Delmiaworks

Table of Contents

DELMIAWorks: Empowering Modern Manufacturing

In today’s competitive landscape, manufacturers demand robust solutions to optimize operations and drive efficiency. delmiaworks stands out as a comprehensive manufacturing solution from Dassault Systèmes, rooted in the innovative 3DEXPERIENCE ecosystem. This integrated manufacturing platform combines DELMIAWorks ERP for seamless resource planning and DELMIAWorks MES for precise execution, enabling mid-market and enterprise manufacturers in sectors like aerospace and industrial equipment to achieve end-to-end visibility and control. By addressing common challenges such as data silos and inefficient workflows, it transforms fragmented processes into streamlined operations–for instance, unifying production data from design to delivery to reduce delays and errors.

At GSC 3D, we specialize in DELMIAWorks integration as an authorized partner, delivering nationwide implementation and support services. Our expertise ensures smooth deployments alongside tools like SOLIDWORKS PDM, creating unified workflows that enhance collaboration and data accuracy. We help manufacturers overcome inefficiencies by customizing solutions that align with their unique needs, from production planning to quality management. As noted in Capterra’s ERP software overview, over 70% of manufacturers are adopting integrated platforms to boost productivity, underscoring the value we bring through our proven DELMIAWorks implementations.

This guide explores DELMIAWorks fundamentals, including core modules for production and quality; integration strategies with CAD systems; practical applications in real-world scenarios; and advanced tactics for maximizing ROI. Whether you’re evaluating options or seeking to enhance your current setup, our insights will equip you with the knowledge to leverage this Dassault manufacturing solution effectively, positioning your operations for sustained success.

Fundamentals of DELMIAWorks ERP and MES Systems

DELMIAWorks represents a powerful enterprise resource platform designed specifically for manufacturing operations, enabling companies to streamline processes from planning to execution. As an authorized integrator, we at GSC 3D specialize in deploying DELMIAWorks to help US manufacturers achieve greater efficiency and visibility. This section explores the core components of DELMIAWorks ERP and MES systems, highlighting their roles in modern production environments.

ERP Fundamentals

At its core, DELMIAWorks ERP serves as the backbone for resource allocation and strategic planning in manufacturing. It integrates financials, supply chain management, and production scheduling into a unified system, allowing businesses to forecast demand, manage inventory, and optimize workflows. Key modules include:

- Inventory Control: Tracks materials in real-time to prevent stockouts and overages.

- Financial Management: Handles budgeting, costing, and reporting for accurate profitability analysis.

- Supply Chain Planning: Coordinates suppliers and logistics to ensure timely material availability.

These features address common pain points like fragmented data silos, providing executives with actionable insights. For instance, aerospace manufacturers can use DELMIAWorks ERP to align production schedules with complex part requirements, reducing planning errors by up to 30% based on industry benchmarks from sources like Capterra’s ERP adoption reports.

MES Fundamentals

Complementing the ERP, DELMIAWorks MES focuses on production monitoring and execution at the shop floor level. This manufacturing execution system captures real-time data from machines and operators, ensuring that plans translate into efficient output. Essential modules encompass:

- Production Monitoring: Oversees work orders and tracks progress to identify bottlenecks instantly.

- delmiaworks quality integration: Ensures compliance through automated inspections and defect tracking.

- Workforce Management: Schedules labor and monitors performance to maximize productivity.

By bridging the gap between planning and doing, DELMIAWorks MES enhances traceability, which is critical for industries like automotive where regulatory standards demand precise documentation.

