DELMIAWorks is an all-in-one ERP and MES solution for discrete manufacturers. It offers real-time visibility and control over production, inventory, finance, and quality, helping businesses streamline operations, boost efficiency, and scale with ease.

Boosting Production Performance with Real-Time Monitoring

To stay competitive, manufacturers need to speed up time-to-market, cut production costs, and raise product quality — all at once. One powerful way to do that? Real-time monitoring.

By tracking every machine and production cycle as it happens, manufacturers gain insights that improve efficiency and build resilience. With plants generating huge volumes of data daily, it’s critical to focus on the right signals. The most valuable insights come from real-time, context-aware data that directly supports decision-making.

When real-time monitoring is fully integrated across the design-to-manufacturing process, it can accelerate everything—from product development to delivery—while helping teams adapt quickly to challenges.

How Real-Time Monitoring Boosts Efficiency on the Shop Floor

Efficient and reliable machines are the backbone of modern manufacturing. When machines run smoothly, short-notice production is easier—and flexibility becomes a competitive edge.

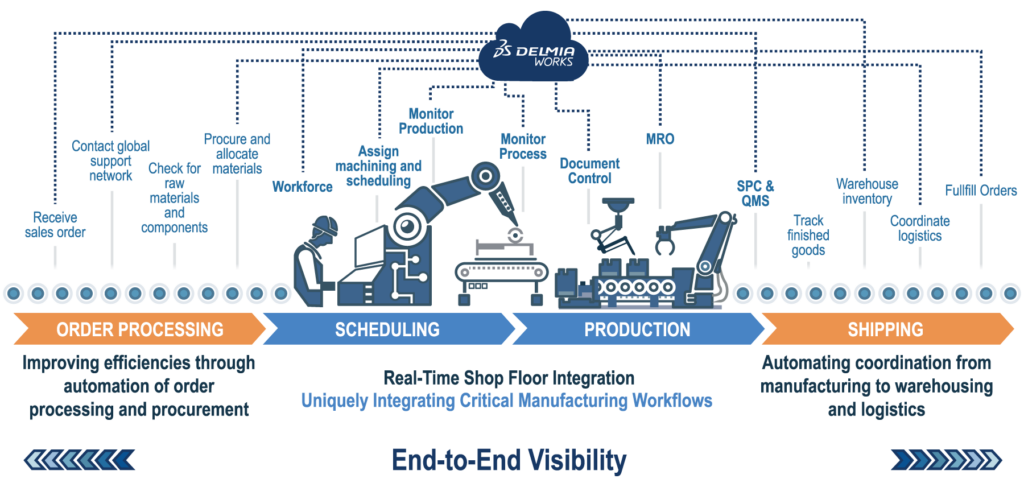

Real-time monitoring helps manufacturers keep everything in sync across the entire design-to-manufacturing process. From turning SOLIDWORKS designs into BOM estimates, to scheduling, inspection, quality control, and final fulfillment—real-time visibility ensures every step runs smoothly and stays aligned.

By connecting tools like CAD, CAM, ERP, MES, and quality systems, manufacturers can streamline production, lower costs, and still meet custom job demands. Since these systems operate at different speeds, real-time monitoring plays a key role in keeping everything synchronized and on schedule.

What’s working for manufacturers using this approach?

- Track real-time performance with measurable benchmarks

- Keep operations connected through centralized monitoring

- Optimize machinery by adjusting performance plans on the fly

- Align systems and workflows to improve output and product quality

Start with a Baseline: Real-Time Monitoring for Measurable Performance

Just like a fitness plan needs a starting point, manufacturers need a clear baseline to improve machine performance. Real-time monitoring provides that foundation—offering the data needed to build performance plans that actually deliver results.

By tracking machines continuously, manufacturers can drive steady improvements and stay resilient even in uncertain times.

A recent survey found:

- 81% of manufacturers say real-time monitoring is improving their business

- In industries like plastics, 87% call it essential

- 63% expect better tracking of machine performance, scrap, downtime, and utilization across different production runs

Real-time monitoring isn’t just helpful—it’s becoming a must-have for smarter, more responsive manufacturing.

Why Real-Time Monitoring Is the Glue of Modern Manufacturing

Real-time monitoring plays a crucial role in unifying the different parts of the manufacturing process. It connects engineering, quality, and production teams around a shared product data model—enabling better collaboration from design all the way to final output.

By feeding live data from machines back to these teams, real-time monitoring helps assess manufacturability, quality, and scalability for every product. This feedback loop improves decision-making, extends machine life, and drives more agile product development.

For example, insights into things like Mean Time Between Failures (MTBF) let teams fine-tune designs for both performance and reliability. The result? Fewer production errors, higher yield rates, and a more profitable, responsive manufacturing process.

Fine-Tuning Performance Plans with Real-Time Monitoring

Real-time monitoring is a powerful foundation for building smarter, more efficient design-to-manufacturing strategies. Here are three ways it drives performance:

- Faster Prototyping and Problem-Solving

By combining real-time monitoring with tools like 3D printing and CAM software, manufacturers can quickly move from digital model to prototype to production. A marine plastics manufacturer, for example, uses this approach to cut hours—and costs—by catching issues early and speeding up time-to-market. - Supporting Demand Before Products Ship

With real-time data, production planners can optimize workflows for new products even before they hit the factory floor. One carbon fiber OEM uses rendered product images during pre-production to help customers plan marketing and sales efforts—adding value well ahead of delivery. - Smarter Customization with CPQ

Real-time insights show which product configurations are most efficient and profitable to build. BMW’s Mini Cooper customization model is a great example—real-time data helps synchronize everything from design to final assembly, enabling higher-margin, made-to-order products at scale.

Building a Machinery Performance Plan That Delivers

Real-time monitoring gives manufacturers the data they need to improve machine health, boost production stability, and stay compliant with calibration standards. By tracking performance at the machine level, it’s easier to reduce quality variation and extend the life of expensive equipment.

This visibility also helps assign the right technicians to the right machines and optimize scheduling based on each machine’s “fitness level.” With real-time insights, manufacturers can fine-tune production plans for better efficiency and output.

Think of it like starting a fitness journey for your shop floor. Many manufacturers already have performance goals in place—the key is turning that data into action and measurable results.

Making Machines Agile: Aligning Performance with Design-to-Manufacturing

When manufacturers actively manage machine performance with a detailed fitness plan, they unlock the ability to move faster and take on more complex projects. Real-time insight into the speed, scale, and reliability of each machine brings greater agility across design, engineering, quality, and production.

The payoff? Faster product development timelines and fewer costly errors. Teams can better predict how machines will handle new requirements—helping smooth everything from early design through final assembly.

With clear data on improved yield rates, teams also gain confidence to accelerate testing and production cycles. And when every system in the manufacturing process runs at its own pace, real-time monitoring and machine fitness plans help keep everything in sync—making concurrency possible, and speed sustainable.

Bringing It All Together

Manufacturers see real results—faster development, better quality, and higher yields—when they bring all their systems together under a unified design-to-manufacturing approach. From simulation and CAM to inspection and ERP, the key is keeping everything connected and in sync.

Real-time monitoring makes that possible. It provides the data and coordination needed to align tools, teams, and timelines—so manufacturers can innovate faster, reduce costs, and deliver with confidence.

By working from a shared data foundation, teams can turn SOLIDWORKS designs into finished products more efficiently than ever—no guesswork, no delays, just smarter manufacturing.

Share

Meet the Author