3D Printing

How Leading Medical Device Manufacturers Harness 3D Printing Technology

Innovation in healthcare is undergoing a profound transformation, with 3D printing emerging as a cornerstone technology reshaping the landscape of medical device manufacturing. From prosthetics and implants to surgical instruments…

Read MoreFX10 – The Most Versatile Tool for Your Factory Floor

In the rapidly evolving landscape of modern manufacturing, technological advancements continue to shape the way companies operate, and one such groundbreaking innovation at the forefront is the Markforged FX10. This…

Read MoreHellermannTyton Boosts Efficiency and Cuts Costs with Markforged

Learn how HellermannTyton’s Automation Design Engineer, Amy Vasey, helped introduce and implement 3D printing in their automation department, cutting costs and boosting efficiency. Discover how they overcame initial challenges and proved the viability of 3D printing for replacing machined parts on end-of-arm tools.

Read More3D Printing Plastic Parts & Products

The integration of 3D printing technology has been a transformative force, particularly in the production of plastic parts and products. The advent of 3D printing has revolutionized traditional manufacturing processes,…

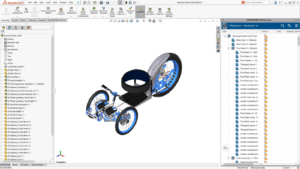

Read MoreStrategic Year-End Spending for Engineering, IT, and Operations Departments

Maximize year-end budget with strategic investments: SOLIDWORKS for efficient design and Markforged 3D printers for rapid, high-strength part production.

Read MoreTransforming Robotic End of Arm Tooling with 3D Printing

3D printing technology has changed manufacturing. Read why incorporating 3D-printed robotic EOAT can be a game-changer for companies.

Read MoreThe Role of Robotic End Effectors and 3D Printing in Modern Manufacturing

In the fast lane of manufacturing, innovation isn’t just a buzzword – it’s the ultimate differentiator between leaders and followers. One such innovation that’s making waves in the industry is…

Read MorePrint at the Point of Need: How 3D Printing Reduces Reliance on Outsourced Manufacturing Aid Components

In the realm of manufacturing, the production process often relies on various aids such as jigs, fixtures, and specialized tools to ensure efficiency, accuracy, and quality. Traditionally, manufacturers would outsource…

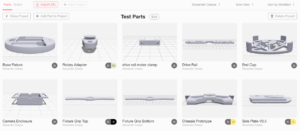

Read MoreEnabling On-Demand Low Volume Part Production from a Digital Inventory

Traditionally, manufacturing has been associated with mass production, where large quantities of identical parts are produced to meet market demands. However, a paradigm shift has occurred with the advent of…

Read MoreSupercharging Manufacturing Setup: 3D Printing’s Role in Streamlining Production Equipment Tooling and R&D

In the realm of manufacturing, setting up production equipment and fine-tuning the manufacturing process has traditionally been a time-consuming and resource-intensive endeavor. However, with the emergence of 3D printing technology,…

Read MoreRethinking Product Development with 3D Printing Technology

In recent years, the world of product development has been revolutionized by the emergence of 3D printing technology. Also known as additive manufacturing, 3D printing has become a game-changer for…

Read MoreEmbracing Innovation: How Manufacturing Leaders Implement 3D Printing in their Manufacturing Processes

In today’s rapidly evolving business landscape, manufacturing leaders constantly seek innovative ways to enhance their processes, increase efficiency, and stay ahead of the competition. One such innovation that has gained…

Read More