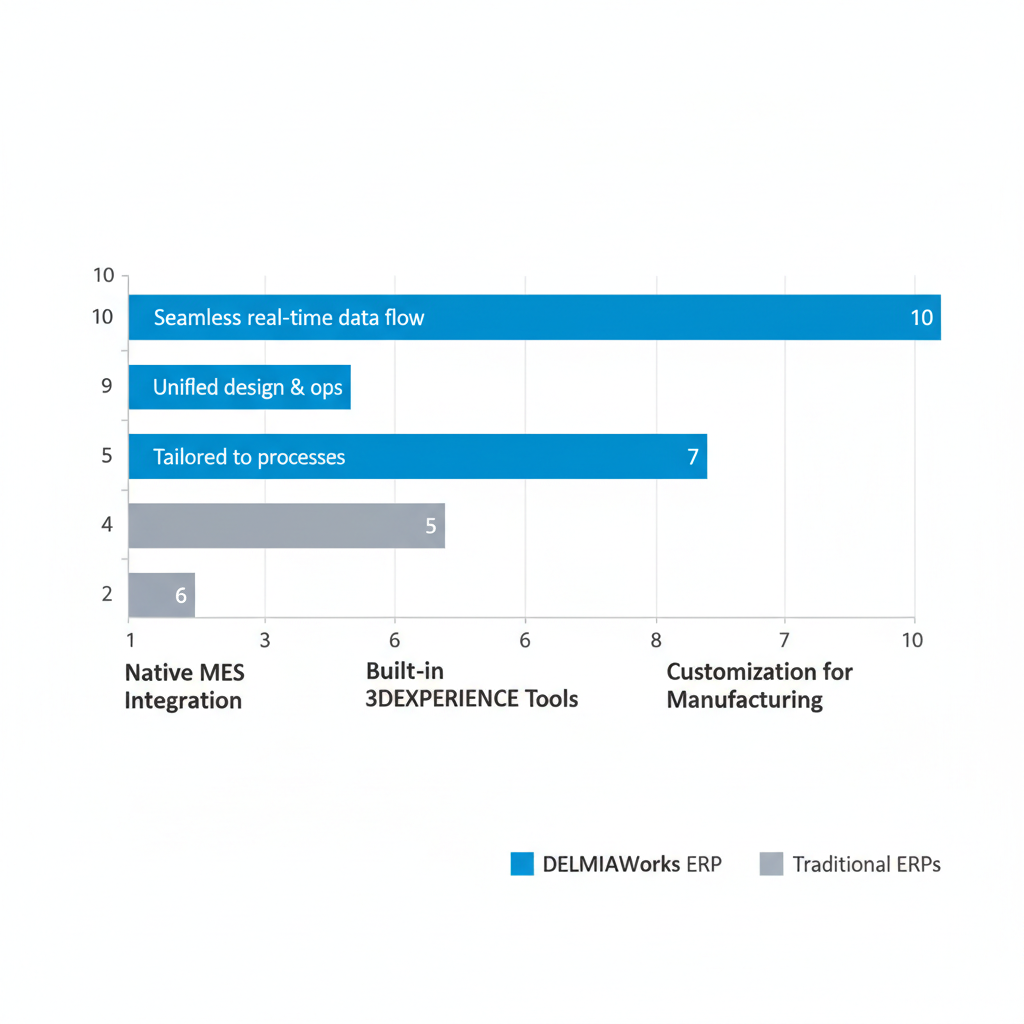

In many manufacturing setups, integrating ERP and MES systems poses significant challenges, such as data latency and compatibility issues that lead to operational silos. According to Capterra’s analysis of enterprise resource planning software, traditional ERPs often require custom add-ons for manufacturing-specific needs, complicating deployments and increasing costs. The following table illustrates these differences:

| Feature | DELMIAWorks ERP | Traditional ERPs (e.g., Generic Solutions) |

|---|---|---|

| Native MES Integration | Seamless ERP-MES connectivity for real-time data flow | Limited or add-on integrations |

| Built-in 3DEXPERIENCE Tools | Fully integrated for collaborative design and simulation | Requires third-party tools or manual syncing |

| Customization for Manufacturing | High; tailored for shop floor to executive visibility | General-purpose with moderate manufacturing adaptability |

This comparison underscores DELMIAWorks’ edge in native synergies, drawing from Capterra benchmarks where integrated solutions show 20-25% higher user satisfaction in manufacturing contexts. At GSC 3D, we recommend starting with a comprehensive assessment to tailor these features to your operations, ensuring smooth DELMIAWorks integration that minimizes downtime.

Building on this foundation, the combined ERP and MES capabilities of DELMIAWorks deliver transformative benefits, such as improved traceability and reduced downtime through end-to-end visibility. Manufacturers can achieve faster decision-making, with examples from industrial equipment sectors showing up to 15% cycle time reductions post-implementation. We at GSC 3D provide training and support to maximize these advantages, including initial assessments that align systems with SOLIDWORKS workflows for seamless data flow.

