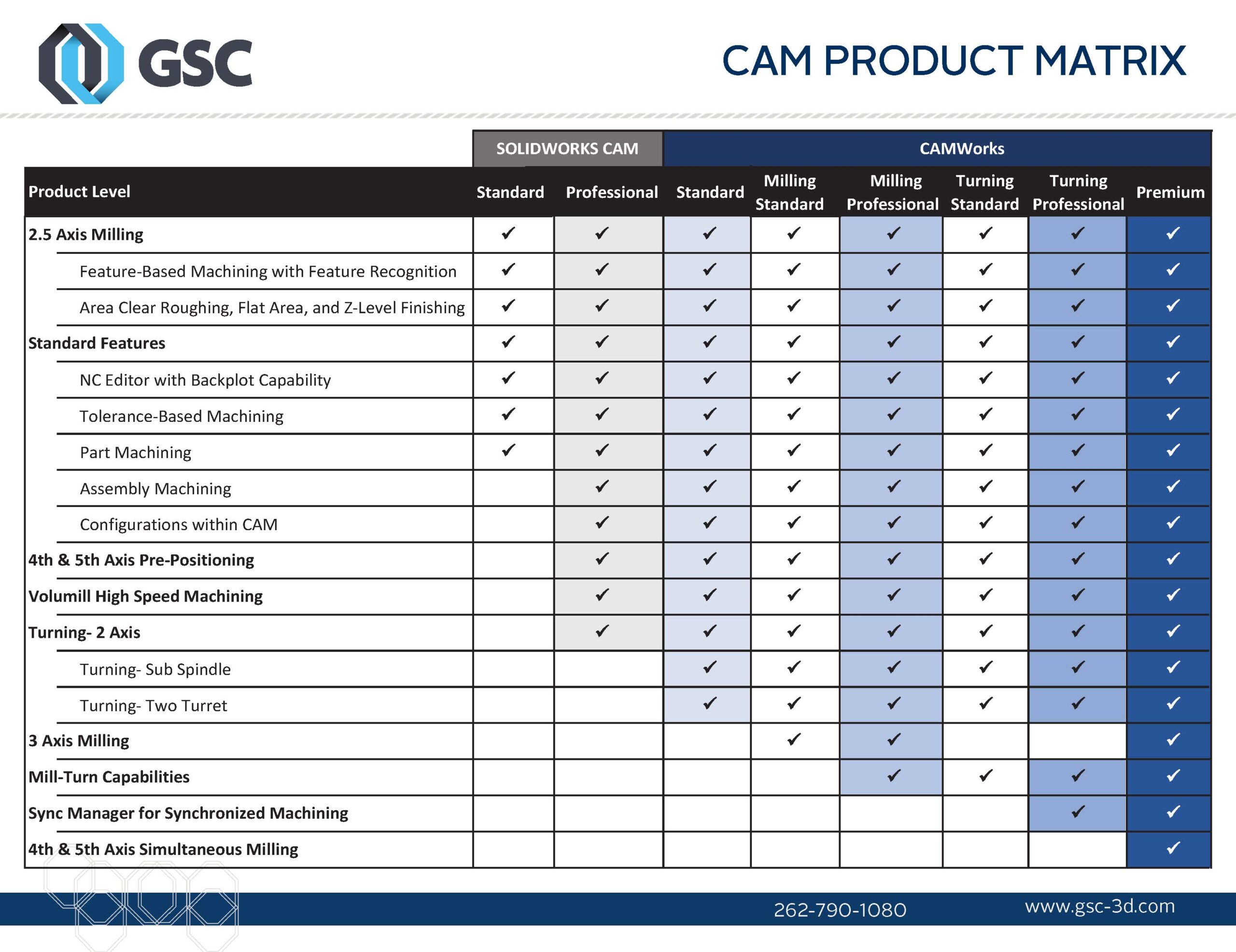

CAMWORKS PREMIUM

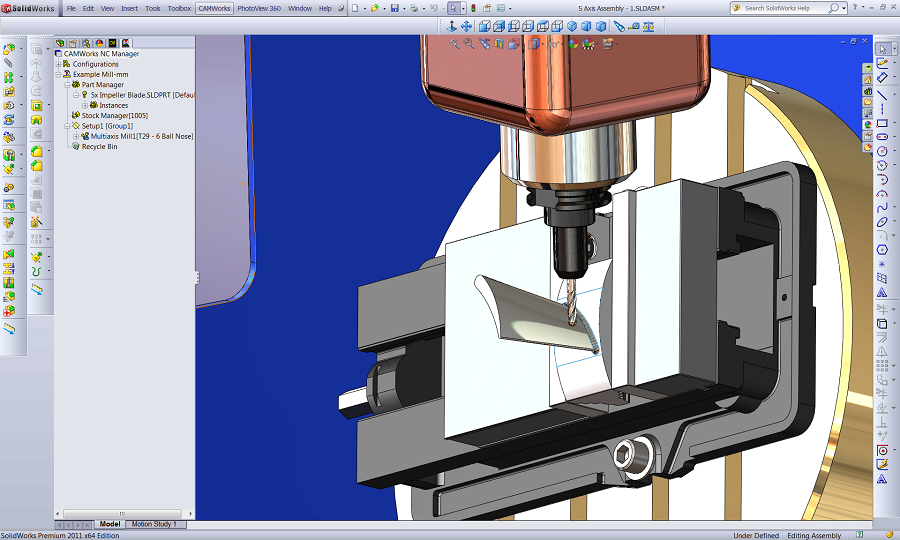

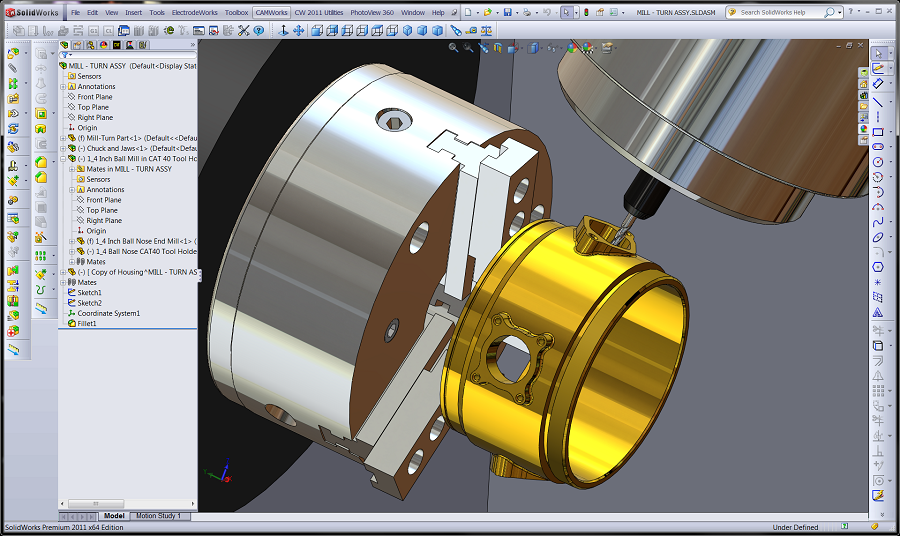

The ultimate machining bundle, CAMWorks Premium offers full 5 axis milling control. Feature-based and knowledge-based machining, simultaneous milling (2.5 through 5 axis) and mill-turn abilities deliver a highly efficient experience. CAMWorks Premium gives you the most capable CAM programming package, all within the familiar SOLIDWORKS environment.

