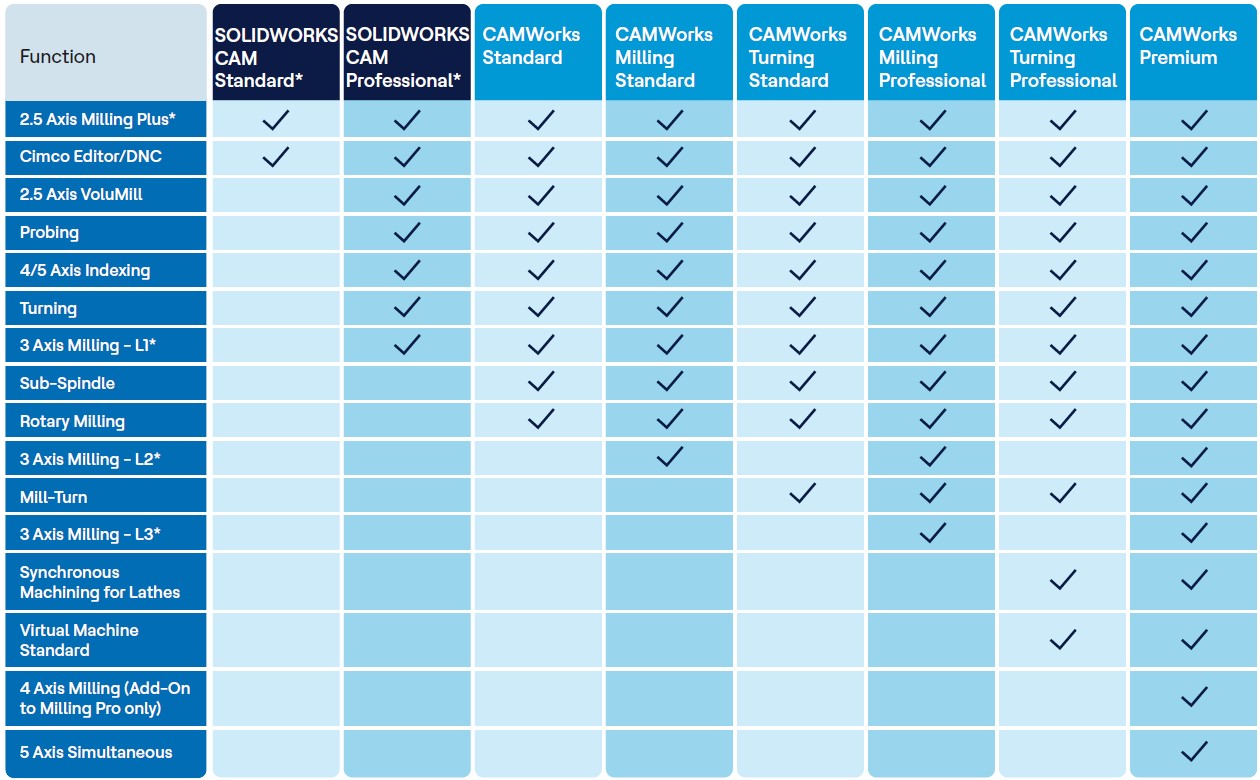

CAM Professional

Rules-based machining with increased programming capabilities.

SOLIDWORKS CAM Professional builds on the capabilities of SOLIDWORKS CAM Standard to increase programming capabilities. Professional incorporates many time-saving tools to maximize your ROI, including Volumill high-speed machining and 2-axis turning operations.

Capabilities Overview

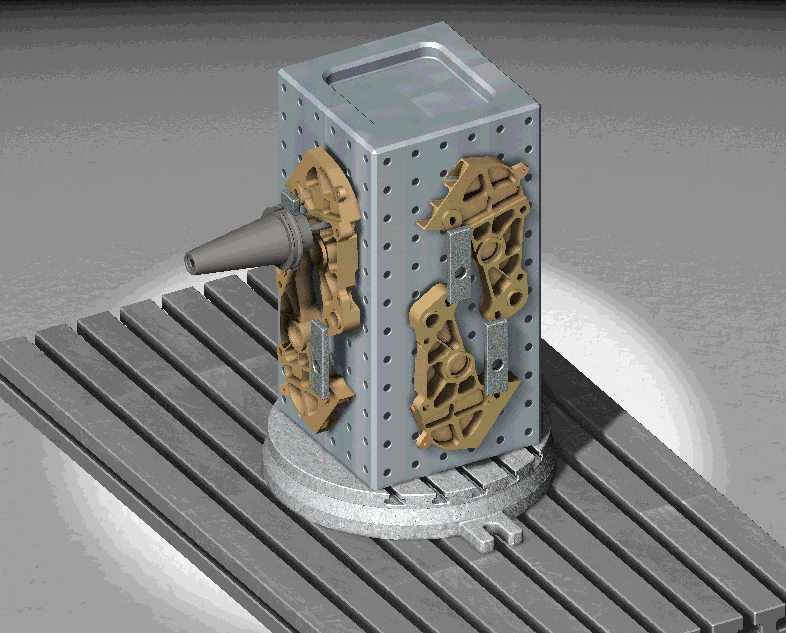

- Assembly Machining: Easily define multiple parts and fixtures, ensuring proper collision avoidance.

