What is SOLIDWORKS Plastics?

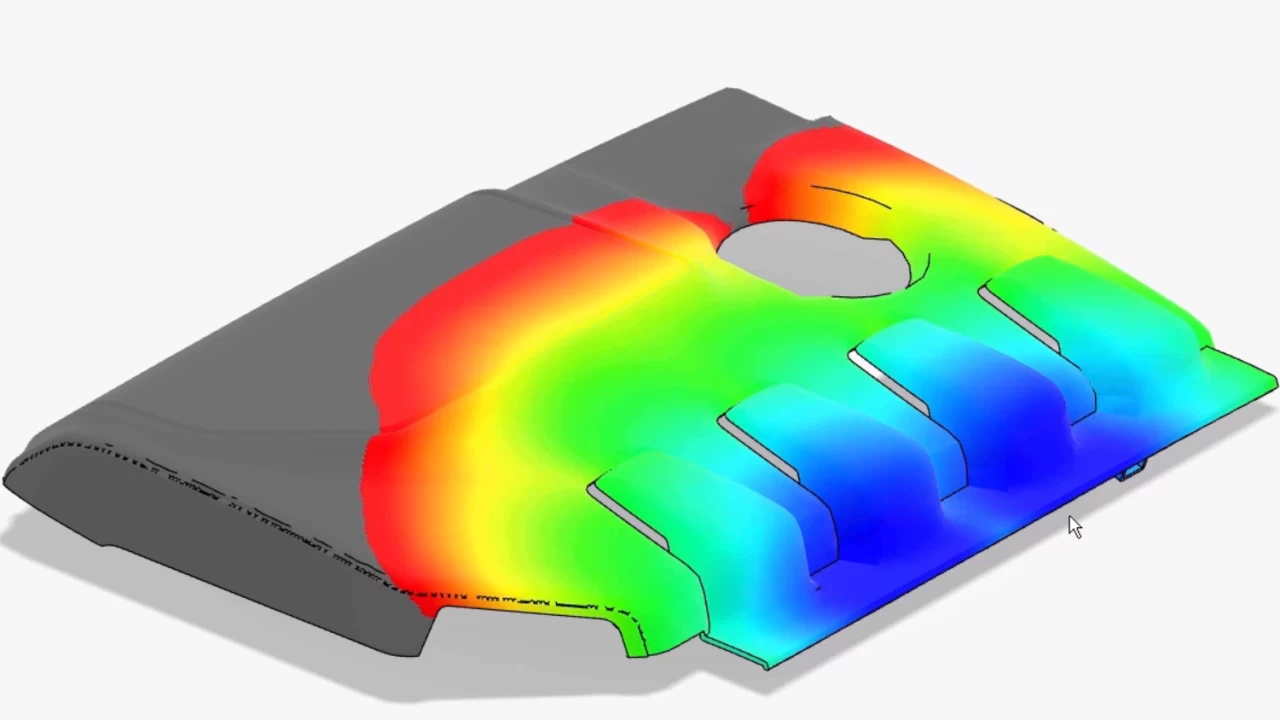

SOLIDWORKS Plastics delivers easy-to-use simulation for analyzing plastic parts and injection molds. It simulates how melted plastic flows during the injection molding process to predict manufacturing-related defects, allowing quick evaluation of part manufacturability during the design process.

For companies that design plastic parts or injection molds, SOLIDWORKS Plastics helps users predict and avoid manufacturing defects during the earliest stages of part and mold design, eliminating costly mold rework, improving part quality, and decreasing time to market.

SOLIDWORKS Plastics Packages

SOLDIDWORKS Plastics Standard

For plastics part designers, optimize parts in the early stages of design.

- Modify designs at the same time you optimize for form, fit, and function

- Fully embedded within SOLIDWORKS CAD environment

- Easy to learn and use

SOLIDWORKS Plastics Professional

Designers and injection mold makers gain an accurate, easy-to-use method for optimization. Includes Standard capabilities.

- Quickly create single-cavity, multi-cavity, and family mold layouts, including sprues, runners, and gates

- Balance runner systems and estimate cycle time, clamp tonnage, and shot size

- Optimize feed system design and avoid costly rework

SOLIDWORKS Plastics Premium

Allow CAE analysts and mold designers to analyze mold cooling line layouts and predict molded part warpage. Includes Professional plus advanced simulation functionality.

- Optimize cooling system design to minimize cycle times

- Design simple or complex mold cooling line layouts

- Optimize part mold design, material selection and processing parameters to reduce warpage

3DEXPERIENCE

SIMULIA

What is SIMULIA?

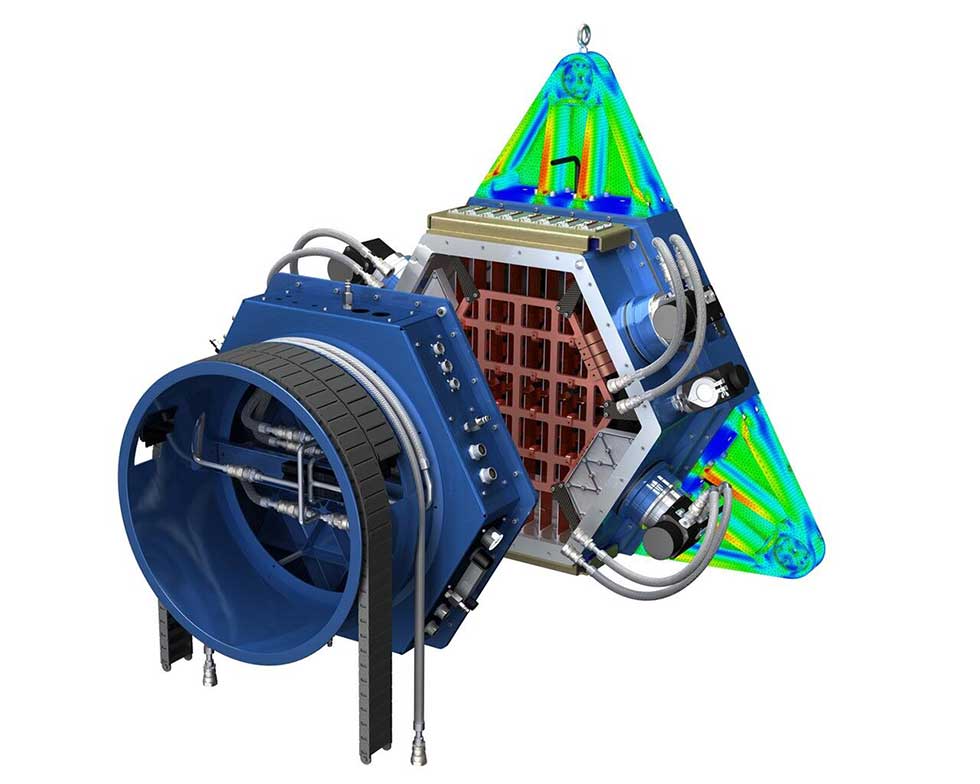

Powered by the 3DEXPERIENCE platform, SIMULIA delivers realistic simulation applications that enable users to reveal the world we live in. SIMULIA applications accelerate the process of evaluating the performance, reliability and safety of materials and products before committing to physical prototypes.

Plastic Injection Engineer

Plastic Injection Engineer brings easy-to-use injection molding simulation directly to the designers of plastic parts and injection molds. It simulates how melted plastic flows during the injection molding process to predict manufacturing-related defects on plastic parts.

Features:

- Validate plastic part and mold tooling designs for manufacturability and quality

- Predict common molding defects

- Evaluate the effectiveness of mold cooling system designs

- Apply advanced structural capabilities available in the 3DEXPERIENCE Platform

- Links to Process Apps (DOE) and Structures Apps (multiscale modeling)

Markforged

Additive Manufacturing

Simulation with Markforged 3D Printing

With Markforged Simulation, FEA is now easy and accurate. Simulate the strength and stiffness of a part printed with user-defined settings. This new software considers all parameters of the part and determines a part’s factor of safety and deflection before printing.