DELMIAWorks ERP vs. traditional systems feature comparison chart

In-Depth Exploration of DELMIAWorks Integration Capabilities

DELMIAWorks stands out as a unified manufacturing ecosystem that bridges critical systems for enhanced operational efficiency. At GSC 3D, we’ve implemented numerous DELMIAWorks integrations to help manufacturers streamline their processes from design to delivery. This section explores the platform’s robust integration capabilities, emphasizing how DELMIAWorks ERP and DELMIAWorks MES work together to create an integrated production platform. By leveraging the 3DEXPERIENCE platform, DELMIAWorks enables seamless connectivity, reducing silos and fostering real-time collaboration across teams.

Seamless ERP and MES Synchronization

DELMIAWorks unifies ERP and MES functions through advanced synchronization protocols, ensuring real-time data exchange between planning and execution layers. This integration allows production schedules from the ERP side to instantly update MES shop floor controls, minimizing delays and errors in manufacturing workflows. Key protocols include API-based connectors and event-driven messaging, which facilitate bidirectional data flow for inventory levels, work orders, and quality metrics. For instance, when a production order is released in DELMIAWorks ERP, the MES component automatically adjusts machine assignments and material allocations on the floor.

The benefits for production control are significant, including improved accuracy in forecasting and reduced lead times. According to insights from the DELMIA blog on cost-effective MES-ERP solutions, this synchronization can cut integration costs by up to 30% compared to custom builds, while enhancing visibility into operational bottlenecks. We’ve seen clients achieve greater agility by automating routine updates, allowing teams to focus on strategic decisions rather than manual reconciliations.

One common challenge is ensuring data consistency during high-volume operations, which DELMIAWorks addresses through robust error-handling mechanisms and validation rules. At GSC 3D, our implementation teams configure these protocols to align with specific client needs, often incorporating custom triggers for peak production periods.

| Aspect | DELMIAWorks | Standalone ERP/MES |

|---|---|---|

| Data Synchronization Speed | Real-time via 3DEXPERIENCE | Batch processing, delays up to hours |

| SOLIDWORKS Compatibility | Native API connections | Requires third-party middleware |

| Deployment Complexity | Moderate with GSC support; high without | High, custom coding often needed |

Integration with SOLIDWORKS and PDM Systems

DELMIAWorks compatibility with SOLIDWORKS streamlines design-to-manufacturing workflows by enabling direct data transfer from CAD models to production plans. This integration leverages SOLIDWORKS PDM for centralized file management, where engineering changes propagate seamlessly to DELMIAWorks modules. For example, a revised part design in SOLIDWORKS updates the bill of materials in DELMIAWorks ERP automatically, triggering MES adjustments for machining paths.

GSC 3D deployment strategies emphasize solidworks automation add-ins to enhance this flow, automating repetitive tasks like data validation and export routines. Our approach includes API setups that connect PDM vaults to DELMIAWorks, ensuring version control and audit trails across the pipeline. This reduces errors in handover phases, as we’ve implemented in automotive clients where design iterations directly inform shop floor simulations.

Potential challenges, such as API latency during large file transfers, are mitigated through optimized connectors and cloud-based caching on the 3DEXPERIENCE platform. The DELMIA blog highlights how such integrations foster a unified ecosystem, quoting that “real-time PDM-ERP links can accelerate time-to-market by 20%”. We at GSC 3D tailor these strategies to include training on automation tools, empowering teams to maintain the integration post-deployment.

End-to-End Visibility Features

DELMIAWorks provides comprehensive tools for monitoring across the supply chain, with dashboards that aggregate data from ERP, MES, and external sources for holistic oversight. These features include customizable analytics panels that track KPIs like on-time delivery rates and inventory turnover, offering real-time insights into bottlenecks from procurement to shipping.

