industrial 3d printer – Resources

Industrial 3D Printer – Resources

Top Industrial 3D Printer Options for 2025

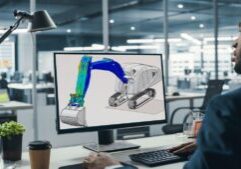

Modern manufacturing environments are undergoing a rapid transformation, driven by the convergence of advanced design software and sophisticated additive manufacturing hardware. At the center of this evolution is the role of a certified solidworks reseller, who acts as a strategic partner for companies looking to integrate digital design with physical production. By bridging the gap between Computer-Aided Design (CAD) and the factory floor, these experts help organizations select the right Industrial 3D Printer to streamline their workflows. Whether a firm is in aerospace, automotive, or industrial equipment, understanding how to navigate the technical landscape of additive systems is essential for maintaining a competitive edge in 2025 and beyond.

Critical Considerations for Selecting an Industrial 3D Printer

Choosing the right equipment requires a deep dive into specific production goals and technical requirements. One of the primary factors to consider when buying an industrial 3D printer is the intended build volume. Manufacturers must assess the maximum dimensions of the parts they intend to produce, as well as the throughput required for their specific business model. A larger build plate allows for the nested printing of multiple small components or the creation of large-scale prototypes in a single pass, reducing the need for post-process assembly.

Beyond size, print resolution and accuracy are essentials that cannot be overlooked. For industries like electronics or medical device manufacturing, the ability to maintain tight tolerances and achieve smooth surface finishes is paramount. An Industrial 3D Printer must be able to deliver repeatable results across every print cycle. This reliability is often what separates professional-grade systems from entry-level hardware. Reliability ensures that the digital model created in SOLIDWORKS translates perfectly into a physical object, minimizing waste and maximizing the efficiency of the manufacturing systems integration process.

Material Versatility and Advanced Multi-Material Processing

The diversity of materials available today has fundamentally changed how engineers approach product development. When asking what materials can industrial 3D printers handle, the answer now spans everything from high-performance thermoplastics to advanced alloys. For many specialized applications, a composite 3d printer is the ideal choice. These machines use continuous fiber reinforcement—such as carbon fiber, fiberglass, or Kevlar—to create parts that are as strong as aluminum but significantly lighter. This is a game-changer for producing custom jigs, fixtures, and end-use tooling that must withstand significant mechanical stress.

In addition to polymers and composites, the rise of the metal 3d printer has opened new doors for functional prototyping and low-volume production. These systems utilize metal powder or bound metal filament to create dense, high-strength components in materials like stainless steel, tool steel, and Inconel. By integrating these capabilities into a standard workflow, manufacturers can bypass traditional machining bottlenecks. This material flexibility allows a business to pivot quickly between different project requirements without needing to invest in entirely new tooling for every design iteration.

Strategic Budgeting and Industry Recommendations for 2025

Understanding the price range of industrial 3D printers is vital for accurate capital expenditure planning. While desktop units may cost a few thousand dollars, true industrial-grade systems typically range from $20,000 to well over $250,000. This price variation is driven by factors such as material capabilities, build speed, and the level of internal sensor monitoring. When evaluating these costs, it is important to look beyond the initial purchase price and consider the total cost of ownership, including material expenses, maintenance contracts, and the specialized training required for staff.

For those seeking the best industrial 3D printers for recommendations, the market in 2025 emphasizes integrated ecosystems. Brands like Markforged have set a high bar by combining robust hardware with intuitive software that automates much of the print preparation process. These systems are often favored because they offer a seamless path from CAD design to finished part. Working with a knowledgeable partner can help a manufacturer determine if a specific Industrial 3D Printer aligns with their long-term growth strategy, especially when integrating with existing ERP or PDM systems.

Enhancing Workflow Through Software and Systems Integration

The hardware itself is only one part of the equation. To truly extract value from an industrial 3D printer, companies must ensure their software stack is fully optimized. Systems like SOLIDWORKS PDM allow for the secure management of design data, ensuring that the version sent to the printer is always the most current iteration. This prevents costly errors and ensures that the engineering team remains synchronized with the production floor. Furthermore, implementing simulation and fatigue-analysis services early in the design phase can predict how a 3D-printed part will perform in the real world, further justifying the investment in high-end additive technology.

Synthesizing Hardware Capabilities with Modern Manufacturing Strategy

The successful implementation of additive manufacturing relies on a holistic approach that views the industrial 3d printer not as an isolated tool, but as a critical node in a larger digital thread. By carefully evaluating build volumes, material requirements—ranging from a standard composite 3d printer to a heavy-duty metal 3d printer—and budget constraints, manufacturers can build a resilient production environment. The synergy between high-performance hardware and sophisticated CAD/PDM software enables a level of agility that was previously impossible.

Ultimately, the goal is to create a streamlined pipeline where ideas move rapidly from concept to reality. By partnering with experts who understand both the software side of design and the mechanical realities of printing, businesses can navigate the complexities of 2025’s manufacturing landscape. This integrated strategy ensures that every investment in technology contributes directly to improved efficiency, reduced lead times, and a stronger bottom line in an increasingly demanding global market. Mastering these interconnected themes is the definitive way to thrive in modern industry.

Additional Resources: