Markforged 3D Printer Indiana

Advancements and Innovations in Markforged 3D Printing

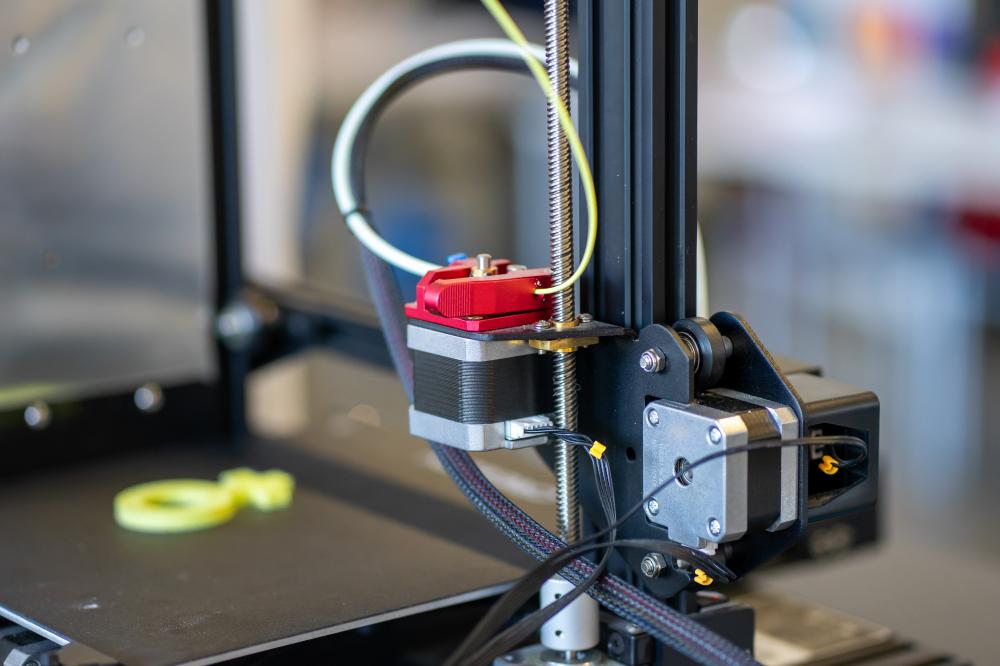

Over the last decade, 3D printing has transitioned from a niche hobby to an essential component of industrial manufacturing. The transformative capabilities of Markforged 3D printers have played a significant role in this evolution, especially in regions like Indiana, where manufacturing remains a vital industry. Markforged printers are recognized for their innovation in combining carbon fiber and metal materials, pushing the boundaries of what’s possible with additive manufacturing.

In Indiana, businesses are leveraging these advancements to produce stronger and lighter components, significantly reducing prototyping and production time. As industries strive for efficiency and cost-effectiveness, the integration of Markforged 3D printing solutions offers a competitive edge, especially in sectors like aerospace and automotive manufacturing, which are prominent in the state.

What Makes Markforged 3D Printers Unique?