Analytics capabilities extend to predictive modeling, where historical data informs future planning, helping manufacturers anticipate disruptions. For shop floor visibility, interactive heat maps display machine utilization, while supply chain views integrate vendor performance metrics. As noted in DELMIA’s resources on MES-ERP integration, these tools enhance decision-making by providing “actionable intelligence that reduces downtime by 15-25%”.

| Aspect | DELMIAWorks | Standalone ERP/MES |

|---|---|---|

| Dashboard Customization | Fully configurable via 3DEXPERIENCE | Limited, vendor-specific templates |

| Real-Time Analytics | Integrated AI predictions | Periodic reports, less dynamic |

| Supply Chain Integration | Native connectors to partners | Manual imports, error-prone |

Practical Applications and Implementation of DELMIAWorks

At GSC 3D, we have witnessed DELMIAWorks transform manufacturing operations for our clients in aerospace and automotive sectors. This powerful solution combines DELMIAWorks ERP for comprehensive planning with DELMIAWorks MES for real-time execution, enabling practical manufacturing execution that drives operational excellence. As a trusted partner, we emphasize deployment strategies tailored to mid-market needs, ensuring seamless integration with tools like SOLIDWORKS. Our approach focuses on hands-on applications that deliver measurable improvements in shop floor control and overall efficiency.

Shop Floor Management with DELMIAWorks MES

DELMIAWorks MES serves as the backbone for effective shop floor management, providing manufacturers with tools to monitor and control daily operations in real time. In aerospace facilities, for instance, our clients use DELMIAWorks MES to track work-in-progress items, ensuring compliance with stringent quality standards. A leading automotive parts producer we supported implemented this system to oversee assembly lines, reducing downtime by coordinating machine schedules and operator tasks dynamically.

