September is Simulation Month

Welcome to Simulation Month!

Webinars

September 29 – Topology Optimization – Register

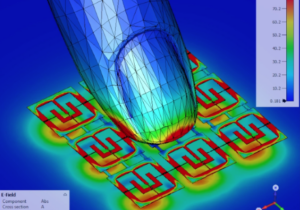

Target Your Specific Needs with CFD Analysis

Our Simulation Engineering Consulting team specializes in forms of CFD testing.

With our CFD analysis capabilities, we can simulate liquid and gas flow in real world conditions, run “what if” scenarios, and quickly analyze the effects of fluid flow, heat transfer, and related forces on immersed or surrounding components.

Fluids of interest for analysis range from air, water, liquid chemicals, and gases, to others such as plastic melts.

Our CFD Analysis can target your specific needs through a variety of techniques using SOLIDWORKS Simulation, SIMULIA, and/or Abaqus software. Our team of Simulation Design Engineers save time and can share a wide range of experience and apply it to your product design. Areas of expertise range from:

- Radiation heat transfer analysis between different temperature surfaces. Need solar radiation calculated? Our experts can help. Need conduction and convection heat transfer? We're here to assist.

- Internal flow analysis of liquids and gases through common elements such as valves, regulators, and ducts.

- Rotating reference frame analysis for understanding complex rotational flows inside turbo machinery.

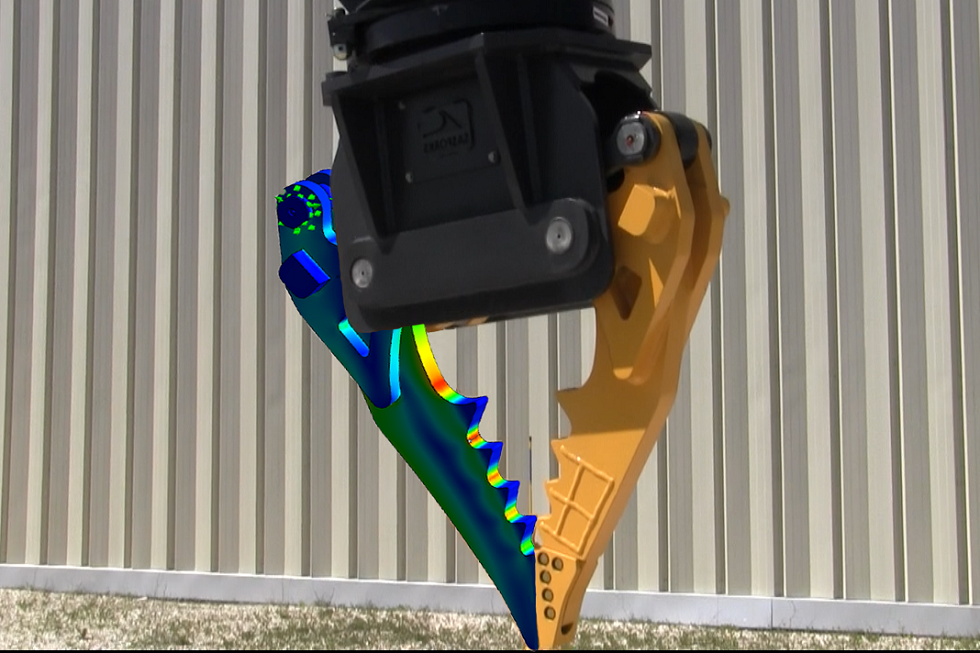

Advanced Validation Testing & Tools

GSC offers comprehensive and sophisticated Finite Element Analysis (FEA) to improve your products by:

- Studying the performance of your designs for excessive deflections and stresses under dynamic loads.

- Performing nonlinear analysis, including impact, on plastics, rubbers, polymers, and foam.

- Conducting contact analysis coupled with nonlinear materials.

- Evaluating the behavior of composite materials.