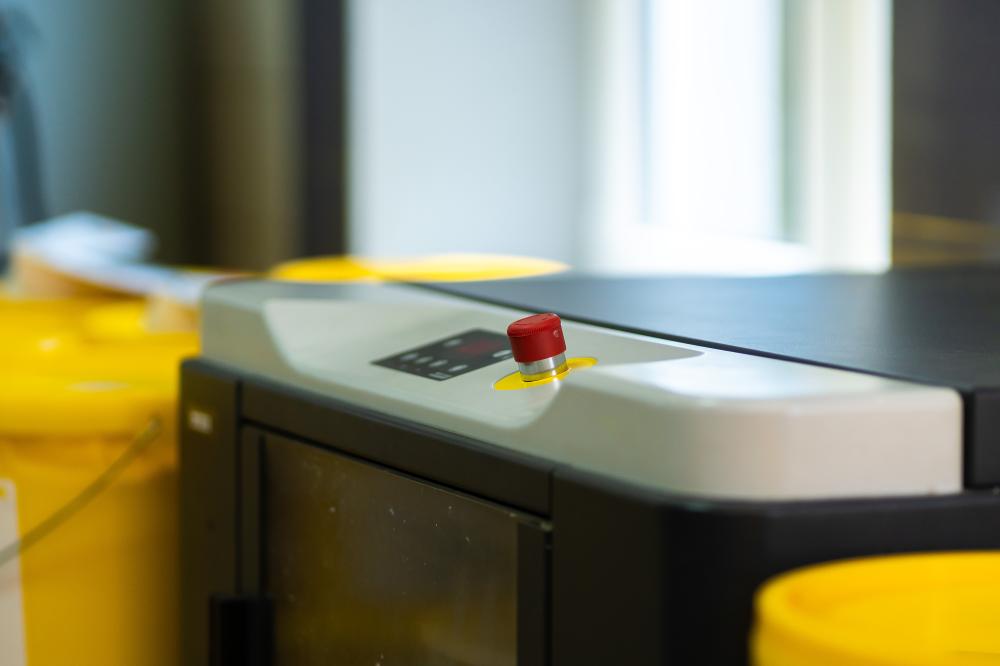

- Choose the Right Printer: Consult with experts to select a printer that matches your production requirements and budget.

- Train Your Team: Provide training to your staff to ensure they are comfortable operating the new equipment.

- Start Small: Pilot the technology with a few projects to refine workflows and optimize the integration process.

- Scale Up: Once successful, gradually expand the use of 3D printing to other areas of your production process.

Each step is crucial in ensuring a smooth transition to this innovative manufacturing approach, unlocking greater efficiency and potential for innovation.

How Industrial 3D Printer Iowa Is Impacting Local Industries

In Iowa, the impact of Industrial 3D Printer Iowa is profound. Local industries are experiencing a shift in how products are designed and manufactured, leading to a surge in creativity and innovation. Small and medium businesses now have the tools to compete on a global scale, thanks to the efficiencies offered by 3D printing technology.

The ability to produce prototypes rapidly allows companies to iterate and improve their designs quickly, reducing time to market. Additionally, industries such as healthcare are witnessing advancements in patient-specific solutions, improving treatment outcomes and patient experiences.

As more businesses in Iowa adopt Industrial 3D printing, the collaborative ecosystem strengthens, encouraging knowledge sharing and partnership development. This transformation is a testament to the state’s adaptability and foresight in embracing technology to drive economic growth and industry competitiveness.

Understanding the Benefits of Industrial 3D Printing in Iowa

Industrial 3D printing offers numerous benefits, especially for businesses in Iowa looking to innovate and streamline production. By integrating this technology, companies can significantly reduce lead times and material costs. For instance, consider an Iowa-based automotive supplier that recently adopted 3D printing for producing complex parts. They now enjoy the flexibility of customizing prototypes quickly, which has accelerated their development cycles and positioned them competitively in the market. While many still perceive the technology as expensive, the initial investment is often balanced by long-term savings and efficiency gains. Is your business ready to make this kind of leap?

Addressing Common Misconceptions About Industrial 3D Printing

One widespread misconception is that 3D printing is suitable only for prototyping. However, it’s increasingly viable for full-scale production, especially for customized and complex components. I recall speaking with a healthcare provider in Des Moines who was skeptical about using 3D printing for medical devices. After seeing the precision and reliability offered by a Markforged printer, they realized its potential for producing patient-specific items efficiently. With its scalability, industrial 3D printing can grow with your business needs, enabling not just innovation but also adaptability to changing market demands. What potential applications can you envision for your industry?

Choosing the Right Materials for Industrial 3D Printing

Industrial 3D printers can utilize a vast array of materials, from robust metals and versatile plastics to advanced composites. Each material brings unique properties that can support diverse applications. For instance, using metal 3D printers in Des Moines, businesses have been creating aerospace components that need to withstand high temperatures and stress. Selecting the right material is critical and often requires collaboration with technical experts to match your specific application needs and performance requirements. Have you considered how the choice of material could impact your product’s success?

Investing in Industrial 3D Printing: What to Consider

Investing in industrial 3D printing involves several considerations, including understanding your production volume and selecting a machine that aligns with your goals. At GSC, we’ve guided numerous businesses through this journey, often starting with a thorough needs assessment. Imagine a small manufacturer in Iowa that began with a desktop 3D printer to prototype consumer goods, eventually scaling to an industrial series for full production. Grasping the scale and scope of initial projects can help ensure that the investment aligns with strategic business growth. Are you ready to pivot your business model to incorporate cutting-edge manufacturing methods?

The Impact of Industrial 3D Printing on Iowa’s Economy

Industrial 3D printing is reshaping Iowa’s economic landscape by empowering local industries to compete globally. With faster prototyping capabilities, Iowa-based companies can innovate and respond to market demands swiftly. For example, a Waterloo-based startup leveraged 3D printing to disrupt the agricultural equipment sector by designing customizable parts. This flexibility not only boosts local manufacturing but also fosters a culture of innovation and collaboration among businesses. As such technologies advance, they also attract skilled talent to the region, further enhancing economic growth. How do you think your business could contribute to and benefit from this regional transformation?

Overcoming the Learning Curve in Industrial 3D Printing

The transition to industrial 3D printing can seem daunting, but support and training mitigate the challenges. At GSC, we emphasize comprehensive training programs to ensure a smooth adoption. I’ve worked with clients who initially faced technical challenges, but through tailored workshops and ongoing support, they quickly became proficient. The learning curve is often less steep than anticipated, thanks to user-friendly interfaces and robust support systems. As you contemplate this shift, consider how training and resources can empower your team. How might these resources change your team’s perspective on adopting new technologies?