Twin Cities, Minnesota

Wednesday, August 31

10:00 am - 2:00 pm CDT

How do you Print Money? Adding 3D Printing to your Shop will help improve your Efficiencies and ROI

Come meet up with GSC, Ellison Technologies, and Markforged to see how 3D printing can integrate into your shop floor and enhance your CNC machining, cobot automation, and inspection equipment. At the event, GSC will discuss how Markforged technologies integrate into your workflow using DNSolutions machinery, SOLIDWORKS, Cobot automation, and metrology.

You’ll also learn more about:

- Eiger™ - is the engine of our platform — a secure software interface that's as powerful as it is accessible.

- Blacksmith - End-to-end solution for validating quality as you print so parts can be used immediately after printing.

- Materials - From rapid prototyping to production-grade parts, come check out our range of plastics, metals, and continuous fiber composite materials

- Printers - Industrial 3D printers that consistently improve with a connected platform and precision construction.

Markforged Application Spotlights

Lean Machine CNC

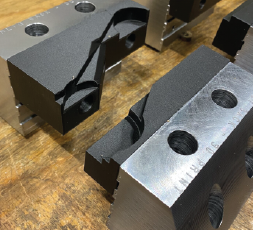

Lean Machine is a metal fabrication job shop specializing in custom machining with a 5-axis CNC mill. The company uses 3D printing to create custom vise and soft jaws, allowing them to take on more complex jobs and make faster, more accurate, and non-marring parts.

MF Precision

The MF Precision team has utilized their printers for carbon-fiber reinforced soft jaws to hold a prototype part with fantastic results. Before bringing on their Markforged printers, MF Precision would have quoted a 3-6 week lead time for these soft jaws — leading to a potential loss of contract.

Markforged 3D Printing

Markforged 3D printers deliver the highest quality of parts—precise, repeatable, and strong. Composite 3D printing provides the strength you need for tooling and functional parts.

Can't Make One of These Events?

Talk with our experts or schedule an in-person demo at our Germantown Technology Center.