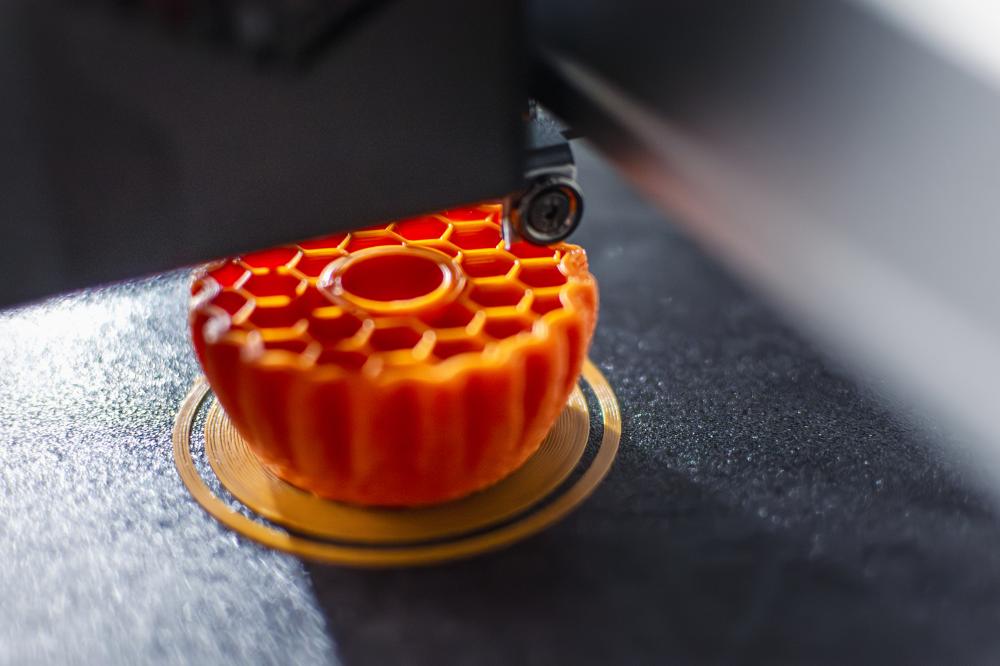

Markforged 3D printers stand out due to their ability to print with continuous fiber reinforcement, which enhances the strength of printed objects. This capability is particularly beneficial for creating functional prototypes and end-use parts that must withstand significant stress.

The technology employs a unique process called Continuous Fiber Fabrication (CFF) that embeds fibers like carbon, glass, or Kevlar into thermoplastic filaments during the printing process. This results in parts with properties often superior to traditional manufacturing without sacrificing design flexibility.

Moreover, the accessibility and intuitive software provided by Markforged make it an attractive option for businesses, large and small, looking to integrate 3D printing into their manufacturing processes. These benefits have been widely adopted by Indiana companies aiming to innovate and improve their production capabilities.

Integrating Markforged 3D Printers in Indiana’s Manufacturing Landscape

In Indiana, the integration of Markforged 3D printers has stimulated growth across various industries. Key sectors such as automotive, aerospace, and defense have taken advantage of these advanced additive manufacturing technologies to streamline their operations.

For instance, an Indiana-based automotive supplier was able to cut its prototyping time by 50% by using Markforged 3D printers, resulting in faster iterations and quicker time-to-market for new products. This kind of efficiency gain is a prime example of how Indiana companies are leveraging these technologies to maintain competitiveness.

Additionally, the collaboration between educational institutions and industry has fostered a new generation of engineers skilled in using 3D printing technologies. This initiative ensures a steady pipeline of talent to support the growing demand for advanced manufacturing in the region.

- Rapid prototyping and production

- Enhanced training programs

- Cross-industry collaboration

Benefits of Choosing Markforged 3D Printer Indiana

The advantages of using Markforged 3D printers are numerous, particularly for businesses in Indiana. The ability to produce lightweight yet robust parts allows companies to reduce material waste and consequently lower production costs. Additionally, rapid prototyping speeds up innovation cycles, helping manufacturers stay ahead in competitive markets.

The following steps outline how Indiana businesses can maximize the benefits of Markforged 3D printers:

- Identify components beneficial for 3D printing within your existing product line.

- Collaborate with 3D printing experts to assess material requirements and optimize designs for additive manufacturing.

- Implement training programs for staff to efficiently utilize the Markforged 3D printers.

- Regularly evaluate the performance of printed parts to ensure they meet industry standards.

Exploring Challenges and Overcoming Obstacles

While the adoption of Markforged 3D printers in Indiana presents numerous benefits, businesses may also face challenges. Initial setup costs, for instance, can be high, and there may be a learning curve associated with operating the new technology. However, these obstacles are surmountable with strategic planning and investment in training.

An example from my experience at GSC demonstrates how proper planning and execution can mitigate these challenges. By focusing on delivering comprehensive training programs and ongoing support, our clients have successfully integrated Markforged 3D printers into their operations, leading to a significant boost in production efficiency.

Ultimately, the successful adoption of Markforged technology hinges on a commitment to adapt and innovate, traits that Indiana’s manufacturing sector embodies fully.

Where Can You Get a Markforged 3D Printer in Indiana?

For those interested in acquiring a Markforged 3D printer in Indiana, it’s crucial to partner with a reliable provider that offers not only the printers but also the necessary support and training. As a trusted resource, GSC is dedicated to helping Indiana companies harness the full potential of these cutting-edge printers.

