Your Challenges, One Integrated Solution

Efficiency Starts with the Right Solutions

🔹 Manufacturing-Ready

Problem it Solves:

Teams struggle to hand off designs from engineering to the shop floor. Misaligned data, version confusion, and disconnected workflows can delay production.

How It Helps:

PDM and CAM fully integrate into SOLIDWORKS, your designs, files, and toolpaths are always in sync. You’ll reduce bottlenecks, ensure the right data hits the shop floor every time, and speed up production without sacrificing quality.

Result:

Eliminate costly errors, cut cycle times, and deliver finished products faster.

🔹 Design Validation

Problem it Solves:

Testing prototypes physically is expensive and time-consuming. Many engineers overbuild for safety or waste resources chasing trial-and-error solutions.

How It Helps:

SOLIDWORKS Simulation lets you test product strength, airflow, motion, and performance virtually before creating a physical prototype. By identifying flaws early, you avoid rework and reduce the need for costly iterations

Result:

Save time, cut material costs, and build with confidence knowing your design is validated before it leaves CAD.

🔹 Electrical Integration

Problem it Solves:

Mechanical and electrical teams often work in silos, leading to mismatched designs, late-stage integration issues, and data errors.

How It Helps:

This solution unifies mechanical and electrical design in one environment. Shared libraries, real-time collaboration, and PDM-backed data integrity ensure your electrical and mechanical designs stay perfectly aligned.

Result:

Minimize integration errors, speed up development cycles, and deliver fully synchronized designs the first time.

🔹 Tooling & Fixture Design

Problem it Solves:

Tooling and fixture creation often stalls production, with delays from outsourcing, validation issues, or weak designs that fail under pressure.

How It Helps:

By combining CAD, additive manufacturing, and CAM, you can design, test, and validate tools and fixtures in-house. Simulate tool paths, verify strength, and 3D print production-ready fixtures with Markforged’s high-strength materials.

Result:

Slash lead times, reduce outsourcing costs, and move from concept to validated production tools at record speed.

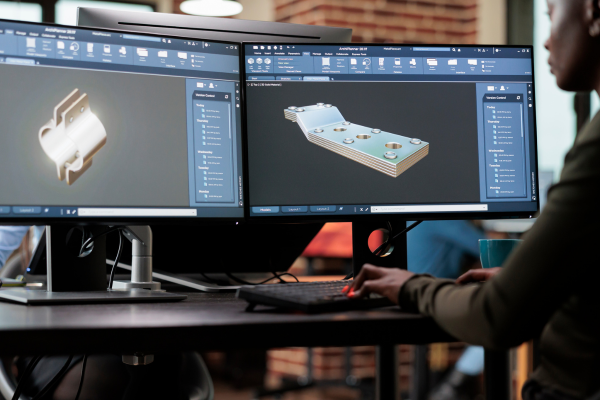

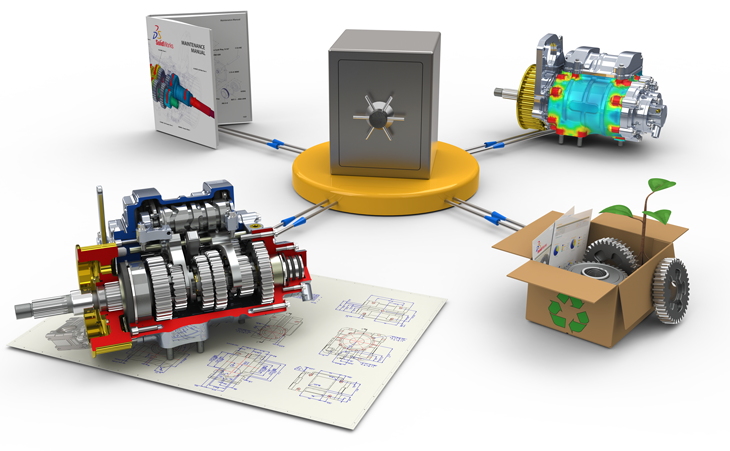

The Power of the Full Suite

Modern manufacturing demands more than design alone. Engineering teams need tools that streamline production handoffs, ensure data integrity, and validate performance before a single part is made. Disconnected systems introduce errors, delays, and added cost.

That’s why GSC delivers end-to-end SOLIDWORKS solutions—integrating CAD, PDM, Simulation, Electrical, and CAM into one unified environment. The result: faster iterations, stronger collaboration, and a product development process that’s optimized from concept through production.

See the Value in Action

Time Savings

Faster design cycles: Engineers can move from concept to production in fewer steps, thanks to connected design and manufacturing workflows.

Eliminate rework: Built-in validation tools and synchronized data drastically reduce errors that cause costly do-overs.

Shorter lead times: Integrated CAM and additive manufacturing options help you cut days or weeks off tooling and prototyping.

Cost Savings

Lower prototyping costs: Test virtually instead of relying solely on physical prototypes. Many customers report cutting prototype expenses by 50% or more.

Less scrap and waste: Simulation and CAM optimization reduce material waste during production.

Reduced outsourcing: In-house tooling, fixtures, and validation keep more of your process (and dollars) under your control.

Reduce Risk

Design with confidence: Catch weak points, stress failures, and airflow inefficiencies before production.

Data integrity: PDM ensures the right version is always in use, reducing costly errors on the shop floor.

Cross-team alignment: Electrical and mechanical teams stay connected, avoiding late-stage integration surprises.

fill

Scalability & Growth

Flexible licensing: Scale your software investment with your business, thanks to GSC’s multi-license promotions.

Future-ready workflows: The SOLIDWORKS ecosystem grows with your company, adding functionality as your needs evolve.

Training ROI: With 25% off training, your team levels up faster, maximizing software usage and shortening the path to payback.