Key Benefits of 3D Printing in Automation

Achieve operational excellence with on-demand, high-performance parts.

Reduced Downtime

Quickly print custom jigs, fixtures, and tooling in-house to avoid long lead times and keep your production line running smoothly.

Cost-Effective Production

Eliminate costly machining or outsourcing by creating end-use parts that meet your exact needs at a fraction of the cost.

High Strength Materials

Markforged’s advanced composite and metal materials ensure your parts can withstand the harsh environments of automated systems.

Increased Flexibility & Customization

Easily customize and iterate on designs, allowing for rapid adaptation to changing production needs without lengthy delays.

Automation applications

Discover how our 3D printers are used to optimize automated systems across industries.

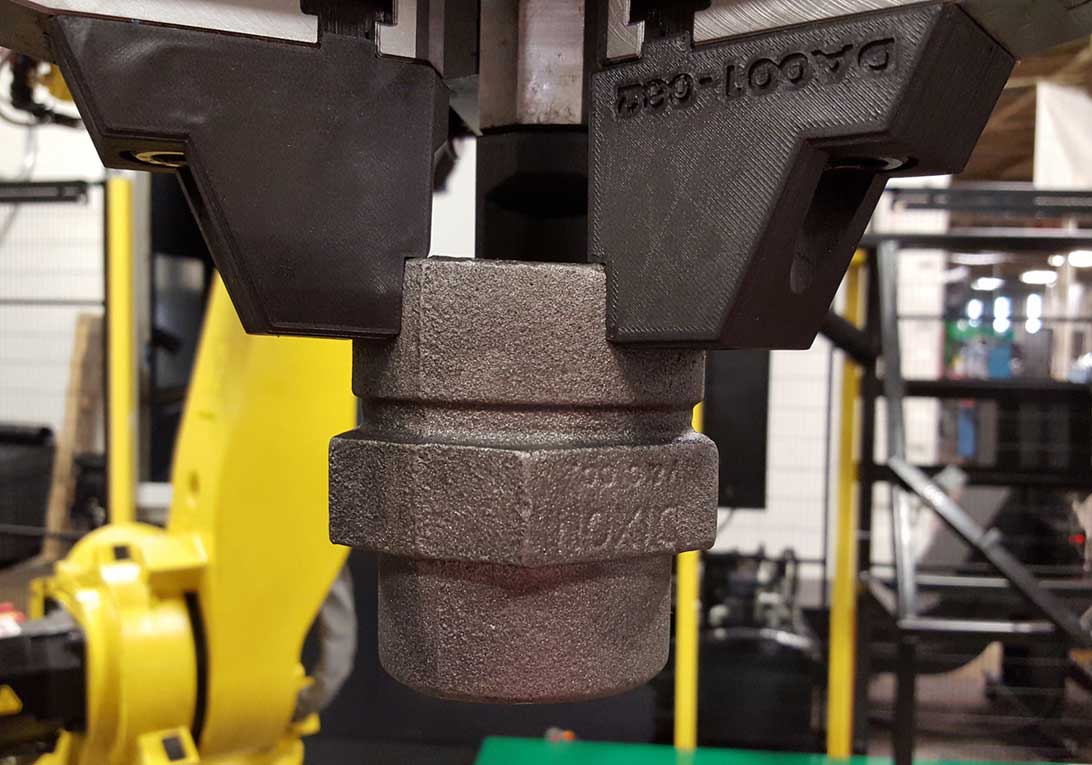

Robotic Tooling

Print end-effectors, grippers, and mounts for robotic arms that are lightweight, strong, and tailored to your specific operations.