GSC provides tailored solutions to meet specific needs, ensuring that each client receives the best possible service and support to integrate 3D printing into their manufacturing processes. Our commitment to excellence and customer satisfaction has made us a preferred provider for Indiana businesses looking to innovate and thrive in the competitive marketplace.

What recent advancements have Markforged 3D printers brought to the manufacturing industry in Indiana?

Markforged 3D printers are at the forefront of innovation in manufacturing, particularly in Indiana where industries such as aerospace and automotive are key players. The ability to print using a blend of carbon fiber and metal has revolutionized how companies approach manufacturing, making components not only lighter but also much stronger. For Indiana businesses, this means drastically reduced prototyping and production times, as well as a notable decrease in material costs. Imagine an automotive supplier capable of slashing prototyping times by half–this isn’t just a hypothetical scenario; it’s a reality with Markforged technology. Such efficiency translates into faster product development and a stronger competitive stance in an ever-evolving market. Have you considered how integrating such technology might expedite your own production cycles?

What distinguishes Markforged 3D printers from others available in the market?

Markforged 3D printers shine in their ability to incorporate continuous fiber reinforcement, a feature that significantly enhances the strength of the printed parts. This is achieved through their unique Continuous Fiber Fabrication (CFF) process, which integrates fibers such as carbon, glass, or Kevlar directly into the thermoplastic filaments. This capability endows printed objects with remarkable durability, often surpassing traditional manufacturing methods without sacrificing design flexibility. Furthermore, the user-friendly software offered by Markforged makes it simple for any size business to integrate these cutting-edge printers into their workflow. Consider the possibility: with these printers, you could produce functional parts ready for end-use that withstand significant stress–how would this impact your current operations?

How are Markforged 3D printers being integrated into Indiana’s manufacturing landscape?

Indiana has embraced Markforged 3D printers as a transformative tool within sectors like automotive, aerospace, and defense. By utilizing these advanced additive manufacturing technologies, companies are streamlining operations and fostering significant growth. A local automotive supplier, for example, experienced a 50% reduction in prototyping time, allowing for faster product iterations and a shorter time-to-market. Such efficiency gains are crucial for maintaining competitiveness. This trend isn’t just about implementing technology; it’s about fostering collaboration between educational institutions and industries to cultivate a new generation of engineers skilled in these advanced techniques. Have you explored partnerships with educational institutions to leverage training opportunities in 3D printing technologies?

What benefits do Markforged 3D printers offer to businesses in Indiana specifically?

Businesses in Indiana benefit greatly from the lightweight and robust parts that Markforged 3D printers can produce. This ability results in reduced material waste and lower production costs, enhancing overall efficiency. Rapid prototyping accelerates innovation cycles, enabling manufacturers to remain competitive. To maximize these benefits, Indiana companies can identify components within their product lines that would profit from 3D printing, collaborate with experts to optimize designs and materials, and implement training programs to leverage these advanced printers effectively. What steps have you taken to ensure your workforce is trained to handle these cutting-edge technologies and adapt to evolving industry standards?

What challenges do Indiana businesses face when implementing Markforged 3D printers, and how can they overcome them?

While the advantages are clear, Indiana businesses face initial challenges such as high setup costs and a learning curve with Markforged 3D printers. However, strategic planning and investment in comprehensive training can mitigate these issues. For instance, at GSC, we’ve seen clients successfully integrate these printers into their operations by prioritizing in-depth training programs and ongoing support. This strategic focus not only smooths the transition but also boosts production efficiency. What specific strategies could you implement to ensure your team is fully prepared to utilize this technology effectively?

Where can businesses in Indiana acquire Markforged 3D printers, and what kind of support is available to them?

For Indiana companies interested in adopting Markforged 3D printers, partnering with a reliable provider like GSC is essential. We not only supply the printers but also offer comprehensive support and training to ensure successful integration into your processes. Our tailored solutions meet specific client needs, supporting innovation and competitiveness in the market. We pride ourselves on customer satisfaction and the ability to assist in leveraging these powerful tools. Have you considered reaching out for a consultation to explore how GSC can assist in enhancing your manufacturing capabilities with Markforged technology?