- 2.5 Axis, 3 Axis (with undercutting), 4th Axis, and 5th Axis Milling

- Synchronous Machining, CIMCO Editor, & Virtual Machine Standard

- 4th & 5th Pre-Positioning

- 4th Axis Wrapped

- 2 Axis Turning, Volumill, & Mill-Turn

CAMWORKS STANDARD

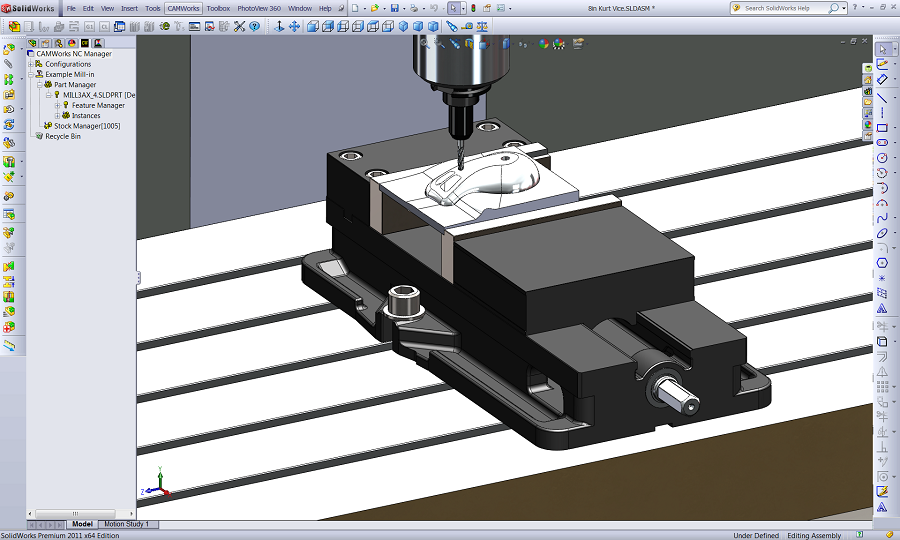

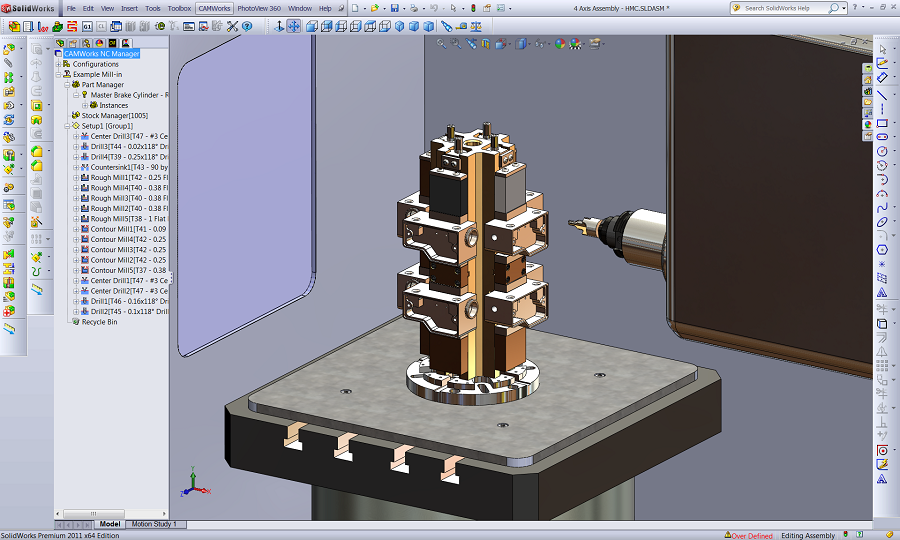

Assembly machining, 4 and 5 axis indexing, rotary milling, and more await in this CNC programming option for SOLIDWORKS. Get the essentials you need to machine quickly. CAMWorks Standard takes SOLIDWORKS CAM Professional’s potent capabilities and adds 4-axis wrapped milling and sub-spindle control for lathes.

- 2.5 Axis Milling & 2 Axis Turning

- 4th & 5th Pre-Positioning

- 4th Axis Wrapped

- Volumill, Sub-Spindle

- CIMCO Editor

Milling Professional

Fully integrated with SOLIDWORKS, Milling Professional is a CNC programming solution where you can high-speed machine. For the shop that needs the ultimate in milling capabilities, CAMWorks Milling Professional adds undercutting capabilities and Mill-Turn programming for an unbeatable combo.

- 2.5 Axis, 3 Axis (with undercutting), & 4th Axis Milling

- 4th & 5th Pre-Positioning, 4th Axis Wrapped

- 2 Axis Turning, Sub-Spindle

- Volumill, CIMCO Editor

Turning Professional

The most capable turning package on the market, CAMWorks Turning Professional features synchronous machining through the Sync Manager application, giving you the highest available throughput for your machines. For the ultimate in g-code simulation, Virtual Machine Standard is included as well.