Implementation Best Practices and GSC 3D Support

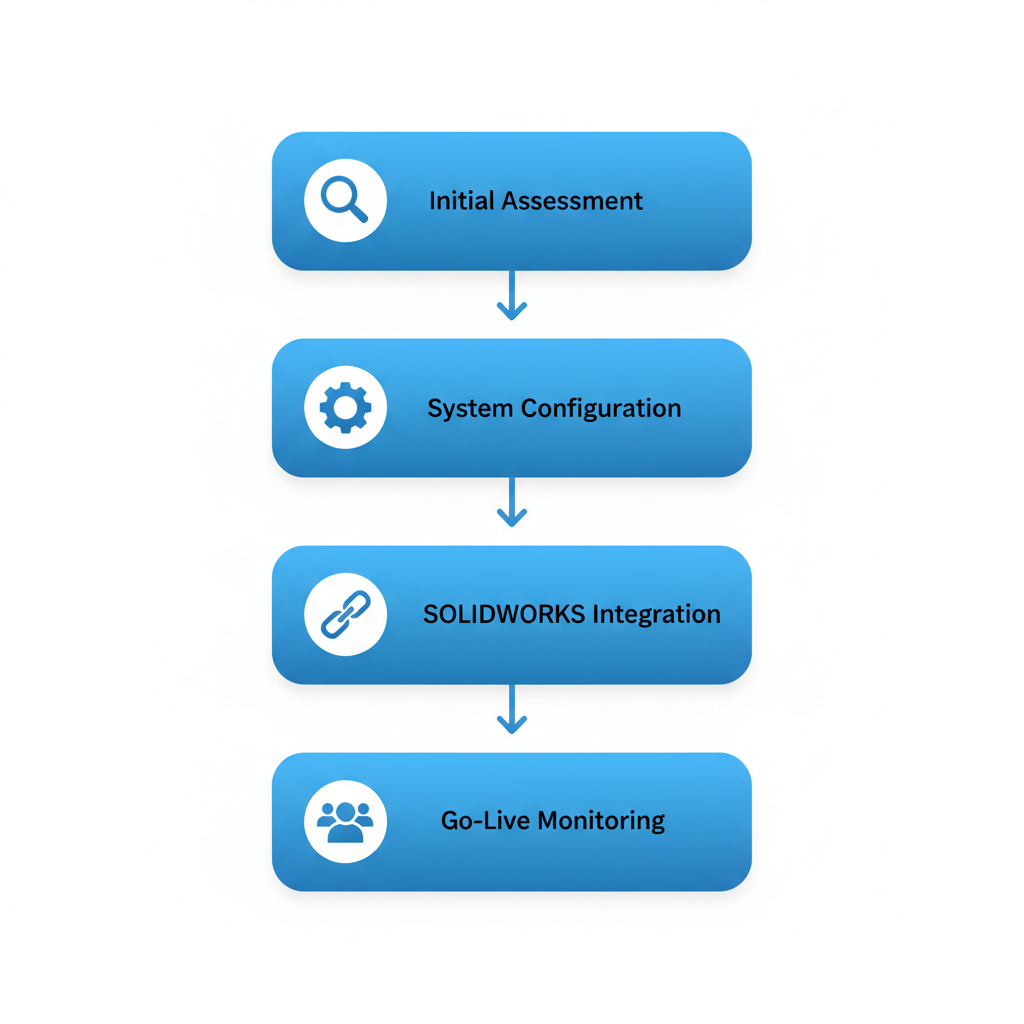

Implementing DELMIAWorks requires a structured roadmap to maximize ROI, and at GSC 3D, we guide clients through every phase with our expertise in DELMIAWorks integration. The process begins with an initial assessment to evaluate current workflows and identify integration points with DELMIAWorks ERP.

- Conduct a thorough needs analysis with stakeholders.

- Customize modules for shop floor and inventory management.

- Integrate with SOLIDWORKS PDM for design-to-production continuity.

- Deliver hands-on training through our SOLIDWORKS CAD Manager’s Bootcamp, adapted for DELMIAWorks users.

- Go live with phased rollout and ongoing support.

DELMIAWorks implementation process steps visualization

| Feature | On-Premise | Cloud | Hybrid (DELMIAWorks) |

|---|---|---|---|

| Customization Level | High but IT-heavy | Medium, subscription-based | Balanced, scalable |

| Scalability | Limited by hardware | High, on-demand | Flexible, as-needed growth |

| Integration Ease | Seamless with SOLIDWORKS | API-dependent | Optimized for ERP/MES sync |

Production Monitoring and Efficiency Gains

DELMIAWorks excels in production monitoring, offering real-time tools that track key performance indicators across manufacturing lines. Our clients in electronics assembly use these features to monitor cycle times and yield rates, enabling proactive interventions that boost output. Overall, delmiaworks manufacturing growth becomes evident as facilities scale operations with confidence.

Advanced Features and Strategic Advantages of DELMIAWorks

DELMIAWorks elevates manufacturing operations beyond basic ERP functionalities, offering strategic manufacturing intelligence through its enterprise-grade platform. As a trusted partner, we at GSC 3D specialize in DELMIAWorks integration, helping US manufacturers harness advanced tools for predictive analytics, global scalability, and tailored customization.

| Feature | Basic ERP | DELMIAWorks Advanced |

|---|---|---|

| AI-Driven Analytics | Limited reporting | Predictive forecasting and AI insights |

| Global Supply Chain Visibility | Regional focus | Comprehensive 3DEXPERIENCE integration |

| Customization Options | Standard modules | Industry-specific modules |

Customization in DELMIAWorks offers industry-specific modules that adapt to unique manufacturing needs, far exceeding generic ERP templates. We emphasize strategic depth in our DELMIAWorks implementations, including:

- Advanced quality control modules for real-time defect detection

- Simulation synergies for process validation

- MES extensions for execution monitoring

By partnering with GSC 3D, manufacturers unlock subscription benefits like dedicated support and training, ensuring maximum value from this robust platform.

Frequently Asked Questions About DELMIAWorks

What is the typical timeline for DELMIAWorks implementation?

Implementation timelines vary based on company size and complexity, typically ranging from 3 to 12 months.

How does DELMIAWorks integrate with SOLIDWORKS?

DELMIAWorks ERP seamlessly syncs with SOLIDWORKS for design-to-production workflows, reducing data silos. This integration can lead to solidworks hardware savings through optimized resource use.

What are the benefits of DELMIAWorks MES?

DELMIAWorks MES enhances real-time shop floor visibility, improves quality control, and boosts operational efficiency by up to 20% in many cases.

Leveraging DELMIAWorks for Manufacturing Success

DELMIAWorks transforms manufacturing by unifying ERP and MES systems, providing real-time visibility into operations and enhancing efficiency across production processes.

Resources