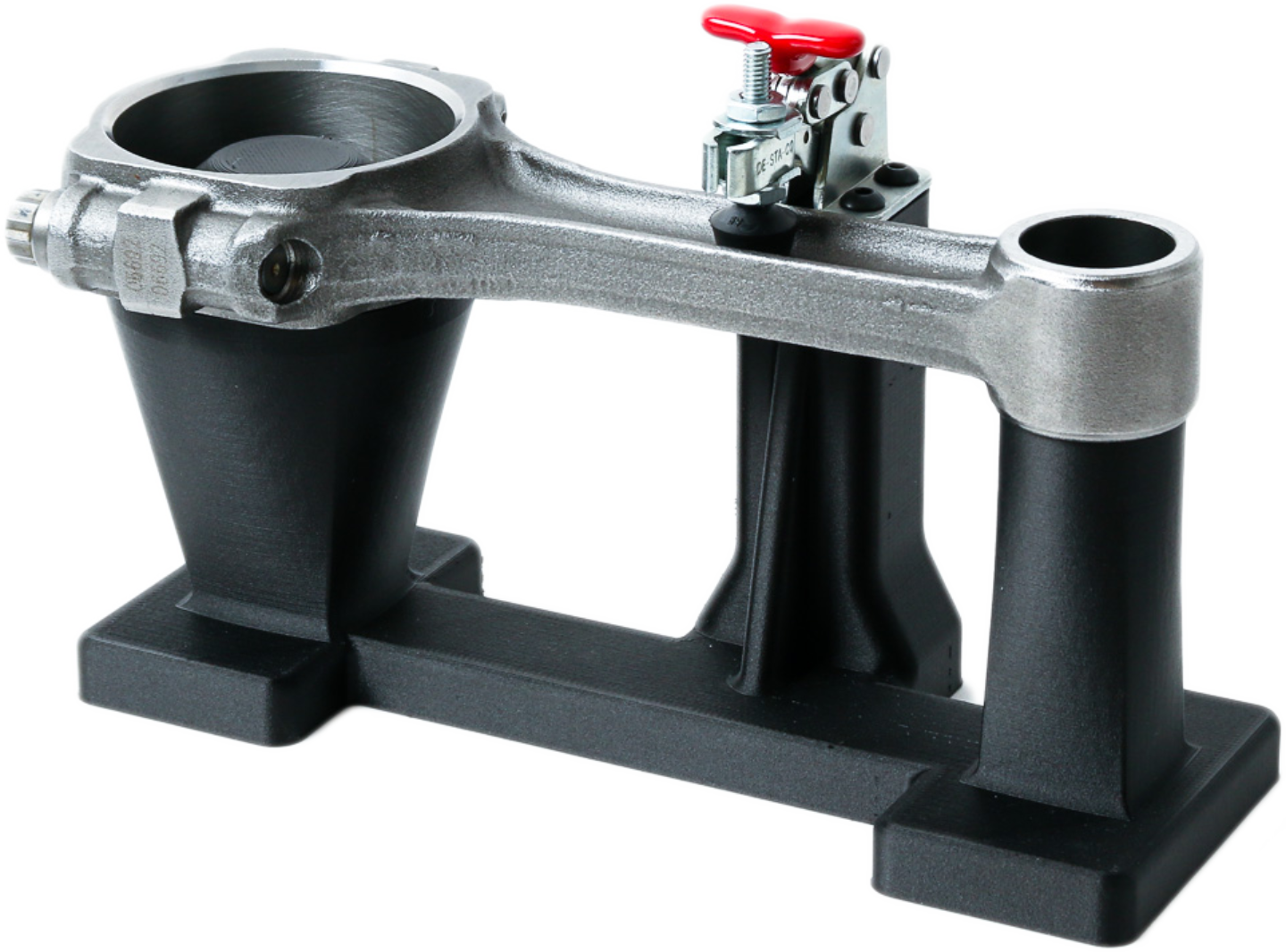

Custom Fixtures & Jigs

Streamline assembly processes with custom fixtures and jigs printed on-demand for your automation systems.

Sensor Housings and Brackets

Create durable, precise housings and brackets for sensors, cameras, and other components integrated into automated machinery.

MRO

Maximize uptake by printing high-performance replacement parts on-demand, to keep automated systems running longer.

Customer Success Stories

See how manufacturers like you are leveraging 3D printing to enhance efficiency and reduce costs in their automated processes.

HellermannTyton's successful integration of 3D printing into their Automation department has transformed their productions process. The use of a Markforged X7 printer allowed them to reduce costs, accelerate production times, and improve flexibility in part design.

High precision, durability, and speed were lacking, creating several challenges that affected production efficiency and customers satisfaction. With Markforged 3D Printers, Dynamac now produces parts taht are durable enough to withstand the rigors of the factory floor while maintaining tight tolerance.

A traditional robotic production line requires multiple expensive robot cells, because each can only perform one task. Strong, lightweight custom end effectors made by Markforged 3D printers add customization to a standardized platform. Now, ProCobots streamlines its customers’ manufacturing workflows by minimizing overhead and maximizing effectiveness.

High-precision robotic systems needing precise optimization were being held up by a long fabrication cycle. 3D printed functional prototypes allow engineers to test parts before implementing costly fabrication methods. Now, Brooks’ prototyping iteration cycles has dropped from weeks to days.

Frequently Asked Questions

FAQs About 3D Printing in Automation

Our parts, reinforced with continuous carbon fiber, offer metal-like strength, perfect for high-demand environments.

Automotive, aerospace, consumer goods, electronics, and any industry relying on automated systems can benefit.

Depending on the complexity, most parts can be printed within hours or overnight.

Absolutely! We can help you design and print custom end-effectors, brackets, and more for your robotic systems.

Start creating high-quality, intricate patterns while reducing production time and costs