What is SOLIDWORKS CAM and CAMWorks?

Computer-aided manufacturing, or CAM, is a software used to control CNC machine hardware during manufacturing processes. This automation process is designed to hasten the production of products, parts or workpieces in a wide range of industries.

CAM/CNC software also works with computer-aided design (CAD) to achieve distinctive product requirements. It crafts designs from scratch and gives the machine step-by-step instructions on creating a masterpiece.

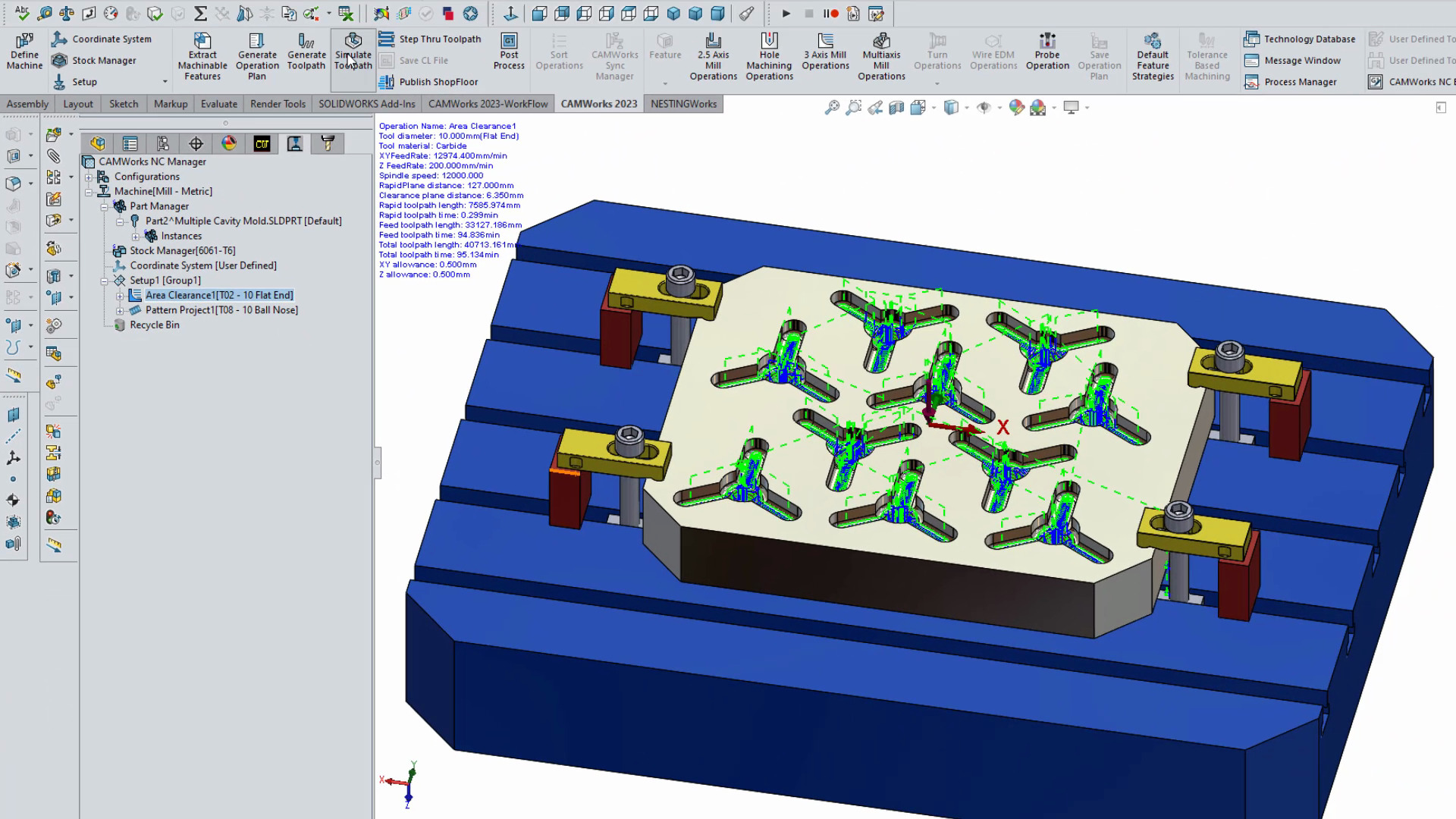

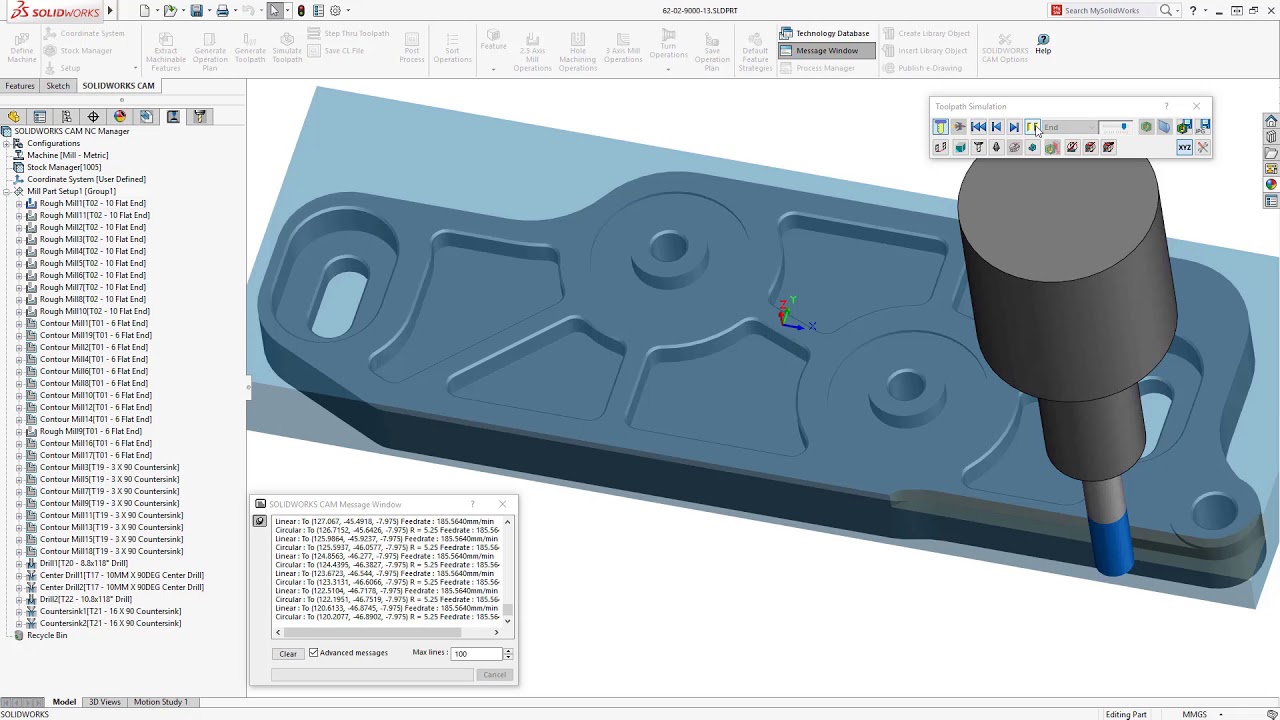

SOLIDWORKS CAM and CAMWorks are fully embedded within your SOLIDWORKS CAD system. Users can go directly from CAD to CAM without sending their part to different software. With CAM Data stored within the model, any modifications made to the part or assembly will automatically update the CAM toolpaths and G-code.

CAM Packages

What's New in CAMWorks 2025

- Wire EDM Premium

- Euler Angles Method for 5 Axis Rotary (3+2) Milling

- Machine Cavities with VoluMill

- Support for Tapered and Neck Shank Type Tools

- Option to Define Height of 2.5 Axis Milling Islands

SOLIDWORKS CAM

Rules-based machining follows your company’s best practices established through past programming. Couple this with Automatic Feature Recognition, and your business can automatically apply standard strategies to estimate machining time and setups required.

Find the Best Fit

Get the function you need in your budget.

CASE STUDY: Medical Device Manufacturer Saved 100+ Programming Hours with CAMWorks

There's no time to waste when you’re developing products to fight cancer. dotDecimal is a company that provides radiation therapy devices. CAMWorks' intelligent machining automated their processes, saving them hundreds of programming hours. After switching to CAMWorks, dotDecimal saw:

- 99.6% on-time delivery within 24 hours

- 85-90% automated product design and machining