- Turning: Single turret turning is supported. Users can also take advantage of Automatic Feature Recognition, Knowledge-based Machining, and configurations; 2 Axis Turning.

- 4th and 5th- axis pre-positioning is supported, allowing for fewer setups while performing 2.5- axis milling operations.

- CIMCO Editor

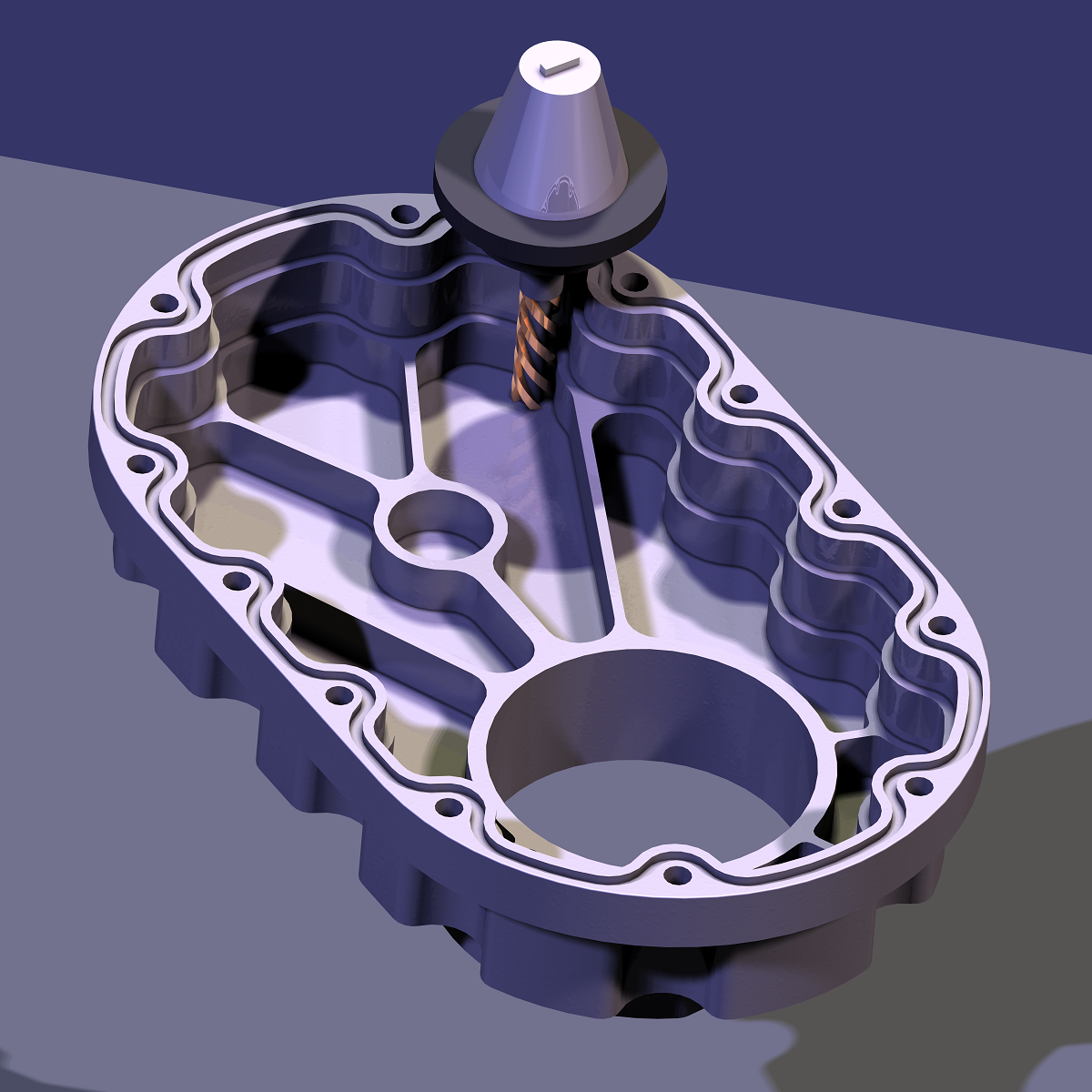

- High-Speed Machining: SOLIDWORKS CAM Professional uses VoluMill intelligent toolpaths which offers:

- 50% to 80% reductions in machining cycle times.