- 2.5 Axis Milling, 2 Axis Turning, & Mill-Turn

- 4th & 5th Pre-Positioning, 4th Axis Wrapped

- Synchronous Machining, Virtual Machine Standard

- Volumill, Sub-Spindle, CIMCO Editor

Features

Additional Modules

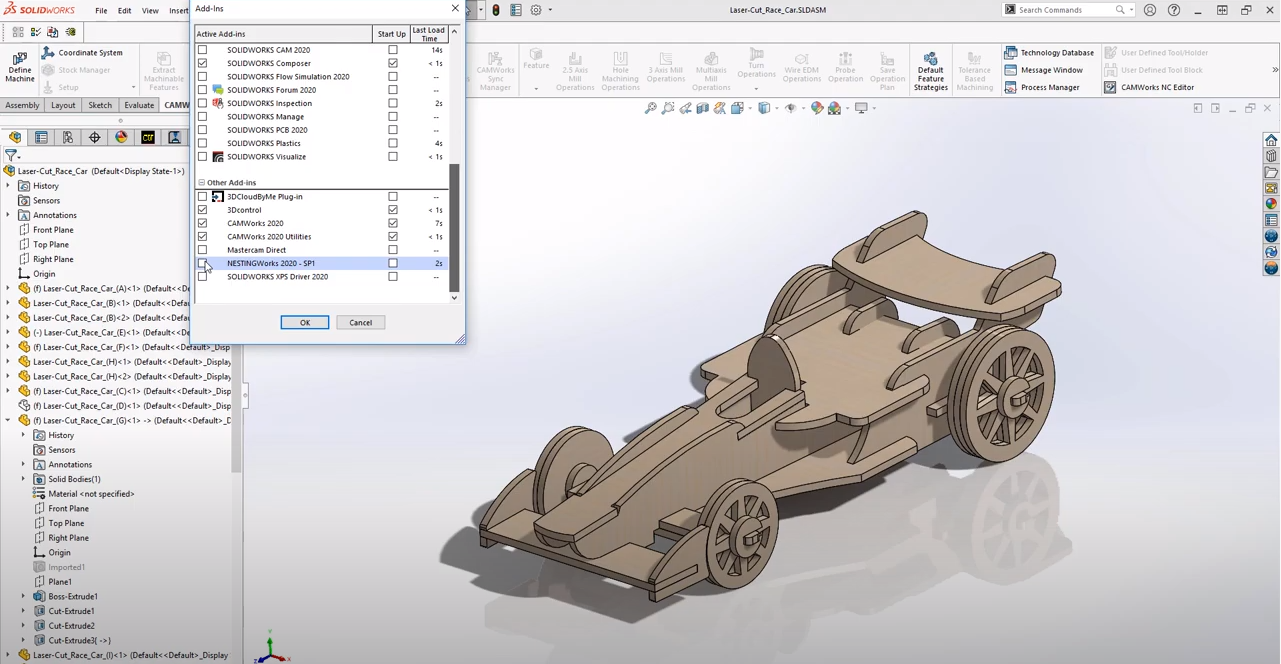

NESTINGWorks

Optimize sheet metal and flat stock designs, and smoothly transition from design to manufacturing for those same products. Using true-shape nesting, NestingWorks quickly guarantees you get the most from your available resources. NestingWorks is the perfect complement to any laser, waterjet, or router operations and can generate DXF or SOLIDWORKS assemblies for maximum flexibility.

CAMWorks ShopFloor

An industry first, CAMWorks ShopFloor gives machine operators the tools and visuals they're looking for to perform their jobs as efficiently as possible. ShopFloor combines setup sheets, simulation, and program management into a single file – accessible from nearly any device.

Wire EDM

CAMWorks EDM module was designed to be the only one you'll ever need. It can be added to any CAM package and is compatible with 2-axis and 4-axis operations. Using the same familiar fully-integrated interface as the other CAM packages, the EDM module utilizes Automatic Feature Recognition and the Knowledge-Based Machining to minimize the time spent programming and maximize throughput.