- 100s of CNC programming hours saved

Advantages of CNC Software in Manufacturing

Using CNC software in manufacturing, engineering and even design offers many perks compared to manual operation. We've highlighted some advantages below:

- Quick project turnaround: Integrating CAM plus CAD with your CNC machines will speed up production. The programs make it easy for manufacturers to receive design models and other vital information from clients faster. Plus, CNC software enables machines to quickly complete prototype simulations, conduct test runs and create the final product.

- Better productivity: The advancements in CNC software technology have brought us lightning-speed machines that run on minimal cycles. That means tools and parts won't break down often, so we can maximize the machine's potential to the fullest. In addition, CAD/CAM improves the work quality by simulating toolpaths and allowing for continuous tool engagement.

- No mistakes: Advanced simulations are used in the manufacturing industry to inspect machine processes and detect errors. They let handlers foresee tool problems or collisions and get ahead of them. As a result, mistakes won't be made, and there'll be minimal machine tool repairs.

- Reduced wastage: When mistakes are eliminated, waste will follow suit. Computer-aided machining can therefore create "perfect products" the first time around. Consequently, there'll be no costly material waste during production.

- Mitigate human error: CAD minimizes human errors in design. The software saves a customer's design ideas, and its editing tools provide for modifications before production begins. This program generally doesn't allow errors (like humans would) to slip through.

- Greater accuracy: CAM delivers high accuracy each time, whether in small projects or large-scale production. Each product will be the same no matter the number of items made.

CAM FEATURES GLOSSARY

Learn about milling, turning, and G-code simulation.