CNC Cam Software Wisconsin

The Importance of CNC Cam Software in Wisconsin

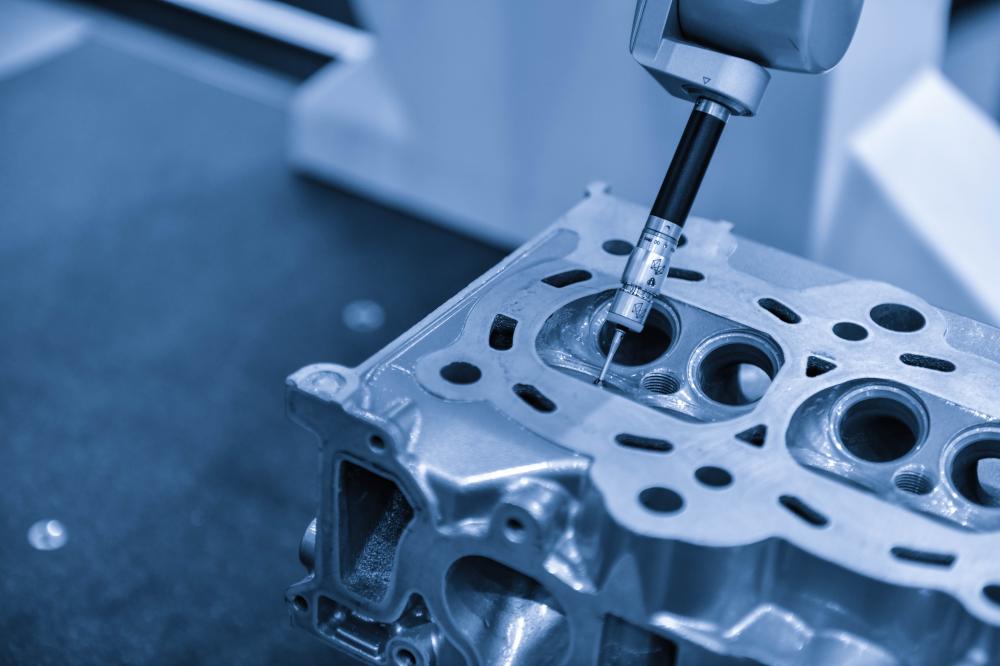

The landscape of manufacturing in Wisconsin is vibrant and ever-evolving. CNC Cam Software Wisconsin plays a critical role in ensuring that local industries remain competitive. By optimizing machining processes, this software helps businesses achieve higher levels of precision and efficiency. For over 30 years, GSC has been at the forefront, providing solutions that integrate seamlessly with tools like SOLIDWORKS. Our expertise in the industry ensures that we understand the intricacies involved in CNC machining.

Given the specific needs of Wisconsin’s industry, CNC Cam Software is more than just a tool; it’s a partner in production. It allows companies to innovate without compromising on quality. In cities like Milwaukee and Madison, where manufacturing is a staple, the ripple effect of effective software solutions is evident in product quality and operational efficiency. At GSC, our software solutions are tailored to the distinct needs of Wisconsin’s diverse manufacturing establishments.

Key Benefits of CNC Cam Software Wisconsin

CNC Cam Software Wisconsin delivers a multitude of benefits that can transform operations across industries:

- Precision: Achieve high levels of accuracy in machining tasks.

- Efficiency: Optimize workflow, reducing time and resource waste.

- Flexibility: Adapt to various machine setups and production needs seamlessly.

- Integration: Works cohesively with existing systems like SOLIDWORKS for streamlined operations.

These benefits not only improve overall performance but also enhance an organization’s ability to innovate and compete in a global market. The software empowers engineers and manufacturers to push boundaries, producing parts that meet exacting standards.

Choosing the Right CNC Cam Software for Your Needs

When selecting CNC Cam Software Wisconsin, consider how it integrates with existing systems and what specific functionalities your operations require. Key factors include:

Step-by-step considerations:

- Evaluate the compatibility with current CAD tools.

- Assess the level of support and training provided by the vendor.

- Consider the software’s scalability to accommodate future growth.

- Examine user reviews and case studies specific to your industry.

At GSC, we emphasize a consultative approach, ensuring that our clients choose solutions that not only meet immediate needs but also support long-term strategic goals. This careful selection process helps in achieving optimal results, be it in small-scale operations or large industrial setups.

What Qualifies as Essential CNC Cam Software Features?

Essential features of CNC Cam Software Wisconsin include seamless CAD integration, a user-friendly interface, robust simulation capabilities, and comprehensive post-processing options. These elements ensure efficient and accurate production.

