Robotics & Virtual Factories

Maximize your equipment investments and production improvements with Factory Automation. Design, validate, and optimize automation concepts virtually before purchasing hardware or changing facility layouts. With simulation capabilities, you can improve production efficiency and meet demands.

ROBOTICS

Robotic Simulation Software

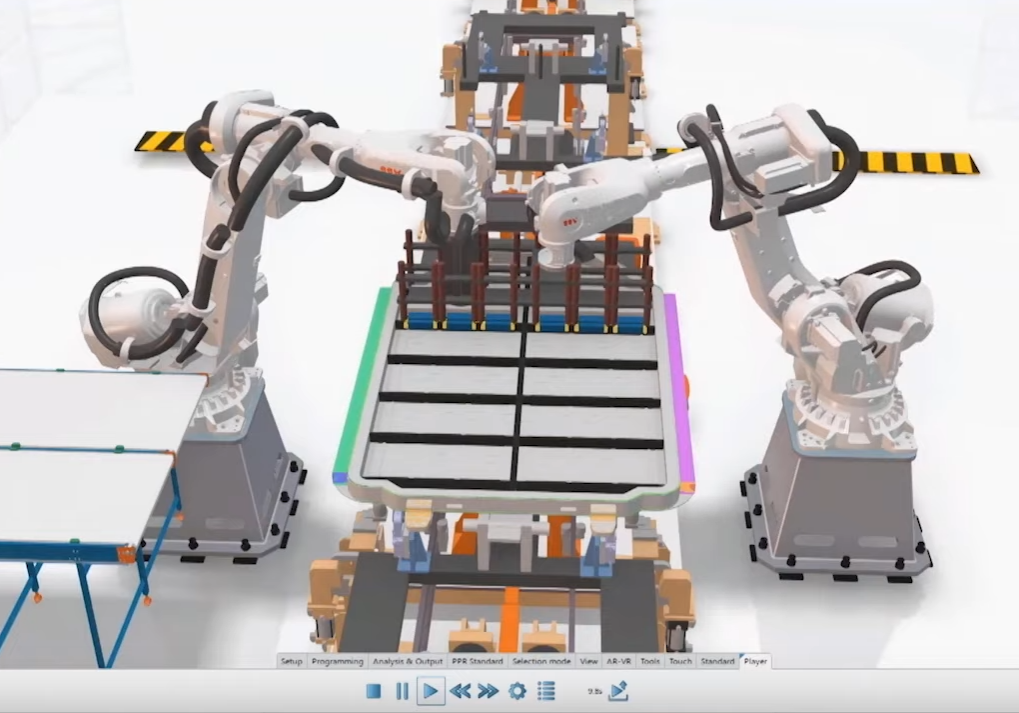

Build, simulate, validate, and program industrial robot workcells before they are implemented in the real world. Perform what-if scenarios and plan the layout of single or multiple workcells before installing or purchasing additional machinery.

- Comprehensive and robust set of capabilities to help layout and program robotic systems more safely and efficiently

- Simplifies end-to-end manufacturing engineering processes, including layout, simulation, validation, calibration, and offline robot programming information saved on the 3DEXPERIENCE Platform

- Best for arc welding, adhesives, machine tending, pick & place applications

- Includes robot library & robot translators

- Offline programming in native robot language

- Import your current robot programs

VIRTUAL FACTORY

Factory Layout

Analyze the movement of the equipment and robotics to determine where to place the machinery, allowing the most production. Evaluate multiple what-if scenarios enabling the customer to make business decisions with confidence.

VIRTUAL FACTORY

Factory Flow Simulation

Create 3D layout from existing factory by importing a cloud of points, simulate product scenarios to predict production rate and visualize the flow of the floor to identify bottlenecks. Run “What If” Simulations to improve system performance and production rates.

Factory Automation Roles

DELMIA Factory Automation is organized into Roles to help you get up to speed and operate more effectively.

Robot Programmer

Build, Simulate, Validate and Program Industrial Robot workcells.

Factory Simulation Engineer

Simulate material flow and resource utilization in a Virtual Factory context.

Robotics Virtual Commissioning Analyst

Execute virtual commissioning scenarios on a Manufacturing virtual twin with accurate simulations of Robots, equipment and sensors connected to a PLC program.

Shop Floor Equipment Engineer

Create a virtual twin experience of factory machines using any CAD data.