Learn more in a quick Intro to EDM Programming webinar.

Virtual Machine Standard

Verify G-code with one click. Simulating is directly available and ensures heightened precision and accuracy.

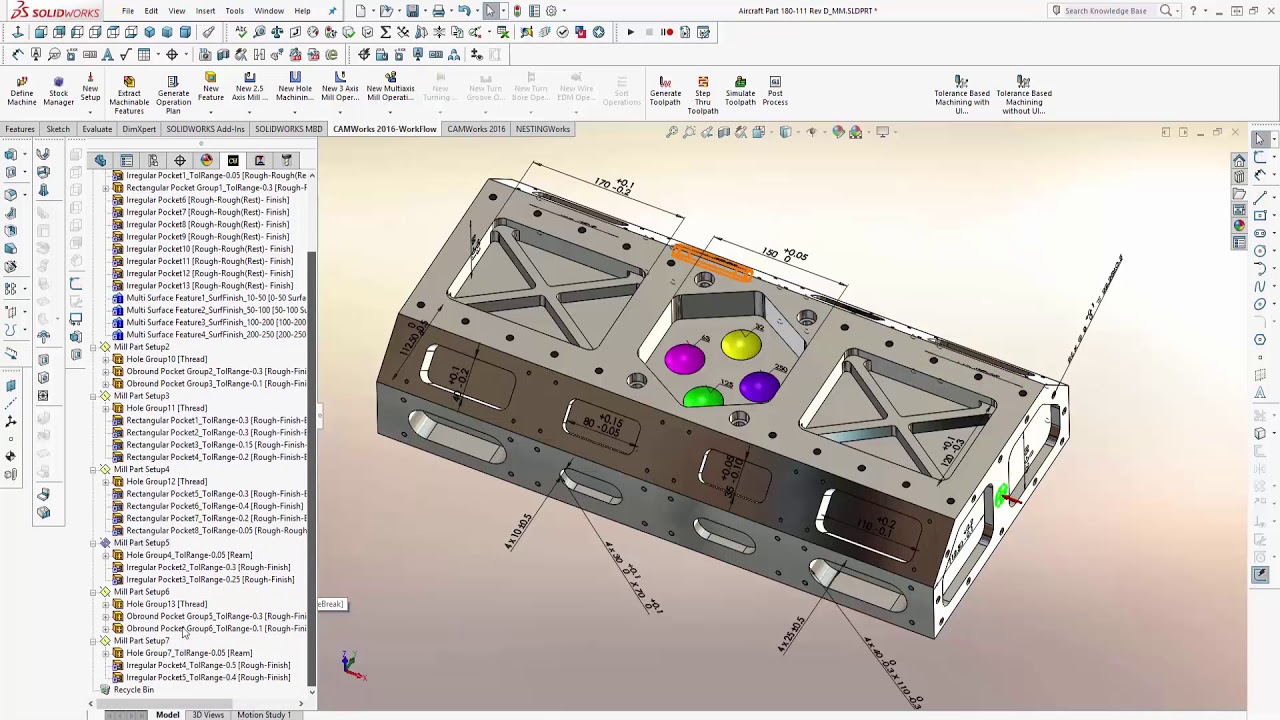

TOLERANCE BASED MACHINING

CAMWorks is a feature-based CAM software designed to boost CNC machining efficiency by incorporating top-notch technologies and customizable automation tools. With the latest 'Machine to the Mean' feature, CAMWorks resolves the age-old challenge of reconciling design practices and manufacturing requirements for tolerance parts based on fit, form, and function versus machining geometry based on mean dimensions and tolerances.

CAMWorks Shopfloor

CAMWorks ShopFloor makes all the manufacturing data available to the shop floor in a digital format, under one single interface.