- Up to 75% savings on cutting tool costs.

- Reduced wear and tear on equipment due to smoother transitions in toolpaths.

SOLIDWORKS CAM combines design and manufacturing in one application with an easy-to-use interface. Rules Based machining and Automatic Feature Recognition result in easy-to-learn, yet fast and powerful CAM.

CAM Standard

Rules-based machining without leaving SOLIDWORKS.

SOLIDWORKS CAM Standard allows users to quickly program individual parts without leaving the SOLIDWORKS 3D CAD environment. This entry-level offering is included for any customer currently on subscription running 2018 or newer. You have full access to defining rules within SOLIDWORKS CAM to create and build to company standards. Powerful tools allow you to perform 2.5-axis milling operations, which is ideal for holes, pockets, and any feature with vertical sidewalls.

Capabilities Overview

- Recognition of any updated geometry as the model changes.

- Assign machining strategies based on recognized features.

- Update machining strategies if a design’s tolerance changes.

- Establish part setups and catching design errors to optimize manufacturability.

- Quote estimates quickly using Automatic Feature Recognition.

- Edit post-processors and back plot programs, using included tools, to ensure the code works right the first time, every time.

- 2.5 Axis Milling

- CIMCO Editor

CAM Features Glossary

Learn about milling, turning, and G-code simulation.

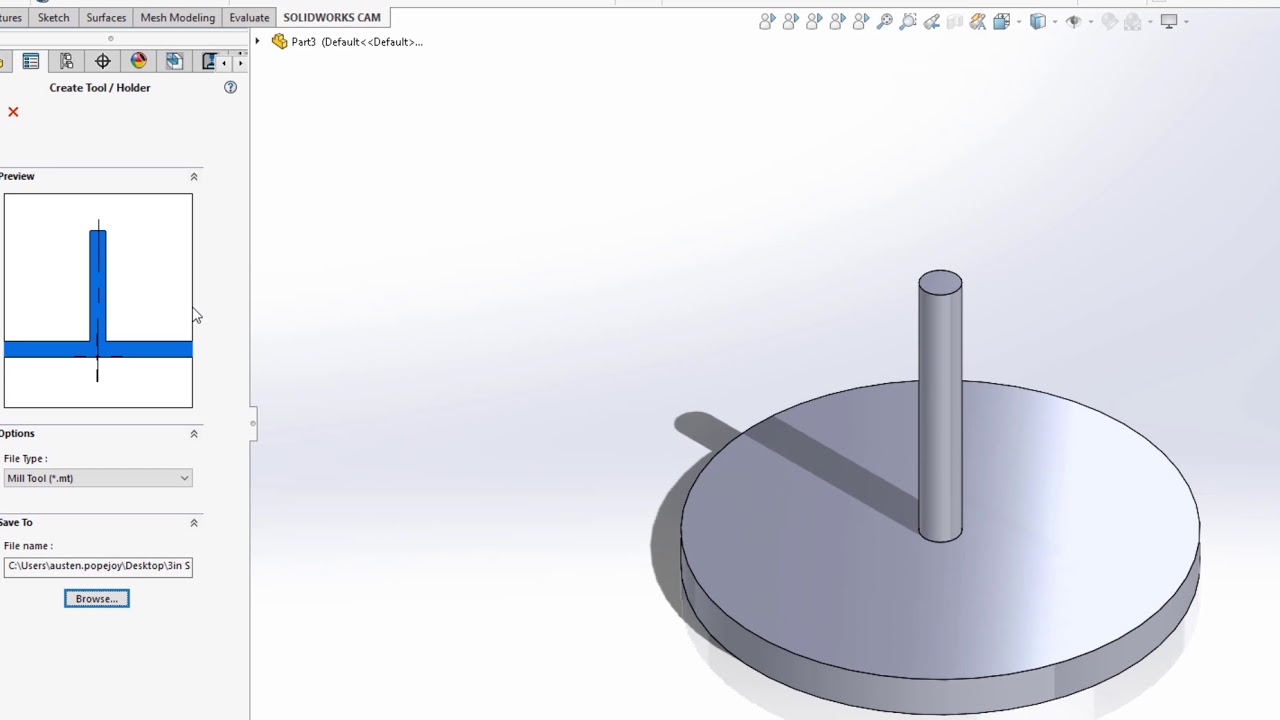

Learn how to create a custom tool in this quick tutorial. To get started, your sketch must be on the front plane with a vertical line of revolution and everything within the sketch must be to the right and above the origin.