The significance of these features lies in their ability to streamline operations and reduce errors. Simulation capabilities, for instance, allow engineers to visualize machining processes before actualization, thus minimizing costly mistakes. Similarly, post-processing options ensure compatibility with various machine types, enhancing flexibility.

Insights from 20+ Years of Experience in CNC Cam Software

Having worked for more than two decades in the field, I’ve witnessed firsthand the transformative power of CNC Cam Software Wisconsin. A notable experience was when a local manufacturer in Germantown dramatically reduced production time by integrating our software with their existing systems. The result was not just improved efficiency but also a significant boost in product quality.

An anecdote that stands out involves a team in Madison that leveraged our CNC Cam software to tackle a particularly challenging project. The success of this venture underscored the importance of software adaptability and support, which are key offerings at GSC. Our commitment to client success means that we’re not just software providers but partners in realizing the full potential of modern manufacturing.

What is the importance of CNC Cam Software in Wisconsin’s manufacturing sector?

CNC Cam Software is pivotal in Wisconsin’s manufacturing landscape because it enhances precision and efficiency, allowing businesses to remain competitive. The state’s industrial hubs like Milwaukee and Madison heavily rely on manufacturing, and effective software solutions like those provided by us at GSC ensure that local industries can innovate while maintaining high-quality standards. By seamlessly integrating with systems such as SOLIDWORKS, this software becomes more than just a tool; it partners in production, enabling innovation without compromising on quality.

What are the key benefits of using CNC Cam Software in Wisconsin?

The advantages of CNC Cam Software are multi-faceted. It vastly improves precision, ensuring high accuracy in machining tasks, and enhances efficiency by optimizing workflow and reducing resource waste. The software’s flexibility allows adaptation to various setups and production needs, while its integration capability with tools like SOLIDWORKS streamlines operations. These features not only enhance performance but also empower manufacturers to push boundaries and meet global standards. Imagine the difference a few percentage points in efficiency can make over a year across multiple production lines–it’s often substantial both in cost savings and quality improvement.

How do I choose the right CNC Cam Software for my needs?

Choosing the right CNC Cam Software involves several steps. Start by evaluating its compatibility with your existing CAD tools. Consider the level of support and training the vendor offers, as this can significantly affect your team’s ability to efficiently use the software. Scalability is another important factor to accommodate future growth. User reviews and industry-specific case studies can provide valuable insights. At GSC, we take a consultative approach to ensure our clients select solutions that not only meet their immediate needs but also align with their long-term strategic goals.

What qualifies as essential features in CNC Cam Software?

Essential features include seamless CAD integration, a user-friendly interface, robust simulation capabilities, and comprehensive post-processing options. These ensure that production is efficient and accurate. For instance, simulation capabilities allow engineers to visualize machining processes before actualization, minimizing costly errors. Likewise, post-processing options must be compatible with various machines to enhance flexibility. These features streamline operations and reduce the likelihood of mistakes, which can be both expensive and time-consuming to correct.

Can you share any personal experiences with CNC Cam Software that highlight its benefits?

Certainly! Reflecting on my two decades of experience, one memorable case involved a manufacturer in Germantown who integrated our software with their existing systems. This integration led to a dramatic reduction in production time and a significant boost in product quality. Another engaging story involved a team in Madison that used our CNC Cam software to tackle a particularly challenging project, highlighting the importance of adaptability and support–qualities we prioritize at GSC. Such experiences underscore our role not just as software providers, but as partners in realizing the full potential of modern manufacturing.

What are some common misconceptions about CNC Cam Software?

One common misconception is that CNC Cam Software is only for large enterprises with complex machining needs. In reality, businesses of all sizes can benefit from the precision and efficiency improvements it offers. Another misconception is that the software is too complex to implement. While there is a learning curve, especially for those new to the system, many vendors, including us at GSC, offer comprehensive training and support to ensure a smooth transition. It’s important for potential users to understand that the initial investment in training and integration pays off in significant long-term savings and productivity gains.

What are the future prospects for CNC Cam Software in Wisconsin?

The future prospects for CNC Cam Software in Wisconsin are promising, driven by the state’s robust manufacturing sector and ongoing technological advancements. As industries continue to embrace Industry 4.0, the demand for integrated, efficient, and adaptable software solutions like CNC Cam will only grow. At GSC, we’re poised to support this growth with our expertise, ensuring that Wisconsin manufacturers can leverage the latest technologies to maintain their competitive edge. This evolution invites a question: How will your company adapt to these changes, and what steps will you take to ensure you’re not left behind?