- 3D Viewing of the Part and Assembly Model of the Setup

- Rotate, Zoom, Pan and Section View the Model

- View, Search and Filter MBD & PMI Data

- Take Linear, Radial, Angular, and Area Measurements

- Digital Setup Sheets & Tool Lists

- Step-Through Simulation for Each Operation or the Entire Program

- Full Toolpath Simulation

- Robust CNC Editor with Back-plotting

CAM Features Glossary

Learn about milling, turning, and G-code simulation.

Introduction to NESTINGWorks in CAMWorks

Here's a helpful intro to NESTINGWorks if you've never used it before! NESTINGWorks is an add-on module in the CAMWorks realm of products, closely related to SOLIDWORKS. In fact, it lives within the SOLIDWORKS environment and has a similar, clean interface.

You can do things like - Sheetmetal for unbending parts before nesting.

We start a new nesting job on an assembly, and go to the nesting job wizard. NESTINGWorks will find the optimal placement for you.

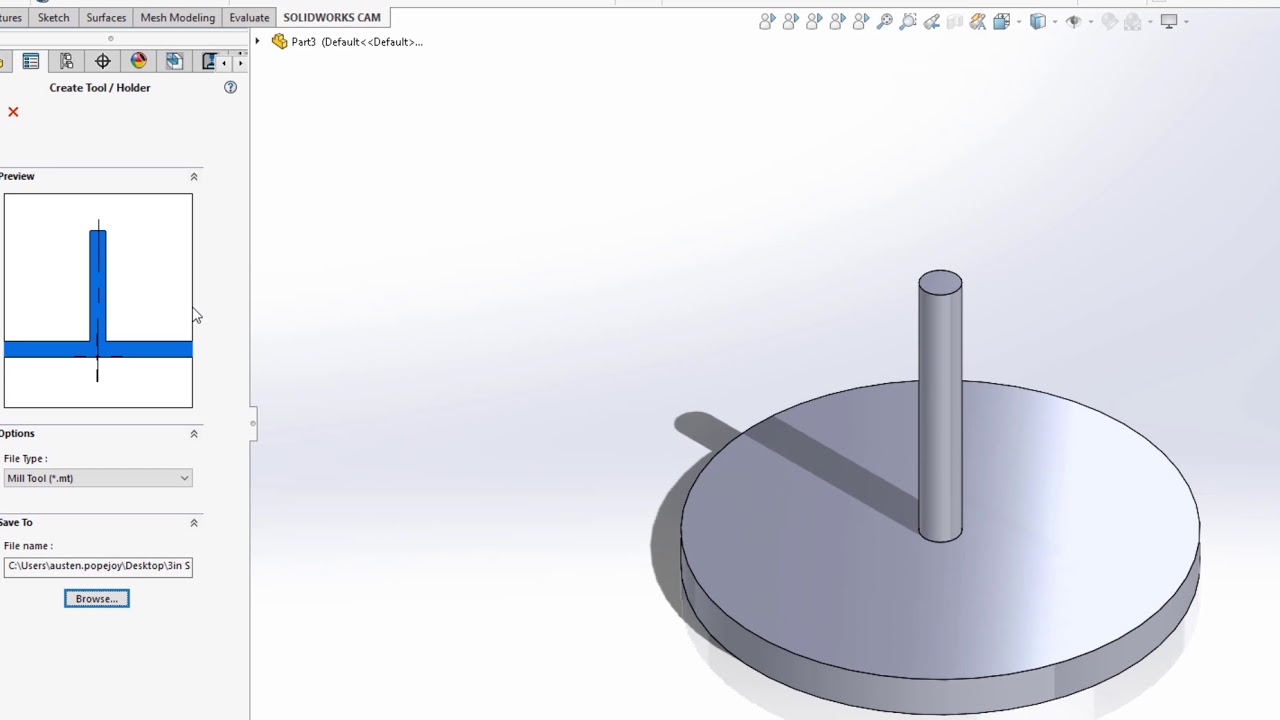

Creating a Custom Tool Within SOLIDWORKS CAM or CAMWorks

Learn how to create a custom tool in this quick How-To tutorial, applicable for SOLIDWORKS CAM or CAMWorks. Follow step by step to implement this handy technique for yourself. To get started, your sketch must be on the front plane with a vertical line of revolution and everything within the sketch must be to the right and above the origin.